Black masterbatch primarily contains carbon black pigments, providing superior UV protection and opacity for your plastic products, while color masterbatch offers a wide range of vibrant pigments to achieve specific hues. Both enhance the appearance and performance of plastics, but black masterbatch is ideal for applications requiring durability and UV resistance, whereas color masterbatch focuses on aesthetic customization.

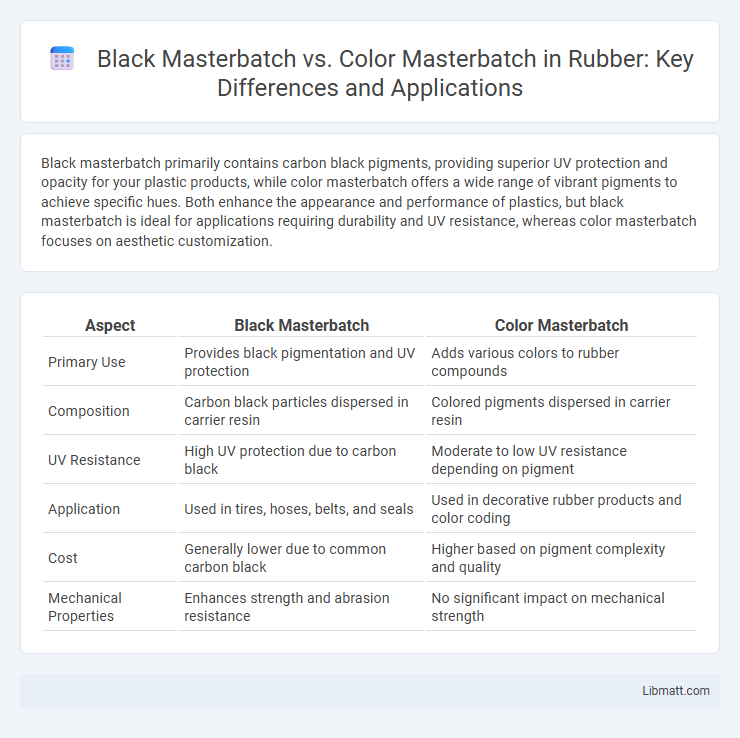

Table of Comparison

| Aspect | Black Masterbatch | Color Masterbatch |

|---|---|---|

| Primary Use | Provides black pigmentation and UV protection | Adds various colors to rubber compounds |

| Composition | Carbon black particles dispersed in carrier resin | Colored pigments dispersed in carrier resin |

| UV Resistance | High UV protection due to carbon black | Moderate to low UV resistance depending on pigment |

| Application | Used in tires, hoses, belts, and seals | Used in decorative rubber products and color coding |

| Cost | Generally lower due to common carbon black | Higher based on pigment complexity and quality |

| Mechanical Properties | Enhances strength and abrasion resistance | No significant impact on mechanical strength |

Introduction to Masterbatches

Masterbatches are concentrated mixtures of pigments and additives encapsulated during a heat process into a carrier resin, used to color or enhance plastics. Black masterbatch primarily contains carbon black or other black pigments, providing deep, consistent black coloration and UV protection for plastic products. Color masterbatch encompasses a wide range of pigments offering vibrant hues and special effects, allowing you to customize your plastic materials with precise color control and improved aesthetic appeal.

What is Black Masterbatch?

Black Masterbatch is a concentrated mixture of carbon black pigment and carrier resin used to impart deep black coloration to plastic products. It enhances UV resistance, improves opacity, and provides consistent color dispersion in polymers like polyethylene, polypropylene, and PVC. This masterbatch is widely used in automotive parts, packaging, and consumer goods manufacturing to achieve durability and uniform black hues.

What is Color Masterbatch?

Color masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin used to impart color to plastic products during manufacturing. It offers precise color customization, consistent pigmentation, and excellent dispersion properties, making it ideal for various polymer applications. Unlike black masterbatch, which is specifically designed for black or dark-colored plastics, color masterbatch covers a broad spectrum of vibrant hues for diverse aesthetic requirements.

Key Components of Black and Color Masterbatch

Black masterbatch primarily contains carbon black as its key component, ensuring high pigmentation and UV resistance for enhanced durability in plastic products. Color masterbatch incorporates organic or inorganic pigments tailored to achieve specific hues, with additives to improve dispersion and color stability. Both types include a carrier resin compatible with the base polymer, facilitating uniform distribution of pigments during the manufacturing process.

Production Process Comparison

Black masterbatch production involves the dispersion of carbon black, a cost-effective pigment, into a polymer carrier resin through high-shear mixing and extrusion, providing superior UV protection and opacity. Color masterbatch production requires the incorporation of organic and inorganic pigments or dyes evenly mixed within a polymer carrier using similar compounding techniques, but with more complex color calibration and compatibility testing to achieve specific hues and colorfastness. The key differentiation lies in the pigment type and formulation complexity, where black masterbatch emphasizes durability and masking properties, while color masterbatch prioritizes color accuracy and aesthetic versatility.

Performance and Application Differences

Black masterbatch offers superior UV resistance, excellent carbon black dispersion, and enhanced masking properties, making it ideal for outdoor applications and products requiring high durability. Color masterbatch provides a wide range of vibrant hues with precise color consistency, suitable for aesthetic-focused applications such as packaging and consumer goods. Your choice depends on performance needs; black masterbatch excels in protection and longevity, while color masterbatch prioritizes visual appeal and customization.

Cost Analysis: Black vs Color Masterbatch

Black masterbatch generally offers a cost advantage over color masterbatch due to the widespread availability and lower price of carbon black pigment compared to specialized color pigments. The manufacturing process for black masterbatch involves fewer additives and simpler formulation, resulting in reduced production costs. You can optimize your budget by selecting black masterbatch for applications where standard coloration meets design needs, while color masterbatch typically demands higher investment for custom hues and consistent color matching.

Advantages of Using Black Masterbatch

Black masterbatch offers superior UV resistance and excellent color consistency, making it ideal for outdoor applications and products requiring long-lasting pigmentation. It improves processing efficiency by enhancing dispersion and reducing contamination, resulting in higher-quality plastic products. Your choice of black masterbatch ensures better opacity and protection against light degradation compared to color masterbatch, which is more suited for vibrant, customized hues.

Benefits of Using Color Masterbatch

Color masterbatch offers enhanced color consistency and vibrancy across plastic products, ensuring precise shade matching for brand identity. It improves aesthetic appeal without affecting the polymer's physical properties, enabling customization in various applications such as packaging, automotive parts, and consumer goods. Unlike black masterbatch, which primarily provides opacity and UV resistance, color masterbatch allows for a broad spectrum of hues and effects that elevate product differentiation and market competitiveness.

Choosing the Right Masterbatch for Your Application

Selecting the right masterbatch for your application depends on the desired color intensity and functional properties. Black masterbatch offers superior UV resistance and cost-effective opacity, making it ideal for outdoor or protective products, while color masterbatch provides vibrant hues and customizable shades for aesthetic-focused applications. Your choice should consider the material compatibility, processing conditions, and end-use requirements to ensure optimal performance and appearance.

Black Masterbatch vs Color Masterbatch Infographic

libmatt.com

libmatt.com