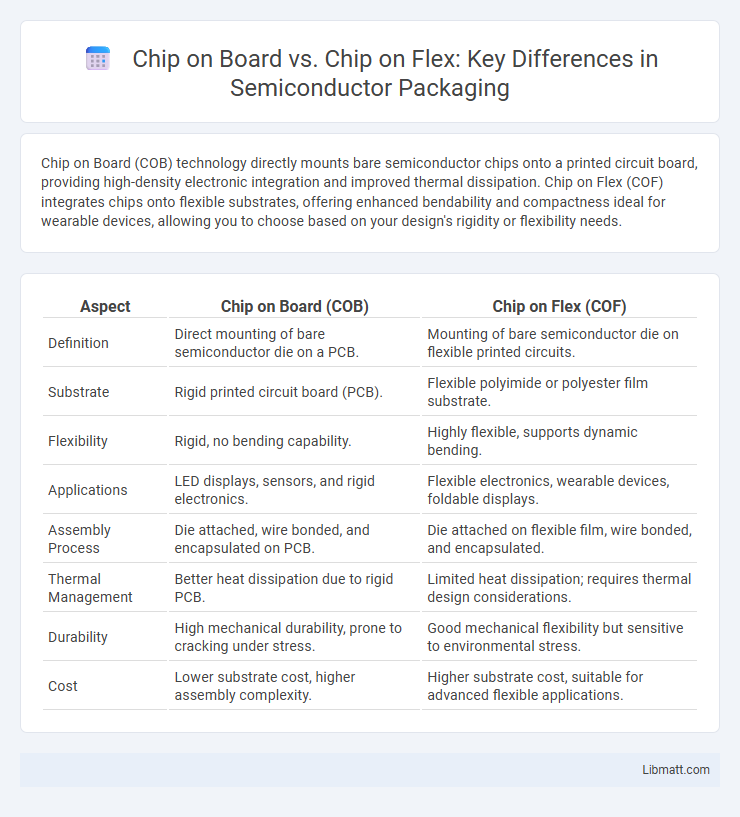

Chip on Board (COB) technology directly mounts bare semiconductor chips onto a printed circuit board, providing high-density electronic integration and improved thermal dissipation. Chip on Flex (COF) integrates chips onto flexible substrates, offering enhanced bendability and compactness ideal for wearable devices, allowing you to choose based on your design's rigidity or flexibility needs.

Table of Comparison

| Aspect | Chip on Board (COB) | Chip on Flex (COF) |

|---|---|---|

| Definition | Direct mounting of bare semiconductor die on a PCB. | Mounting of bare semiconductor die on flexible printed circuits. |

| Substrate | Rigid printed circuit board (PCB). | Flexible polyimide or polyester film substrate. |

| Flexibility | Rigid, no bending capability. | Highly flexible, supports dynamic bending. |

| Applications | LED displays, sensors, and rigid electronics. | Flexible electronics, wearable devices, foldable displays. |

| Assembly Process | Die attached, wire bonded, and encapsulated on PCB. | Die attached on flexible film, wire bonded, and encapsulated. |

| Thermal Management | Better heat dissipation due to rigid PCB. | Limited heat dissipation; requires thermal design considerations. |

| Durability | High mechanical durability, prone to cracking under stress. | Good mechanical flexibility but sensitive to environmental stress. |

| Cost | Lower substrate cost, higher assembly complexity. | Higher substrate cost, suitable for advanced flexible applications. |

Introduction to Chip on Board (COB) and Chip on Flex (COF) Technologies

Chip on Board (COB) technology involves directly mounting bare semiconductor chips onto a printed circuit board, offering enhanced electrical performance and thermal management for compact electronic devices. Chip on Flex (COF) technology attaches chips to flexible substrates, enabling lightweight, bendable, and space-saving designs ideal for wearable gadgets and flexible displays. Your choice between COB and COF depends on the application's size constraints, flexibility requirements, and thermal considerations.

Core Principles of COB and COF Packaging

Chip on Board (COB) packaging involves directly mounting semiconductor chips onto a printed circuit board (PCB) and encasing them with epoxy, enhancing thermal performance and reducing space. Chip on Flex (COF) packaging uses flexible printed circuits to connect chips, providing superior flexibility and suitability for curved or dynamic surfaces. Your choice between COB and COF depends on application requirements for rigidity, thermal management, and space constraints.

Material Differences: Substrates and Adhesives

Chip on Board (COB) uses rigid or flexible substrates, often made of glass epoxy or ceramic, providing durability and high thermal conductivity. Chip on Flex (COF) employs flexible polyimide substrates that offer superior bendability and lightweight properties ideal for compact electronic devices. Your choice of substrate and adhesive impacts device flexibility, heat dissipation, and reliability in assembly processes.

Manufacturing Processes: COB vs. COF

Chip on Board (COB) manufacturing involves directly mounting and wire bonding semiconductor chips onto a printed circuit board (PCB) with an encapsulating epoxy, enhancing electrical performance and durability. Chip on Flex (COF) manufacturing attaches chips onto flexible substrates using anisotropic conductive film (ACF) bonding, allowing for compact, bendable electronic assemblies ideal for wearable and flexible devices. The COB process typically offers robust mechanical stability, while COF provides greater design flexibility and space efficiency in electronic device fabrication.

Performance and Electrical Considerations

Chip on Board (COB) offers superior electrical performance due to its minimal interconnect lengths, resulting in reduced parasitic inductance and resistance, which enhances signal integrity and reliability. Chip on Flex (COF) provides flexible substrate advantages but typically exhibits higher electrical impedance and susceptibility to signal loss because of the flexible material's inherent properties. For high-frequency and high-performance applications, COB's direct die attachment minimizes electrical parasitics, whereas COF prioritizes mechanical flexibility over optimal electrical performance.

Size, Weight, and Design Flexibility

Chip on Board (COB) technology offers compact size and reduced weight by directly mounting bare semiconductor chips onto a substrate, enhancing electrical performance and heat dissipation. Chip on Flex (COF) integrates chips onto flexible circuits, providing superior design flexibility and enabling lightweight, bendable electronic assemblies ideal for wearable devices and compact gadgets. COF's adaptable form factor outperforms COB in applications requiring dynamic or irregular shapes without compromising miniaturization or weight constraints.

Reliability and Durability Comparison

Chip on Board (COB) technology offers excellent reliability due to its direct die attachment and protective resin coating, which enhances thermal management and mechanical stability. Chip on Flex (COF) provides superior flexibility for dynamic applications, but its durability may be compromised under continuous bending stresses compared to COB's rigid substrate. Your choice should consider the specific operational environment, where COB excels in static, high-reliability scenarios and COF suits flexible, lightweight designs.

Cost Implications and Scalability

Chip on Board (COB) offers lower initial material costs but can incur higher assembly expenses due to complex packaging, whereas Chip on Flex (COF) typically involves more costly flexible substrates but allows for streamlined integration and reduced labor costs in high-volume production. Scalability in COB is often limited by substrate rigidity and assembly complexity, while COF provides superior scalability through its flexible, thin-film interconnects that support miniaturization and mass production. Choosing between COB and COF heavily depends on budget constraints and volume requirements, as COF's upfront investment pays off in large-scale manufacturing efficiency.

Typical Applications for COB and COF

Typical applications for Chip on Board (COB) include LED lighting, power modules, and compact electronic devices where efficient heat dissipation and high wiring density are crucial. Chip on Flex (COF) is widely used in flexible displays, wearable electronics, and compact RFID tags, offering superior bendability and lightweight integration. Your choice depends on whether rigidity and thermal management (COB) or flexibility and space-saving design (COF) are priorities.

Future Trends in Electronic Packaging

Future trends in electronic packaging indicate a growing shift towards Chip on Flex (CoF) technology due to its superior flexibility, lightweight design, and enhanced integration with flexible circuits, enabling more compact and versatile device configurations. Chip on Board (CoB) remains relevant for high-performance applications requiring robust thermal management and electrical reliability. Your choice between CoB and CoF will depend on evolving demands for miniaturization, durability, and flexible electronics in emerging wearable, medical, and IoT devices.

Chip on Board vs Chip on Flex Infographic

libmatt.com

libmatt.com