Polyimide offers excellent thermal stability and chemical resistance, making it ideal for high-temperature applications, while benzocyclobutene (BCB) provides low dielectric constant and low moisture absorption, enhancing electrical performance in microelectronics. Choosing between polyimide and BCB depends on your specific needs for thermal endurance versus electrical insulation properties in device fabrication.

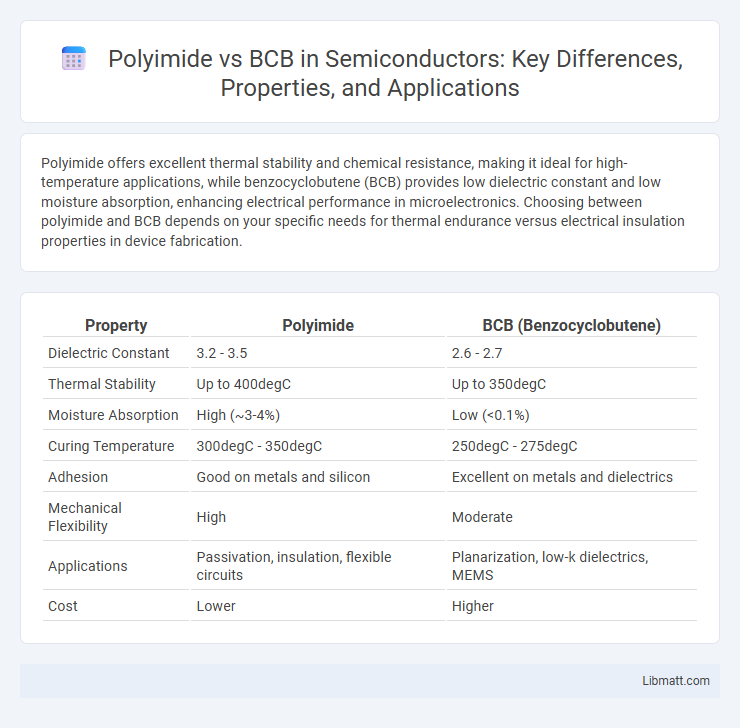

Table of Comparison

| Property | Polyimide | BCB (Benzocyclobutene) |

|---|---|---|

| Dielectric Constant | 3.2 - 3.5 | 2.6 - 2.7 |

| Thermal Stability | Up to 400degC | Up to 350degC |

| Moisture Absorption | High (~3-4%) | Low (<0.1%) |

| Curing Temperature | 300degC - 350degC | 250degC - 275degC |

| Adhesion | Good on metals and silicon | Excellent on metals and dielectrics |

| Mechanical Flexibility | High | Moderate |

| Applications | Passivation, insulation, flexible circuits | Planarization, low-k dielectrics, MEMS |

| Cost | Lower | Higher |

Introduction to Polyimide and BCB

Polyimide is a high-performance polymer known for its exceptional thermal stability, mechanical strength, and chemical resistance, making it widely used in microelectronics and aerospace applications. Benzocyclobutene (BCB) is a low-k dielectric material favored for its excellent electrical insulating properties, low moisture absorption, and ability to form smooth, planar surfaces in semiconductor manufacturing. Both materials serve critical roles in advanced packaging and interconnect technologies due to their unique thermal and electrical characteristics.

Chemical Structure and Composition

Polyimide consists of repeating imide groups characterized by aromatic or aliphatic backbones, providing exceptional thermal stability and mechanical strength due to its rigid molecular structure. Benzocyclobutene (BCB) features a cyclic benzene-fused four-membered ring that undergoes polymerization via ring-opening mechanisms, resulting in low dielectric constant and excellent adhesion properties. The distinct chemical compositions of polyimide and BCB directly influence their performance in high-temperature electronic and microelectronic applications.

Key Properties Comparison

Polyimide offers excellent thermal stability up to 400degC, superior mechanical strength, and outstanding chemical resistance, making it ideal for high-temperature and harsh environment applications. Benzocyclobutene (BCB) provides low dielectric constant (around 2.65) and minimal moisture absorption, optimizing performance in high-frequency electronic devices. When comparing adhesion properties, polyimide generally exhibits stronger substrate bonding, while BCB is favored for its planarization capabilities and low curing temperatures.

Thermal Stability and Performance

Polyimide offers exceptional thermal stability, maintaining structural integrity at temperatures up to 400degC, making it ideal for high-temperature applications. BCB (Benzocyclobutene) provides excellent thermal performance with a lower curing temperature around 250degC, which reduces thermal stress and improves integration with sensitive materials. Your choice between Polyimide and BCB should consider the maximum operating temperature and the thermal cycling conditions of your application for optimal performance.

Electrical Properties: Insulation and Dielectric Constants

Polyimide offers excellent insulation with a dielectric constant typically around 3.4 to 3.6, making it ideal for high-temperature electronic applications requiring stable electrical properties. Benzocyclobutene (BCB) features lower dielectric constants, approximately 2.6 to 2.7, providing superior electrical insulation and reduced signal loss in high-frequency circuits. Your choice between polyimide and BCB will depend on the specific insulation requirements and operating frequency of your electronic device.

Processability and Fabrication Techniques

Polyimide exhibits excellent processability with high thermal stability, making it suitable for spin coating, photolithography, and plasma etching in microfabrication. BCB (Benzocyclobutene) offers low dielectric constant and easy patterning through standard photolithographic processes, favored for semiconductor packaging and wafer bonding. While polyimide withstands harsh chemical environments and high temperatures, BCB enables low-temperature curing and compatibility with sensitive substrates, optimizing fabrication workflows in advanced electronics.

Applications in Microelectronics and Packaging

Polyimide and Benzocyclobutene (BCB) are widely utilized in microelectronics and packaging due to their excellent dielectric properties and thermal stability. Polyimide is favored for flexible circuit boards, insulating layers, and passivation due to its high thermal resistance and mechanical flexibility, while BCB is preferred for high-frequency interconnects and wafer-level packaging thanks to its low dielectric constant and superior planarization capabilities. Your choice between these materials depends on the specific demands of the application, such as thermal tolerance for polyimide or dielectric performance for BCB in advanced microelectronic devices.

Environmental and Mechanical Durability

Polyimide films exhibit outstanding environmental durability, resisting high temperatures up to 400degC and maintaining mechanical integrity under thermal cycling, making them ideal for harsh conditions. BCB (Benzocyclobutene) offers excellent mechanical flexibility and low moisture absorption, enhancing your device's resistance to environmental degradation without sacrificing performance. Choosing between Polyimide and BCB depends on your application's specific requirements for thermal endurance and mechanical resilience.

Cost and Availability Considerations

Polyimide offers greater cost efficiency and widespread availability due to its established production processes and numerous suppliers. BCB, or Benzocyclobutene, tends to be more expensive and less readily available, often requiring specialized manufacturing facilities. Your choice will depend on budget constraints and the accessibility of materials for your specific application.

Future Trends and Material Innovations

Polyimide and BCB (benzocyclobutene) are evolving with advanced formulations aimed at enhancing thermal stability, mechanical flexibility, and dielectric properties for next-generation electronics. Emerging trends highlight sustainable, low-temperature curing processes and novel copolymer blends to address miniaturization and high-frequency device demands. Your choice between polyimide and BCB will depend on the specific application requirements driven by future innovations in flexible displays, microelectronics, and photonics integration.

Polyimide vs BCB Infographic

libmatt.com

libmatt.com