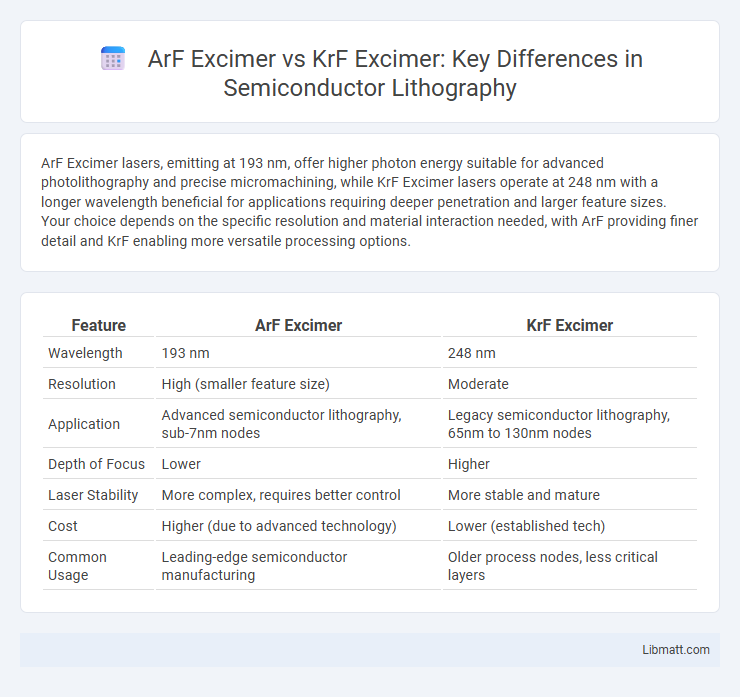

ArF Excimer lasers, emitting at 193 nm, offer higher photon energy suitable for advanced photolithography and precise micromachining, while KrF Excimer lasers operate at 248 nm with a longer wavelength beneficial for applications requiring deeper penetration and larger feature sizes. Your choice depends on the specific resolution and material interaction needed, with ArF providing finer detail and KrF enabling more versatile processing options.

Table of Comparison

| Feature | ArF Excimer | KrF Excimer |

|---|---|---|

| Wavelength | 193 nm | 248 nm |

| Resolution | High (smaller feature size) | Moderate |

| Application | Advanced semiconductor lithography, sub-7nm nodes |

Legacy semiconductor lithography, 65nm to 130nm nodes |

| Depth of Focus | Lower | Higher |

| Laser Stability | More complex, requires better control | More stable and mature |

| Cost | Higher (due to advanced technology) | Lower (established tech) |

| Common Usage | Leading-edge semiconductor manufacturing | Older process nodes, less critical layers |

Overview of Excimer Lasers

ArF excimer lasers emit ultraviolet light at a wavelength of 193 nm, while KrF excimer lasers operate at 248 nm, making both ideal for photolithography and micromachining applications due to their high photon energy and short pulses. ArF lasers provide higher resolution in semiconductor manufacturing, enabling finer patterning compared to KrF lasers, which offer deeper penetration in materials. Your choice between ArF and KrF excimer lasers depends on the required precision and material interaction needed for specific industrial or research purposes.

What is ArF Excimer?

ArF Excimer lasers emit ultraviolet light at a wavelength of 193 nm, making them essential for high-precision photolithography in semiconductor manufacturing. Unlike KrF Excimer lasers operating at 248 nm, ArF lasers provide finer resolution crucial for producing smaller microchip features. You can leverage ArF Excimer technology to achieve superior patterning accuracy in advanced microelectronic device fabrication.

What is KrF Excimer?

KrF excimer lasers utilize a krypton-fluorine gas mixture to generate ultraviolet light at a wavelength of 248 nm, commonly used in photolithography and micromachining. These lasers are valued for their high pulse energy and short wavelength, enabling precise material processing with minimal thermal damage. Compared to ArF excimers, which operate at 193 nm, KrF lasers offer deeper penetration and are often preferred for applications requiring robust etching and patterning on semiconductor wafers.

Key Differences: ArF vs KrF Excimer

ArF Excimer lasers emit ultraviolet light at a wavelength of 193 nm, while KrF Excimer lasers operate at 248 nm, making ArF more suitable for applications requiring higher resolution such as advanced photolithography in semiconductor manufacturing. ArF lasers produce shorter wavelengths, resulting in finer feature patterning and better critical dimension control compared to KrF lasers. The difference in photon energy between ArF and KrF excimer lasers directly influences their absorption characteristics and process precision in microfabrication technologies.

Wavelength Comparison: ArF vs KrF

ArF excimer lasers emit ultraviolet light at a wavelength of 193 nm, while KrF excimer lasers operate at 248 nm, making the ArF wavelength shorter and more suitable for high-resolution photolithography. The shorter 193 nm wavelength of ArF allows for finer patterning in semiconductor manufacturing due to its higher photon energy and reduced diffraction limits compared to the 248 nm wavelength of KrF. This wavelength difference is critical in advancing semiconductor node shrinkage, with ArF enabling more precise and smaller feature sizes than KrF excimer lasers.

Applications of ArF Excimer Lasers

ArF excimer lasers, operating at a wavelength of 193 nm, are widely used in semiconductor photolithography due to their ability to achieve fine patterning essential for advanced microchip fabrication. These lasers also play a critical role in LASIK eye surgery, providing precise corneal ablation with minimal thermal damage. Your precision manufacturing and medical procedures benefit significantly from the superior resolution and control offered by ArF excimer technology compared to KrF excimer lasers.

Applications of KrF Excimer Lasers

KrF excimer lasers, with a wavelength of 248 nm, are widely used in semiconductor photolithography due to their precise patterning capabilities for microchip fabrication. Their high-energy UV pulses enable micromachining and surface modification applications, including eye surgery (LASIK) and micromaterial processing. Your choice of KrF excimer laser ensures excellent resolution and efficiency in industrial and medical settings where ultraviolet laser technology is critical.

Performance and Efficiency Analysis

ArF Excimer lasers operate predominantly at a 193 nm wavelength, offering superior resolution and higher precision in photolithography processes compared to KrF Excimer lasers, which emit at 248 nm. Your choice affects efficiency: ArF lasers exhibit higher photon energy, enabling finer feature patterns but typically consume more power and require advanced cooling systems, whereas KrF lasers provide a cost-effective solution with slightly lower precision and better energy efficiency. Performance-wise, ArF excels in semiconductor manufacturing demanding sub-20 nm nodes, while KrF remains effective for applications where moderate resolution suffices at lower operational costs.

Material Compatibility and Limitations

ArF excimer lasers emit at 193 nm, enabling high precision in photolithography but require materials with exceptional UV transparency such as fused silica or calcium fluoride to avoid degradation. KrF excimer lasers operate at 248 nm, offering broader material compatibility, including standard optical glasses and photoresists, but with slightly lower resolution capabilities. Your choice depends on balancing material durability and process requirements, with ArF favored for fine feature patterning and KrF suitable for more robust or cost-effective applications.

Choosing Between ArF and KrF Excimer Lasers

ArF excimer lasers emit ultraviolet light at 193 nm, offering higher resolution and finer feature printing, making them ideal for advanced semiconductor lithography. KrF excimer lasers operate at 248 nm, providing a balance between cost-efficiency and performance, suitable for less demanding microfabrication processes. Selection between ArF and KrF excimer lasers depends on precision requirements, budget constraints, and desired process throughput in photolithography applications.

ArF Excimer vs KrF Excimer Infographic

libmatt.com

libmatt.com