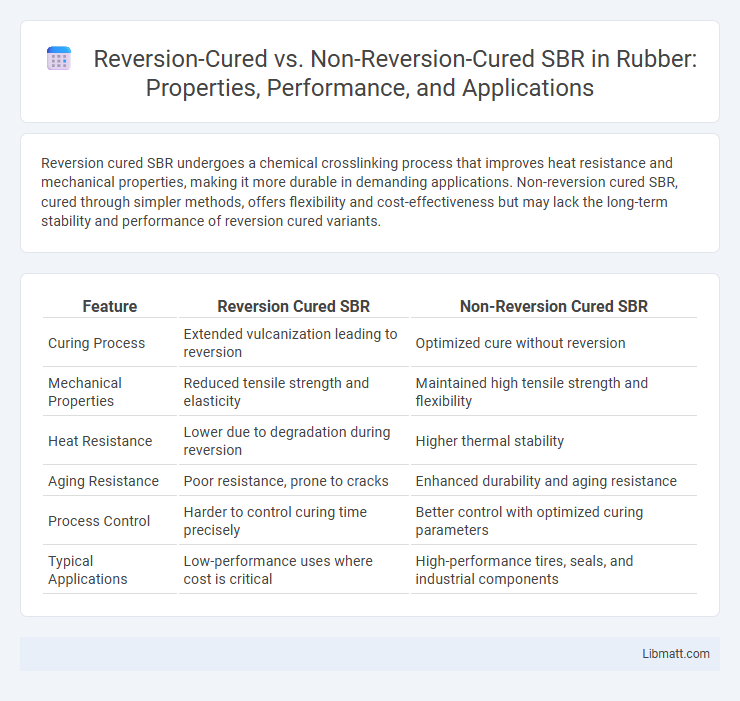

Reversion cured SBR undergoes a chemical crosslinking process that improves heat resistance and mechanical properties, making it more durable in demanding applications. Non-reversion cured SBR, cured through simpler methods, offers flexibility and cost-effectiveness but may lack the long-term stability and performance of reversion cured variants.

Table of Comparison

| Feature | Reversion Cured SBR | Non-Reversion Cured SBR |

|---|---|---|

| Curing Process | Extended vulcanization leading to reversion | Optimized cure without reversion |

| Mechanical Properties | Reduced tensile strength and elasticity | Maintained high tensile strength and flexibility |

| Heat Resistance | Lower due to degradation during reversion | Higher thermal stability |

| Aging Resistance | Poor resistance, prone to cracks | Enhanced durability and aging resistance |

| Process Control | Harder to control curing time precisely | Better control with optimized curing parameters |

| Typical Applications | Low-performance uses where cost is critical | High-performance tires, seals, and industrial components |

Introduction to SBR: Overview and Importance

Styrene-Butadiene Rubber (SBR) is a synthetic polymer widely used for its excellent abrasion resistance and aging stability in tire manufacturing and industrial applications. Reversion cured SBR undergoes a controlled curing process that minimizes polymer chain degradation, resulting in improved mechanical properties and durability. Non-reversion cured SBR typically experiences degradation during vulcanization, leading to reduced performance and shorter lifespan in end-use products.

What is Reversion Curing in SBR?

Reversion curing in Styrene-Butadiene Rubber (SBR) refers to the degradation process where the polymer's crosslinked network breaks down due to excessive heat or prolonged vulcanization, leading to reduced mechanical properties. Reversion cured SBR undergoes partial network breakdown, resulting in lower tensile strength and elasticity compared to non-reversion cured SBR, which maintains optimal curing conditions and stable crosslink density. Controlling curing temperature and time is critical to prevent reversion and ensure consistent performance in SBR applications such as tires and industrial rubber goods.

Understanding Non-Reversion Cured SBR

Non-reversion cured SBR (Styrene-Butadiene Rubber) undergoes a curing process that prevents the polymer from reverting to its uncured state under heat or stress, enhancing thermal stability and durability. Unlike reversion cured SBR, which can lose cross-link density when exposed to high temperatures, non-reversion cured SBR maintains structural integrity and mechanical properties over extended service conditions. This stability makes non-reversion cured SBR ideal for applications requiring long-term resistance to heat aging and dynamic stress in automotive tires and industrial products.

Key Differences: Reversion vs Non-Reversion Cured SBR

Reversion cured SBR (Styrene-Butadiene Rubber) undergoes a reversion process that partially breaks and reforms crosslinks, enhancing flexibility and reducing brittleness, whereas non-reversion cured SBR maintains stable crosslink structures resulting in higher tensile strength and improved heat resistance. The reversion curing method targets a balance between elasticity and durability, making it ideal for applications demanding dynamic performance and resilience. Non-reversion cured SBR is preferred for static applications requiring consistent mechanical properties and prolonged aging stability under thermal stress.

Processing Conditions for Reversion and Non-Reversion SBR

Reversion cured SBR requires precise temperature control, typically between 150-190degC, to prevent polymer degradation and maintain optimal molecular properties during vulcanization. Non-reversion cured SBR allows for a broader processing window, often cured below 160degC, reducing risks of scorch and ensuring consistent cross-link density for improved mechanical performance. Your choice of processing conditions directly impacts the balance between cure efficiency and product durability in SBR applications.

Physical and Mechanical Properties Comparison

Reversion cured SBR exhibits superior physical properties compared to non-reversion cured SBR, including enhanced thermal stability and resistance to oxidation, resulting in less degradation during service. Mechanically, reversion cured SBR maintains higher tensile strength, elongation at break, and improved abrasion resistance, which contributes to extended durability in dynamic applications. Non-reversion cured SBR typically shows reduced elasticity and faster aging effects, compromising overall performance under cyclic stress conditions.

Heat Aging and Performance Stability

Reversion cured Styrene-Butadiene Rubber (SBR) exhibits superior heat aging resistance due to its enhanced crosslink density, resulting in improved performance stability under prolonged thermal exposure. Non-reversion cured SBR tends to suffer from chain scission and loss of mechanical properties when subjected to high heat, leading to reduced durability. Consequently, reversion cured SBR maintains tensile strength, elasticity, and abrasion resistance more effectively in applications demanding long-term thermal stability.

Applications of Reversion Cured SBR

Reversion cured SBR exhibits superior abrasion resistance and tensile strength, making it ideal for high-performance tire treads and automotive components. Its enhanced durability under dynamic stress conditions suits industrial belts and conveyor systems requiring prolonged operational lifespan. These applications benefit from the polymer's optimized crosslinking density, which improves elasticity and wear resistance in demanding environments.

Applications of Non-Reversion Cured SBR

Non-reversion cured SBR (styrene-butadiene rubber) is primarily used in applications requiring durable and heat-resistant materials, such as tire treads, conveyor belts, and shoe soles. This type of SBR provides better resistance to reversion, which enhances the longevity and performance of rubber products exposed to high temperatures. Its superior thermal stability makes it ideal for automotive and industrial uses where consistent physical properties are critical.

Selecting the Right SBR Curing System

Selecting the right SBR curing system depends on application-specific performance requirements, where reversion cured SBR offers enhanced heat resistance and durability due to its stable cross-linking structure. Non-reversion cured SBR, while more cost-effective, may experience degradation under prolonged thermal stress, limiting its use in high-temperature environments. Evaluating factors such as operational temperature, mechanical properties, and longevity is essential for optimizing the curing process and ensuring product reliability.

Reversion cured vs Non-reversion cured SBR Infographic

libmatt.com

libmatt.com