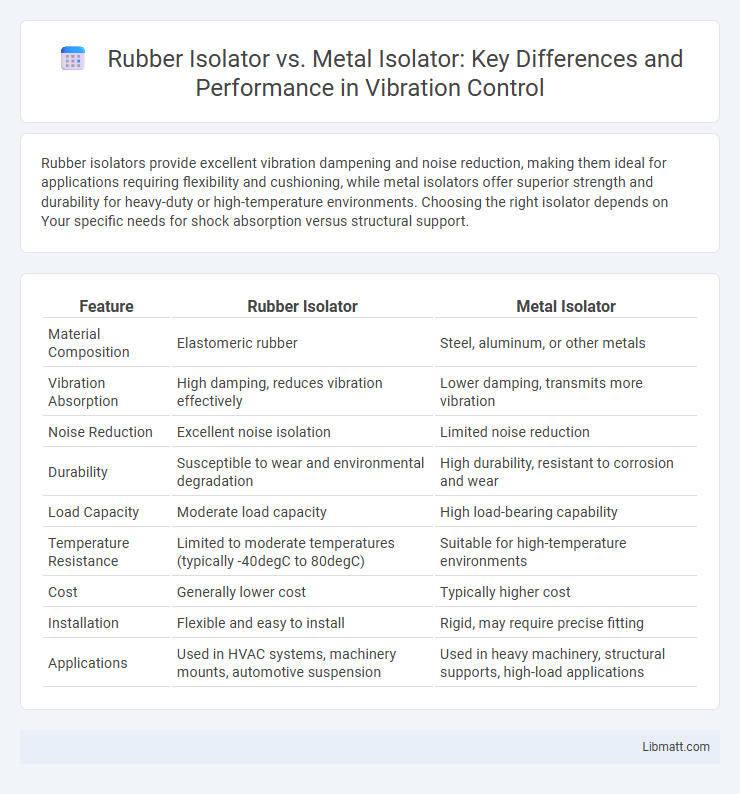

Rubber isolators provide excellent vibration dampening and noise reduction, making them ideal for applications requiring flexibility and cushioning, while metal isolators offer superior strength and durability for heavy-duty or high-temperature environments. Choosing the right isolator depends on Your specific needs for shock absorption versus structural support.

Table of Comparison

| Feature | Rubber Isolator | Metal Isolator |

|---|---|---|

| Material Composition | Elastomeric rubber | Steel, aluminum, or other metals |

| Vibration Absorption | High damping, reduces vibration effectively | Lower damping, transmits more vibration |

| Noise Reduction | Excellent noise isolation | Limited noise reduction |

| Durability | Susceptible to wear and environmental degradation | High durability, resistant to corrosion and wear |

| Load Capacity | Moderate load capacity | High load-bearing capability |

| Temperature Resistance | Limited to moderate temperatures (typically -40degC to 80degC) | Suitable for high-temperature environments |

| Cost | Generally lower cost | Typically higher cost |

| Installation | Flexible and easy to install | Rigid, may require precise fitting |

| Applications | Used in HVAC systems, machinery mounts, automotive suspension | Used in heavy machinery, structural supports, high-load applications |

Introduction to Vibration Isolators

Vibration isolators are essential components designed to reduce the transmission of mechanical vibrations between equipment and their mounting surfaces, enhancing performance and longevity. Rubber isolators provide excellent damping properties and flexibility, making them ideal for absorbing shock and isolating low to medium frequency vibrations. Metal isolators, often made from steel or stainless steel, offer superior load-bearing capacity and durability, suitable for high-frequency vibrations and harsh environments where rubber may degrade.

Key Differences: Rubber vs. Metal Isolators

Rubber isolators offer excellent vibration damping and noise reduction due to their flexible and elastic properties, making them ideal for applications requiring shock absorption and minimal metal-to-metal contact. Metal isolators provide superior load-bearing capacity, durability, and high-temperature resistance, suitable for heavy machinery and structural applications where stiffness and strength are critical. Your choice between rubber and metal isolators depends on factors like vibration frequency, environmental conditions, and load requirements to optimize performance and longevity.

Material Properties and Performance

Rubber isolators excel in vibration damping due to their high elasticity and excellent energy absorption, making them ideal for reducing noise and shock in sensitive equipment. Metal isolators, composed of steel or aluminum alloys, provide superior load-bearing capacity and durability but offer less flexibility and vibration attenuation compared to rubber. Your choice depends on balancing the need for flexibility and cushioning with structural strength and lifespan requirements.

Applications of Rubber Isolators

Rubber isolators are widely used in automotive, industrial machinery, and electronic equipment to absorb vibrations and reduce noise, enhancing operational stability and extending component lifespan. Their flexibility and damping properties make them ideal for protecting sensitive instruments from shock and impact in sectors such as aerospace and medical devices. Compared to metal isolators, rubber isolators excel in environments requiring elasticity and resilience against repetitive vibrations.

Applications of Metal Isolators

Metal isolators are widely used in heavy machinery and automotive industries where high load-bearing capacity and durability under extreme conditions are essential. They effectively reduce vibration and shock in applications such as engine mounts, industrial equipment, and aerospace components. Their resistance to harsh environmental factors makes them ideal for outdoor and high-temperature environments.

Load Capacity and Durability Comparison

Rubber isolators provide excellent vibration damping with moderate load capacity, making them ideal for applications requiring flexibility and noise reduction. Metal isolators offer higher load capacity and superior durability under extreme environmental conditions, but with less effective vibration absorption. Selecting between these depends on balancing the need for load-bearing strength versus long-term resilience and isolation performance.

Temperature and Environmental Resistance

Rubber isolators offer superior flexibility and excellent resistance to a wide range of temperatures, typically from -40degC to 120degC, making them ideal for environments with temperature fluctuations and exposure to moisture, oils, and chemicals. Metal isolators, while providing high mechanical strength and durability, often have limited corrosion resistance unless treated or coated, and their performance can be affected by extreme temperatures that cause metal fatigue or deformation. Selecting between rubber and metal isolators depends on environmental conditions, with rubber preferred for environments requiring vibration damping and chemical resistance, and metal suited for high-load applications with less exposure to corrosive elements.

Maintenance and Lifespan Considerations

Rubber isolators generally require less maintenance due to their ability to absorb vibrations and resist corrosion, extending their effective lifespan in dynamic environments. Metal isolators, while more durable under extreme loads and temperatures, may demand regular inspections and potential corrosion treatment to maintain optimal performance. Choosing the right isolator depends on your specific application needs, balancing maintenance efforts with expected longevity.

Cost Efficiency and Value Analysis

Rubber isolators often provide superior cost efficiency due to their lower material and manufacturing expenses, making them ideal for budget-sensitive projects requiring vibration damping and noise reduction. Metal isolators offer enhanced durability and load-bearing capacity, delivering long-term value in heavy-duty applications where maintenance and replacement costs must be minimized. Your choice should balance initial investment with expected performance lifespan to maximize overall value in specific operational environments.

Choosing the Right Isolator for Your Needs

Rubber isolators provide superior vibration dampening and noise reduction, making them ideal for applications requiring flexible support and shock absorption. Metal isolators offer higher load capacity and durability under extreme temperatures and heavy mechanical stress, suitable for industrial machinery and structural components. Selecting the right isolator depends on balancing vibration isolation efficiency with load requirements and environmental conditions to ensure optimal performance and longevity.

Rubber Isolator vs Metal Isolator Infographic

libmatt.com

libmatt.com