Sintered rubber offers enhanced durability and resistance to wear due to its unique processing method, making it ideal for high-performance applications. Your choice between sintered and molded rubber should consider factors like strength, flexibility, and production cost for optimal results.

Table of Comparison

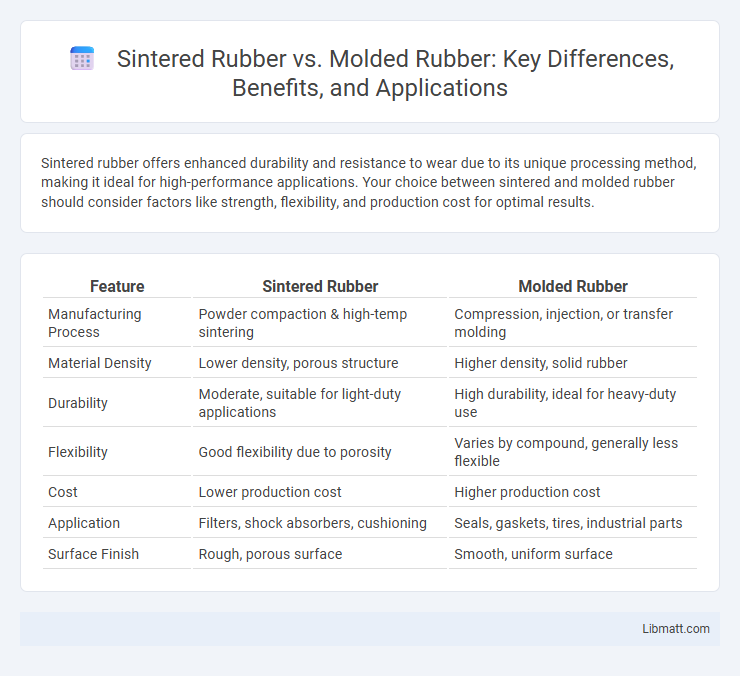

| Feature | Sintered Rubber | Molded Rubber |

|---|---|---|

| Manufacturing Process | Powder compaction & high-temp sintering | Compression, injection, or transfer molding |

| Material Density | Lower density, porous structure | Higher density, solid rubber |

| Durability | Moderate, suitable for light-duty applications | High durability, ideal for heavy-duty use |

| Flexibility | Good flexibility due to porosity | Varies by compound, generally less flexible |

| Cost | Lower production cost | Higher production cost |

| Application | Filters, shock absorbers, cushioning | Seals, gaskets, tires, industrial parts |

| Surface Finish | Rough, porous surface | Smooth, uniform surface |

Introduction to Sintered Rubber and Molded Rubber

Sintered rubber is formed by heating rubber particles below their melting point until they fuse together, creating a dense, durable material ideal for high-wear applications. Molded rubber involves shaping raw rubber compounds into specific forms using molds under heat and pressure, allowing for precise and complex designs. Understanding the differences between these processes helps you select the best material for performance and manufacturing efficiency.

Manufacturing Processes: Sintered vs Molded Rubber

Sintered rubber is produced by heating rubber powder below its melting point until particles fuse, creating a dense, uniform material with enhanced mechanical properties. Molded rubber involves injecting or compressing raw rubber into a shaped mold, then vulcanizing it under heat and pressure to form flexible, precise parts. The sintering process yields components with superior wear resistance, while molding offers greater design versatility and faster production cycles.

Material Composition and Properties

Sintered rubber is produced through a powder metallurgy process, combining fine rubber particles under heat and pressure without melting, resulting in a porous, highly elastic material ideal for shock absorption and flexibility. Molded rubber is formed by injecting or compressing raw rubber compounds into molds, allowing precise control over density and hardness through additives and curing agents, producing durable, abrasion-resistant products with uniform properties. The choice between sintered and molded rubber depends on application-specific requirements, including porosity, tensile strength, and resistance to environmental factors.

Performance and Durability Comparison

Sintered rubber offers superior wear resistance and enhanced durability due to its porous structure, making it ideal for applications requiring high friction and thermal stability. Molded rubber provides greater flexibility and precise shaping capabilities, which contribute to better performance in dynamic load conditions and complex geometries. Both materials exhibit strong mechanical properties, but sintered rubber generally outperforms molded rubber in abrasion resistance, while molded rubber excels in impact absorption and elasticity.

Cost Differences and Economic Considerations

Sintered rubber typically incurs higher initial production costs due to its complex manufacturing process involving powder compaction and heat treatment, making it suitable for specialized applications requiring enhanced material properties. Molded rubber, conversely, offers cost-effective mass production through injection or compression molding, reducing unit costs and enabling efficient scalability for your projects. Evaluating long-term durability and performance alongside upfront expenses helps determine the most economical choice for your specific application needs.

Applications and Industry Uses

Sintered rubber offers superior durability and is commonly used in high-performance applications such as automotive seals, industrial gaskets, and specialized machinery components due to its enhanced resistance to heat and wear. Molded rubber is versatile and widely employed across industries including automotive, aerospace, and consumer goods for manufacturing flexible, complex shapes like O-rings, bumpers, and grips. Choosing between sintered and molded rubber depends on Your specific requirements for strength, flexibility, and environmental resistance in targeted industrial applications.

Environmental Impact and Sustainability

Sintered rubber typically uses less energy during production compared to molded rubber, resulting in a lower carbon footprint and reduced greenhouse gas emissions, enhancing its environmental sustainability. Molded rubber often involves higher material wastage and energy consumption due to its complex shaping processes, increasing its environmental impact. Choosing sintered rubber supports circular economy goals as it often incorporates recycled materials and offers better potential for recycling after use.

Customization and Design Flexibility

Sintered rubber offers high customization through its ability to form complex shapes with precise detail by fusing powdered rubber under heat and pressure, ideal for intricate designs and tailored mechanical properties. Molded rubber provides extensive design flexibility via injection or compression molding processes, allowing for the creation of varied shapes and sizes with consistent quality and reduced material waste. Both methods enable customization, but sintered rubber excels in microstructural control, while molded rubber is preferred for rapid production of diverse, larger parts.

Advantages and Disadvantages Summary

Sintered rubber offers superior wear resistance and durability due to its porous structure, making it ideal for high-friction applications, but it can be more expensive and less flexible than molded rubber. Molded rubber provides excellent versatility and cost-effectiveness with greater flexibility and intricate design capabilities, though it may lack the longevity and abrasion resistance of sintered rubber. Your choice depends on balancing durability needs with design complexity and budget constraints.

Choosing the Right Rubber Technology for Your Needs

Sintered rubber offers enhanced durability and resistance to chemicals through a heat and pressure fusion process, making it ideal for heavy-duty industrial applications. Molded rubber allows for precise shaping with varied compounds, providing flexibility in design and quick production for customized parts. Selecting between sintered and molded rubber depends on the required mechanical properties, production volume, and environmental conditions of the application.

Sintered Rubber vs Molded Rubber Infographic

libmatt.com

libmatt.com