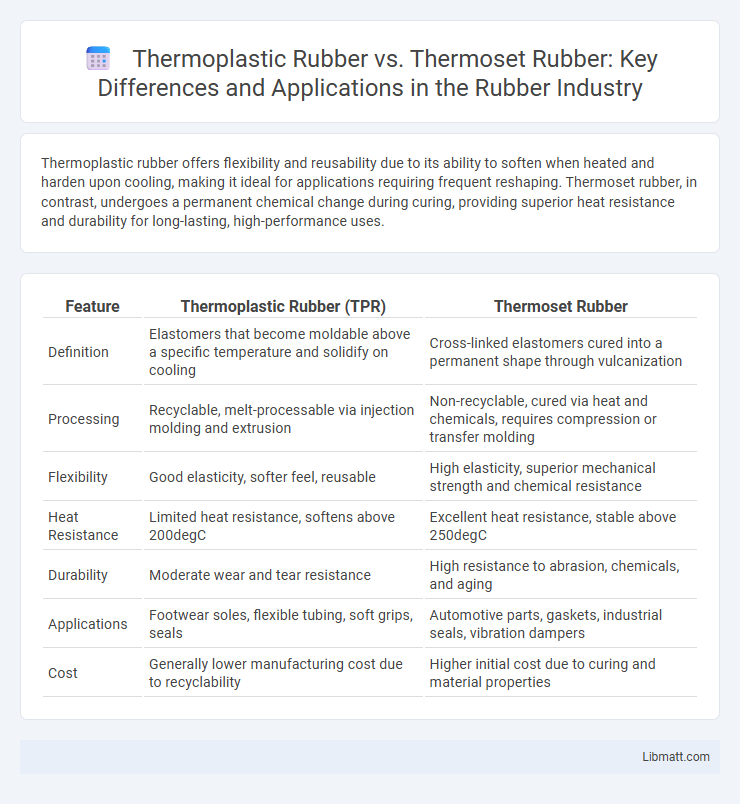

Thermoplastic rubber offers flexibility and reusability due to its ability to soften when heated and harden upon cooling, making it ideal for applications requiring frequent reshaping. Thermoset rubber, in contrast, undergoes a permanent chemical change during curing, providing superior heat resistance and durability for long-lasting, high-performance uses.

Table of Comparison

| Feature | Thermoplastic Rubber (TPR) | Thermoset Rubber |

|---|---|---|

| Definition | Elastomers that become moldable above a specific temperature and solidify on cooling | Cross-linked elastomers cured into a permanent shape through vulcanization |

| Processing | Recyclable, melt-processable via injection molding and extrusion | Non-recyclable, cured via heat and chemicals, requires compression or transfer molding |

| Flexibility | Good elasticity, softer feel, reusable | High elasticity, superior mechanical strength and chemical resistance |

| Heat Resistance | Limited heat resistance, softens above 200degC | Excellent heat resistance, stable above 250degC |

| Durability | Moderate wear and tear resistance | High resistance to abrasion, chemicals, and aging |

| Applications | Footwear soles, flexible tubing, soft grips, seals | Automotive parts, gaskets, industrial seals, vibration dampers |

| Cost | Generally lower manufacturing cost due to recyclability | Higher initial cost due to curing and material properties |

Introduction to Thermoplastic Rubber and Thermoset Rubber

Thermoplastic rubber (TPR) combines the properties of rubber and plastic, offering flexibility, durability, and the ability to be melted and reshaped multiple times. Thermoset rubber, once cured through heat or chemical processes, forms a rigid, permanently cross-linked structure that cannot be remelted or reshaped. Understanding these fundamental differences helps you choose the right material for applications requiring either recyclability or superior heat resistance.

Chemical Structure and Composition Differences

Thermoplastic rubber consists of linear or slightly branched polymers that soften when heated due to physical crosslinks, allowing it to be reshaped repeatedly. Thermoset rubber features a chemically crosslinked three-dimensional network formed during curing, making it rigid and heat-resistant without melting upon reheating. Your choice between these materials depends on the required flexibility, durability, and thermal stability dictated by their distinct chemical structures and compositions.

Manufacturing Processes Compared

Thermoplastic rubber (TPR) manufacturing involves melting and molding processes such as injection molding or extrusion, allowing repeated reheating and reshaping without chemical changes. Thermoset rubber production relies on vulcanization, a chemical curing process that creates irreversible cross-linked polymers, resulting in a rigid, heat-resistant final product. The fundamental difference lies in TPR's ability to be remolded multiple times, while thermoset rubber solidifies permanently after curing.

Mechanical Properties: Flexibility and Strength

Thermoplastic rubber offers superior flexibility due to its ability to be reshaped with heat, making it ideal for applications requiring repeated bending and stretching without permanent deformation. Thermoset rubber, on the other hand, provides higher strength and durability as it undergoes a curing process that creates a rigid, cross-linked structure resistant to wear and tear. Your choice depends on whether flexibility or long-lasting strength is more critical for the mechanical performance of your product.

Thermal Stability and Heat Resistance

Thermoplastic rubber exhibits moderate thermal stability, typically withstanding temperatures up to 230degC before softening, making it suitable for applications requiring flexibility and repeated heating cycles. Thermoset rubber offers superior heat resistance due to its cross-linked molecular structure, maintaining structural integrity at temperatures exceeding 300degC and providing enhanced performance in high-heat environments. The permanent bonds in thermoset rubber prevent melting under heat, contrasting with the reversible softening characteristic of thermoplastic rubber.

Recyclability and Environmental Impact

Thermoplastic rubber (TPR) offers superior recyclability due to its ability to be melted and reprocessed multiple times without significant degradation, reducing waste and environmental impact. In contrast, thermoset rubber undergoes irreversible curing, making recycling difficult and often resulting in disposal through landfilling or incineration, which contributes to environmental pollution. The lower recyclability of thermoset rubber leads to higher ecological footprint, whereas TPR supports sustainable manufacturing and waste minimization.

Common Applications and Industry Uses

Thermoplastic rubber is commonly used in automotive parts, medical devices, and consumer electronics due to its flexibility, recyclability, and ease of processing. Thermoset rubber finds applications in high-performance seals, gaskets, and electrical insulation, where durability and heat resistance are critical. Understanding the specific requirements of your industry helps determine whether thermoplastic or thermoset rubber is the optimal material choice.

Cost and Economic Considerations

Thermoplastic rubber generally offers lower production costs due to its reusability and efficient manufacturing processes, making it ideal for applications requiring frequent molding or recycling. Thermoset rubber involves higher initial tooling expenses and longer curing times, which can increase production costs but provides superior durability and heat resistance, justifying the investment in long-term performance scenarios. Understanding these economic considerations helps you select the most cost-effective material based on your product lifecycle and budget constraints.

Performance in Extreme Conditions

Thermoplastic rubber maintains flexibility and impact resistance at low temperatures, while thermoset rubber excels in high-heat and chemical resistance due to its cross-linked structure. Your choice depends on the specific environmental stresses, as thermoset rubber offers superior durability in prolonged extreme heat, whereas thermoplastic rubber performs better under repeated flexing and cold conditions. Understanding these performance differences ensures optimal material selection for applications exposed to harsh temperatures or chemical exposure.

Selecting the Right Rubber for Your Application

Selecting the right rubber for your application depends on factors such as flexibility, temperature resistance, and durability requirements. Thermoplastic rubber offers excellent elasticity and can be reshaped multiple times, making it ideal for applications requiring frequent deformation and recycling. Thermoset rubber provides superior heat resistance and mechanical strength, suitable for high-stress environments where durability and permanent shape retention are critical.

Thermoplastic Rubber vs Thermoset Rubber Infographic

libmatt.com

libmatt.com