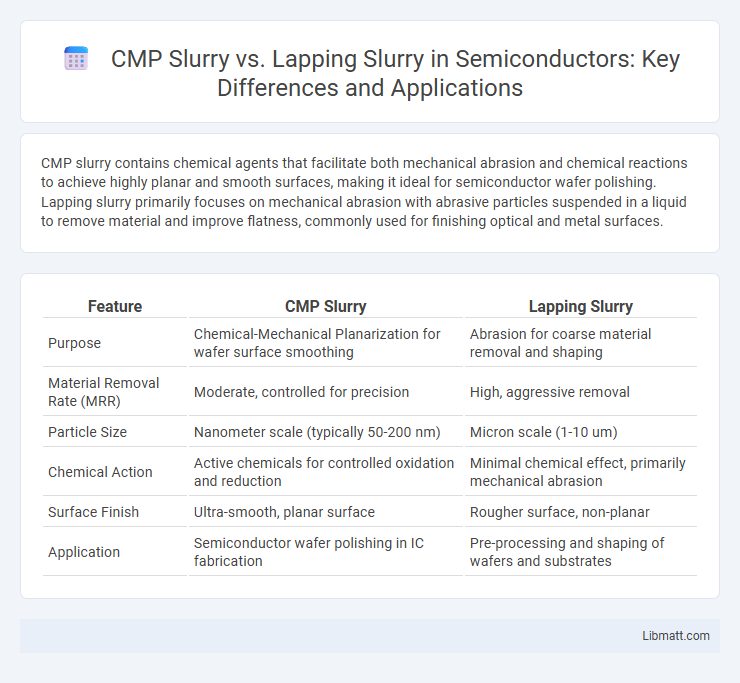

CMP slurry contains chemical agents that facilitate both mechanical abrasion and chemical reactions to achieve highly planar and smooth surfaces, making it ideal for semiconductor wafer polishing. Lapping slurry primarily focuses on mechanical abrasion with abrasive particles suspended in a liquid to remove material and improve flatness, commonly used for finishing optical and metal surfaces.

Table of Comparison

| Feature | CMP Slurry | Lapping Slurry |

|---|---|---|

| Purpose | Chemical-Mechanical Planarization for wafer surface smoothing | Abrasion for coarse material removal and shaping |

| Material Removal Rate (MRR) | Moderate, controlled for precision | High, aggressive removal |

| Particle Size | Nanometer scale (typically 50-200 nm) | Micron scale (1-10 um) |

| Chemical Action | Active chemicals for controlled oxidation and reduction | Minimal chemical effect, primarily mechanical abrasion |

| Surface Finish | Ultra-smooth, planar surface | Rougher surface, non-planar |

| Application | Semiconductor wafer polishing in IC fabrication | Pre-processing and shaping of wafers and substrates |

Introduction to CMP and Lapping Slurries

CMP slurry consists of chemically reactive and abrasive particles designed to polish semiconductor wafers with precise control, enhancing surface planarity and smoothness. Lapping slurry contains abrasive grains suspended in a liquid, primarily used for material removal and surface flattening in mechanical lapping processes. Understanding the differences between CMP slurry and lapping slurry helps your process achieve the desired surface quality and efficiency in semiconductor manufacturing or precision component finishing.

What is CMP Slurry?

CMP slurry is a specialized abrasive liquid used in chemical mechanical planarization to finely polish and planarize semiconductor wafers, ensuring smooth and defect-free surfaces. It contains a blend of chemical agents and abrasive particles that work synergistically to remove material selectively while minimizing surface damage. This slurry plays a critical role in achieving the precise surface uniformity required in integrated circuit fabrication.

What is Lapping Slurry?

Lapping slurry is a specialized abrasive fluid used in precision surface finishing processes to achieve ultra-flat and smooth surfaces on materials like metals, ceramics, and glass. Unlike CMP slurry, which combines chemical and mechanical actions for planarization, lapping slurry primarily relies on abrasive particles suspended in a liquid to mechanically wear down surface irregularities. Your selection between CMP slurry and lapping slurry depends on the level of surface flatness and finish quality required for your application.

Key Ingredients of CMP Slurry

CMP slurry primarily consists of abrasive particles such as silica or alumina suspended in a chemically reactive solution that targets specific materials during planarization. Key ingredients include oxidizers like hydrogen peroxide, pH adjusters to optimize the chemical activity, and corrosion inhibitors that protect the wafer surface from unwanted damage. This precise formulation enables efficient material removal and surface smoothness necessary for semiconductor manufacturing.

Key Ingredients of Lapping Slurry

Lapping slurry primarily consists of abrasive particles such as aluminum oxide, silicon carbide, and diamond powder suspended in a liquid medium, usually water or oil, to facilitate precise material removal and surface finishing. The particle size and concentration in the slurry are critical factors determining the efficiency and quality of the lapping process, with smaller particles providing finer finishes. Unlike CMP slurry, which includes chemical components for selective material removal, lapping slurry focuses on purely mechanical abrasion for uniform surface planarization.

Core Differences: CMP Slurry vs Lapping Slurry

CMP slurry contains engineered abrasive particles suspended in a chemically reactive solution designed for precise material removal and surface planarization in semiconductor fabrication, enabling controlled polishing with minimal damage. Lapping slurry consists of coarser, inert abrasives mixed with a lubricant, primarily used for general surface flattening and smoothing in mechanical applications without significant chemical interaction. The core difference lies in CMP slurry's chemical-mechanical action optimized for nanoscale uniformity, whereas lapping slurry relies on purely mechanical abrasion for macroscopic material removal.

Applications in Semiconductor Manufacturing

CMP slurry is primarily used in semiconductor manufacturing for chemical-mechanical planarization to achieve ultra-flat, defect-free surfaces on wafers, crucial for advanced integrated circuits. Lapping slurry finds applications in initial wafer thinning and surface smoothing processes, preparing substrates before fine planarization. Both slurries serve distinct roles in semiconductor fabrication, with CMP slurry enabling high-precision layer uniformity and lapping slurry providing preparatory surface conditioning.

Performance and Surface Finish Comparison

CMP slurry offers superior planarization performance by enabling precise material removal with minimal surface damage, resulting in ultra-smooth, defect-free finishes essential for semiconductor wafer fabrication. Lapping slurry, while effective for bulk material removal, often leaves microscale scratches and surface irregularities that require further polishing steps to achieve comparable smoothness. The optimized chemical-mechanical interaction in CMP slurries yields higher surface uniformity and enhanced control over removal rates compared to the abrasive-dominant action of lapping slurries.

Environmental and Safety Considerations

CMP slurry typically contains abrasive particles and chemical additives that can pose environmental hazards if not properly managed, requiring strict waste disposal protocols to prevent soil and water contamination. Lapping slurry often consists of finer abrasives suspended in water, generally presenting lower chemical risks but still necessitating proper handling to avoid inhalation or skin exposure. Both slurries demand appropriate personal protective equipment and adherence to regulatory standards to minimize health risks and environmental impact during use and disposal.

Choosing the Right Slurry for Precision Polishing

Selecting the appropriate slurry for precision polishing hinges on the key differences between CMP slurry and lapping slurry, where CMP slurry offers advanced chemical-mechanical properties ideal for achieving ultra-flat surfaces and nanoscale smoothness in semiconductor wafers. Lapping slurry, typically abrasive and used for coarse material removal, suits initial surface leveling but lacks the chemical components necessary for fine polishing. Proper selection depends on the material characteristics, desired surface finish, and polishing stage, with CMP slurry preferred for final polishing and lapping slurry for bulk material removal.

CMP Slurry vs Lapping Slurry Infographic

libmatt.com

libmatt.com