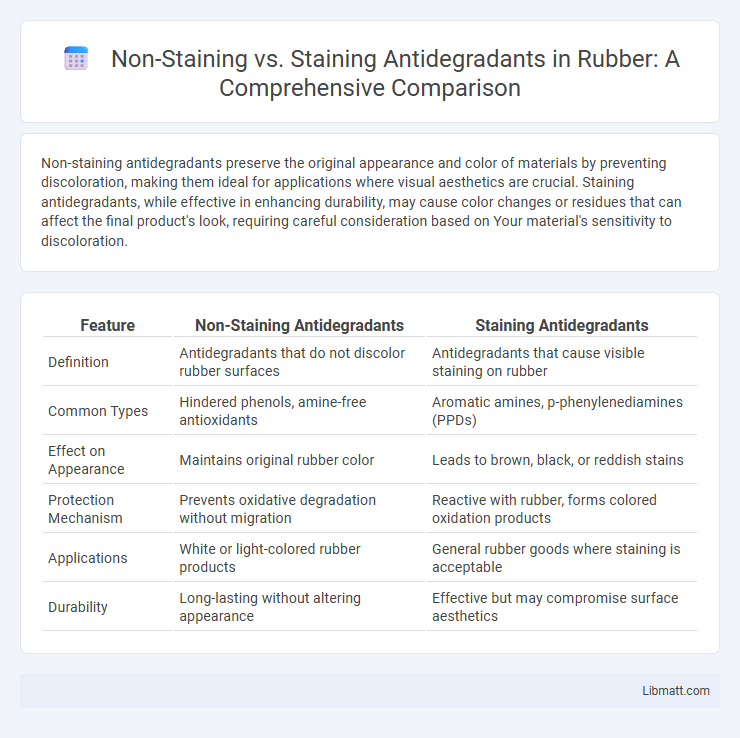

Non-staining antidegradants preserve the original appearance and color of materials by preventing discoloration, making them ideal for applications where visual aesthetics are crucial. Staining antidegradants, while effective in enhancing durability, may cause color changes or residues that can affect the final product's look, requiring careful consideration based on Your material's sensitivity to discoloration.

Table of Comparison

| Feature | Non-Staining Antidegradants | Staining Antidegradants |

|---|---|---|

| Definition | Antidegradants that do not discolor rubber surfaces | Antidegradants that cause visible staining on rubber |

| Common Types | Hindered phenols, amine-free antioxidants | Aromatic amines, p-phenylenediamines (PPDs) |

| Effect on Appearance | Maintains original rubber color | Leads to brown, black, or reddish stains |

| Protection Mechanism | Prevents oxidative degradation without migration | Reactive with rubber, forms colored oxidation products |

| Applications | White or light-colored rubber products | General rubber goods where staining is acceptable |

| Durability | Long-lasting without altering appearance | Effective but may compromise surface aesthetics |

Introduction to Antidegradants in Rubber Compounds

Antidegradants in rubber compounds are essential additives designed to protect polymers from oxidative, thermal, and ozone-induced degradation, thereby extending the material's service life. Non-staining antidegradants, such as certain amine and phenolic types, prevent discoloration and maintain the rubber's aesthetic properties, making them ideal for visible or light-colored applications. In contrast, staining antidegradants, often containing specific chemical groups like diphenylamine derivatives, provide robust protection but can cause darkening or staining on the rubber surface.

What Are Non-Staining Antidegradants?

Non-staining antidegradants are specialized additives used in rubber and polymer materials to prevent degradation without causing discoloration or staining of the product. These compounds protect against oxidative, thermal, and ozone-induced damage while maintaining the original appearance and physical properties of the material. Their application is crucial in industries requiring clear, aesthetically consistent products, such as automotive seals, medical devices, and transparent packaging.

Overview of Staining Antidegradants

Staining antidegradants are chemical additives used in rubber and polymer industries to enhance material durability by preventing degradation caused by oxygen, heat, and light. These compounds are prone to discoloring the polymer matrix, often resulting in yellowing or darkening of the material over time. Common examples include aminic and phenolic antioxidants that migrate to the surface, leading to visible stains that can affect the aesthetic quality of the final product.

Key Differences: Non-Staining vs Staining Antidegradants

Non-staining antidegradants protect materials without leaving visible residues, making them ideal for applications where appearance is critical, such as in rubber and plastic products. Staining antidegradants, on the other hand, may cause discoloration or surface alterations but offer robust protection against oxidative and thermal degradation in heavy-duty environments. Your choice between non-staining and staining antidegradants depends on the balance between aesthetic requirements and the level of protection needed for long-term material durability.

Chemical Mechanisms and Protective Actions

Non-staining antidegradants work by neutralizing reactive oxygen species or free radicals through chemical reactions that do not form colored complexes, preserving the original appearance of materials. Staining antidegradants often form metal chelates or oxidation products that cause discoloration or darkening, a result of their interaction with material components and environmental factors like light or heat. Understanding these chemical mechanisms allows you to select the most suitable antidegradant, balancing protection efficacy with aesthetic preservation.

Impact on Rubber Physical Properties

Non-staining antidegradants preserve the original appearance of rubber by preventing discoloration while maintaining essential physical properties such as tensile strength and elasticity. Staining antidegradants, although effective in protecting rubber from oxidative degradation, often cause visible discoloration, which may indicate chemical interactions that can alter the rubber's flexibility and abrasion resistance. Selecting non-staining antidegradants is critical for applications requiring both aesthetic appeal and durability in rubber products.

Applications and Suitability for Various Industries

Non-staining antidegradants are preferred in food packaging, textiles, and pharmaceuticals due to their compatibility with sensitive materials and non-discoloring properties. Staining antidegradants, often used in rubber and automotive industries, provide robust protection but may cause color changes that are acceptable in industrial settings. Selection depends on industry-specific requirements for visual appearance and long-term material stability.

Advantages and Limitations of Non-Staining Antidegradants

Non-staining antidegradants are preferred in polymer stabilization due to their ability to protect materials without causing discoloration, maintaining the aesthetic integrity of your products. Their advantages include enhanced compatibility with color-sensitive applications and prevention of surface defects, while limitations involve potentially lower efficiency in extreme degradation conditions compared to staining counterparts. Selecting the right non-staining antidegradant ensures optimal balance between protection and visual preservation for long-lasting polymer performance.

Environmental and Safety Considerations

Non-staining antidegradants are preferred in environmentally sensitive applications due to their low toxicity and minimal impact on surrounding ecosystems, making them safer for use in consumer products and food packaging. Staining antidegradants, while effective in protecting materials from degradation, often contain heavy metals or chemicals that can leach into soil and water, posing risks to wildlife and human health. Rigorous environmental regulations increasingly favor non-staining options to reduce hazardous waste and promote sustainable manufacturing practices.

Selecting the Right Antidegradant for Rubber Products

Selecting the right antidegradant for rubber products depends on whether you prioritize preserving the rubber's appearance or maximizing its longevity. Non-staining antidegradants prevent discoloration and maintain the original color of your rubber, making them ideal for aesthetic-sensitive applications. Staining antidegradants may cause color changes but offer superior protection against ozone, heat, and UV degradation, enhancing the durability of rubber in demanding environments.

Non-staining vs Staining antidegradants Infographic

libmatt.com

libmatt.com