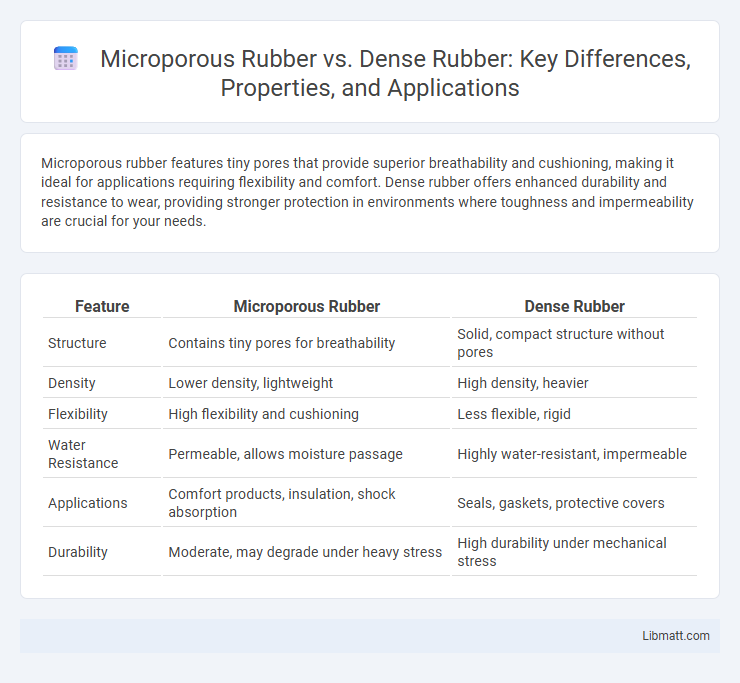

Microporous rubber features tiny pores that provide superior breathability and cushioning, making it ideal for applications requiring flexibility and comfort. Dense rubber offers enhanced durability and resistance to wear, providing stronger protection in environments where toughness and impermeability are crucial for your needs.

Table of Comparison

| Feature | Microporous Rubber | Dense Rubber |

|---|---|---|

| Structure | Contains tiny pores for breathability | Solid, compact structure without pores |

| Density | Lower density, lightweight | High density, heavier |

| Flexibility | High flexibility and cushioning | Less flexible, rigid |

| Water Resistance | Permeable, allows moisture passage | Highly water-resistant, impermeable |

| Applications | Comfort products, insulation, shock absorption | Seals, gaskets, protective covers |

| Durability | Moderate, may degrade under heavy stress | High durability under mechanical stress |

Introduction to Microporous and Dense Rubber

Microporous rubber features a network of tiny air-filled cells that provide excellent flexibility, cushioning, and breathability, making it ideal for applications requiring shock absorption and insulation. Dense rubber, in contrast, is solid and compact, offering superior strength, durability, and resistance to wear, chemicals, and weathering, suited for heavy-duty industrial uses. Understanding the differences between microporous and dense rubber helps you select the best material based on performance requirements such as elasticity, durability, and environmental exposure.

Key Differences Between Microporous and Dense Rubber

Microporous rubber features a network of interconnected microscopic pores, resulting in enhanced flexibility, superior breathability, and improved cushioning compared to dense rubber. Dense rubber is solid and non-porous, providing higher strength, greater durability, and excellent resistance to chemicals and abrasion. The choice between microporous and dense rubber primarily depends on the application requirements for breathability versus toughness and wear resistance.

Physical Properties Comparison

Microporous rubber features a network of tiny pores, resulting in lightweight, enhanced flexibility, and improved breathability compared to dense rubber's solid, compact structure that offers superior strength, durability, and resistance to wear. Dense rubber exhibits higher tensile strength and better resistance to chemicals and abrasion, making it suitable for heavy-duty applications, while microporous rubber provides cushioning and shock absorption ideal for lightweight protective gear. You can choose microporous rubber for comfort and flexibility or dense rubber for maximum durability and toughness depending on your application needs.

Applications of Microporous Rubber

Microporous rubber is widely used in applications requiring enhanced breathability and cushioning, such as medical seals, gaskets, and flexible diaphragms. Its unique porous structure allows for excellent air and fluid permeability, making it ideal for filtration systems and soundproofing materials. Your projects benefiting from lightweight, flexible, and breathable materials can leverage microporous rubber's distinct advantages over dense rubber.

Applications of Dense Rubber

Dense rubber is widely used in applications requiring high durability, chemical resistance, and airtight sealing, such as automotive gaskets, industrial hoses, and vibration isolators. Its non-porous structure provides excellent resistance to oils, fuels, and harsh chemicals, making it ideal for sealing and insulating components in engines and machinery. Dense rubber's strength and impermeability also allow it to be used in electrical insulation, protective coverings, and heavy-duty flooring where moisture and abrasion resistance are critical.

Performance in Various Industries

Microporous rubber excels in industries requiring high breathability and cushioning, such as footwear and medical devices, due to its lightweight structure and enhanced air permeability. Dense rubber offers superior durability, chemical resistance, and load-bearing capacity, making it ideal for automotive seals, industrial gaskets, and heavy machinery components. The choice between microporous and dense rubber depends on specific performance requirements like flexibility, resistance to environmental factors, and comfort in applications.

Durability and Longevity

Microporous rubber offers enhanced durability due to its ability to resist cracking and deformation under stress, extending its longevity in dynamic applications. Dense rubber exhibits superior abrasion resistance and tensile strength, making it highly durable in heavy-duty environments. The choice between microporous and dense rubber depends on specific use cases, with microporous rubber excelling in flexibility and dense rubber providing robust wear resistance.

Cost and Economic Considerations

Microporous rubber typically offers greater cost-efficiency due to its lighter weight and better insulating properties, which can reduce energy costs in industrial applications. Dense rubber, although more expensive upfront, provides superior durability and resistance to compression, potentially lowering replacement and maintenance expenses over time. Your choice between the two should balance initial investment with long-term operational savings to optimize economic benefits.

Environmental Impact and Sustainability

Microporous rubber offers enhanced breathability, reducing the need for synthetic additives and facilitating natural degradation, which improves its environmental sustainability compared to dense rubber. Dense rubber, while durable, often relies on extensive chemical treatments and fillers that can hinder biodegradability and increase its ecological footprint. Choosing microporous rubber helps minimize waste accumulation and lowers toxic emissions during production and disposal, aligning better with sustainable material goals.

Choosing the Right Rubber Type for Your Needs

Microporous rubber offers superior breathability and flexibility, making it ideal for applications requiring ventilation and comfort, such as medical gloves and wearable devices. Dense rubber provides enhanced durability and resistance to chemicals and abrasion, suitable for heavy-duty industrial seals and gaskets. Your choice depends on whether you prioritize permeability for breathability or robustness for protection in demanding environments.

Microporous rubber vs Dense rubber Infographic

libmatt.com

libmatt.com