The Daisy Chain Test identifies breaks or faults in a series of connected wires by checking continuity throughout the entire chain, while the Kelvin Test measures low resistance in electrical connections using a four-wire method to ensure precise results. Your choice depends on whether you need to detect wiring faults rapidly or require highly accurate resistance measurements for quality assurance.

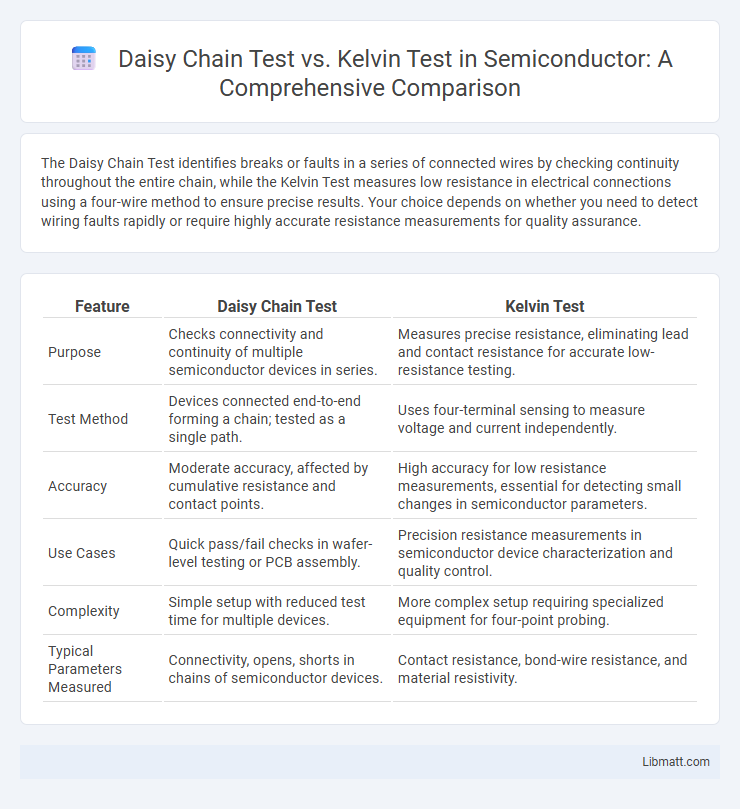

Table of Comparison

| Feature | Daisy Chain Test | Kelvin Test |

|---|---|---|

| Purpose | Checks connectivity and continuity of multiple semiconductor devices in series. | Measures precise resistance, eliminating lead and contact resistance for accurate low-resistance testing. |

| Test Method | Devices connected end-to-end forming a chain; tested as a single path. | Uses four-terminal sensing to measure voltage and current independently. |

| Accuracy | Moderate accuracy, affected by cumulative resistance and contact points. | High accuracy for low resistance measurements, essential for detecting small changes in semiconductor parameters. |

| Use Cases | Quick pass/fail checks in wafer-level testing or PCB assembly. | Precision resistance measurements in semiconductor device characterization and quality control. |

| Complexity | Simple setup with reduced test time for multiple devices. | More complex setup requiring specialized equipment for four-point probing. |

| Typical Parameters Measured | Connectivity, opens, shorts in chains of semiconductor devices. | Contact resistance, bond-wire resistance, and material resistivity. |

Introduction to Daisy Chain Test and Kelvin Test

The Daisy Chain Test measures the continuity of electrical connections in a series of components by linking them in a chain, often used to identify open circuits or connection faults. The Kelvin Test, also known as the four-wire measurement, accurately determines low resistance values by eliminating lead and contact resistance, commonly applied in precision electrical testing. Both methods are essential in quality control and troubleshooting of electronic assemblies but serve different purposes based on the level of resistance measurement and connection verification required.

Understanding the Basics of Daisy Chain Test

The Daisy Chain Test involves connecting multiple devices or components in series to verify continuity and identify open circuits, making it essential for troubleshooting PCB assemblies. This test method is efficient for detecting defects in interconnected paths but may not pinpoint precise resistance values or contact integrity. Compared to the Kelvin Test, which measures low-resistance contacts with high accuracy through a four-wire technique, the Daisy Chain Test primarily ensures circuit continuity without detailed resistance analysis.

Overview of the Kelvin Test Method

The Kelvin Test Method measures electrical resistance with four-wire sensing to eliminate the effect of lead and contact resistance, ensuring highly accurate and repeatable results. It is widely used for assessing low resistance connections in components such as printed circuit boards, cables, and connectors, particularly where precision is critical. By applying separate current and voltage leads, the Kelvin Test minimizes measurement errors, making it a preferred technique in quality control and failure analysis.

Key Differences Between Daisy Chain and Kelvin Test

The key differences between Daisy Chain and Kelvin Test lie in their measurement approaches and accuracy levels; Daisy Chain Test measures continuity across multiple components connected in series, making it ideal for quick fault detection but less precise. Kelvin Test, also known as four-wire measurement, uses separate pairs of current and voltage probes to eliminate lead resistance, providing highly accurate resistance readings critical for low-resistance measurements. Your choice depends on the required precision: Daisy Chain is suitable for general continuity checks, while Kelvin Test is essential for high-accuracy resistance testing in sensitive applications.

Applications of Daisy Chain Testing in Electronics

Daisy Chain Testing is commonly used in electronics manufacturing for testing the continuity and integrity of multiple interconnected components, such as printed circuit boards (PCBs), LED arrays, and wiring harnesses. This method efficiently detects short circuits and open circuits in series-connected devices, ensuring functional reliability before final assembly. Your production line benefits from faster fault localization and reduced testing time compared to traditional testing methods like the Kelvin Test.

Common Uses of Kelvin Testing in Industry

Kelvin testing is widely used in electronics manufacturing to measure low-resistance values accurately, ensuring the quality of electrical connections and detecting faults in circuits. Industries rely on Kelvin testing for applications such as validating PCB trace continuity, assessing battery contacts, and verifying wire bond integrity. Your product reliability improves significantly when employing Kelvin test methods to eliminate errors caused by lead and contact resistance.

Advantages and Limitations of Daisy Chain Test

The Daisy Chain Test offers advantages such as simplicity and rapid fault detection in series-connected components, making it effective for identifying open circuits and continuity issues in PCBs. However, it is limited by its inability to pinpoint specific fault locations within the chain and is less effective for detecting parallel faults or subtle resistance variations. Compared to the Kelvin Test, which provides precise low-resistance measurements and better fault localization, the Daisy Chain Test is less accurate but more cost-effective for quick diagnostics.

Benefits and Drawbacks of Kelvin Test

The Kelvin Test offers precise low-resistance measurements, minimizing contact resistance errors crucial for high-reliability electronic components. Its benefits include enhanced accuracy and repeatability, essential for quality control in manufacturing environments. However, the Kelvin Test can be more complex, requiring specialized equipment and careful probe placement, which may increase testing time and costs compared to simpler methods like the Daisy Chain Test.

Choosing Between Daisy Chain and Kelvin Test

Choosing between Daisy Chain and Kelvin Test depends on the precision required for your electrical measurements and the complexity of your circuit. Daisy Chain tests are ideal for quick continuity checks in simple, series-connected components, while Kelvin Tests provide highly accurate resistance measurements by eliminating lead and contact resistance, making them essential for low-resistance applications. Your choice should align with the need for speed versus measurement accuracy in your testing process.

Conclusion: Which Test Method is Best for Your Needs

Daisy Chain Test excels in quickly identifying open or short circuits across multiple components, making it ideal for basic continuity assessments and large-scale production environments. Kelvin Test offers superior accuracy in measuring low resistance values and detecting subtle contact resistance, thus suited for applications requiring precise electrical characterization. Your choice depends on whether speed or precision is the priority, with Daisy Chain Test better for efficiency and Kelvin Test optimal for detailed resistance analysis.

Daisy Chain Test vs Kelvin Test Infographic

libmatt.com

libmatt.com