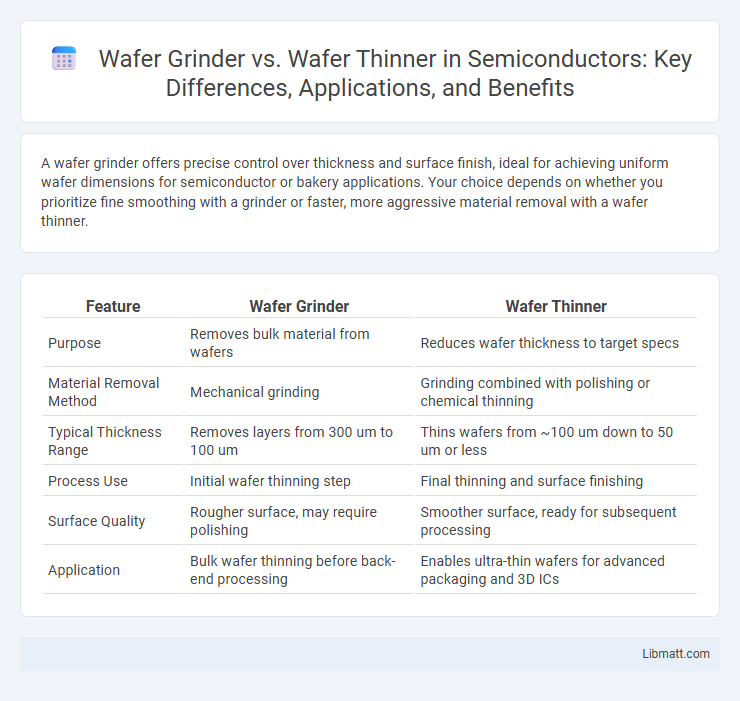

A wafer grinder offers precise control over thickness and surface finish, ideal for achieving uniform wafer dimensions for semiconductor or bakery applications. Your choice depends on whether you prioritize fine smoothing with a grinder or faster, more aggressive material removal with a wafer thinner.

Table of Comparison

| Feature | Wafer Grinder | Wafer Thinner |

|---|---|---|

| Purpose | Removes bulk material from wafers | Reduces wafer thickness to target specs |

| Material Removal Method | Mechanical grinding | Grinding combined with polishing or chemical thinning |

| Typical Thickness Range | Removes layers from 300 um to 100 um | Thins wafers from ~100 um down to 50 um or less |

| Process Use | Initial wafer thinning step | Final thinning and surface finishing |

| Surface Quality | Rougher surface, may require polishing | Smoother surface, ready for subsequent processing |

| Application | Bulk wafer thinning before back-end processing | Enables ultra-thin wafers for advanced packaging and 3D ICs |

Introduction to Wafer Processing Technologies

Wafer grinders and wafer thinners are essential wafer processing technologies used to reduce silicon wafer thickness for semiconductor manufacturing. Wafer grinders utilize mechanical grinding to achieve precise wafer thinning, enabling better device integration and thermal performance. Wafer thinners, often employing advanced mechanical and chemical techniques, provide uniform wafer thickness and improved surface quality critical for high-performance microelectronics.

What is a Wafer Grinder?

A Wafer Grinder is a precision machine used in semiconductor manufacturing to reduce the thickness of silicon wafers with high accuracy and uniformity. It employs abrasive wheels or belts to perform fine grinding, ensuring minimal surface damage and preparing wafers for subsequent processing steps. Wafer Grinders are essential for achieving the desired wafer thickness, flatness, and surface quality required in integrated circuit fabrication.

Understanding Wafer Thinners

Wafer thinners are specialized machines designed to reduce the thickness of semiconductor wafers uniformly, enhancing their electrical performance and packaging efficiency. Unlike wafer grinders that primarily remove bulk material, wafer thinners employ precise thinning techniques to achieve ultra-thin wafers without compromising structural integrity. Understanding wafer thinners is crucial for optimizing wafer handling and achieving higher yields in semiconductor manufacturing processes.

Key Differences Between Wafer Grinding and Thinning

Wafer grinding primarily reduces wafer thickness by removing material from the back side through abrasive processes, achieving high precision in thickness control and surface finish. Wafer thinning, on the other hand, involves both grinding and chemical-mechanical polishing (CMP) techniques to produce ultra-thin wafers with minimal damage, often essential for advanced semiconductor packaging. Key differences include the degree of thickness reduction achievable, process complexity, and the final wafer surface quality tailored to specific applications in microelectronics manufacturing.

Advantages of Wafer Grinding

Wafer grinding offers precise thickness control and uniform surface quality, ensuring optimal wafer flatness for advanced semiconductor fabrication. This method minimizes mechanical stress and reduces the risk of wafer breakage compared to traditional thinning techniques. Your wafer manufacturing process benefits from enhanced yield rates and improved device performance through wafer grinding.

Benefits of Wafer Thinning

Wafer thinning significantly improves semiconductor device performance by enhancing heat dissipation and enabling better electrical characteristics in microchips. This process reduces wafer thickness, allowing for more compact, flexible, and lightweight electronic components essential in modern technology. Your production efficiency and device reliability can greatly benefit from wafer thinning compared to traditional wafer grinding methods.

Applications in Semiconductor Manufacturing

Wafer grinders precisely reduce semiconductor wafer thickness for applications requiring enhanced electrical performance and device miniaturization, such as integrated circuit fabrication. Wafer thinners specialize in uniformly removing excess material to achieve targeted thickness profiles critical for advanced packaging and 3D stacking technologies. Both machines play vital roles in wafer preparation processes, optimizing yield and functionality in high-volume semiconductor manufacturing environments.

Equipment and Tools: Grinder vs Thinner

Wafer grinders utilize abrasive wheels or belts to precisely reduce wafer thickness by controlled material removal, ensuring uniformity and surface smoothness critical for semiconductor manufacturing. Wafer thinners, on the other hand, employ mechanical compression or polishing techniques to achieve wafer thinning, often focusing on finer adjustments and surface finishing. Both tools are essential in the wafer fabrication process, with grinders emphasizing coarse material removal and thinners optimizing final wafer dimensions and surface integrity.

Cost and Efficiency Comparison

Wafer grinders generally incur higher initial costs due to advanced technology and intricate mechanisms, but they offer superior efficiency and precision for large-scale semiconductor fabrication. Wafer thinners tend to be more cost-effective upfront but may require more frequent maintenance and produce lower throughput, impacting overall operational efficiency. Choosing between these tools depends on balancing budget constraints with desired output quality and processing speed in semiconductor manufacturing.

Choosing the Right Process for Your Wafer Fabrication

Selecting the appropriate process between wafer grinding and wafer thinning depends on the desired wafer thickness, surface quality, and overall fabrication requirements. Wafer grinding offers precise thickness control and flatness, ideal for initial wafer size reduction, while wafer thinning provides finer surface finish and reduced thickness for advanced packaging or 3D integration. Understanding the specific application needs ensures optimal performance, cost-effectiveness, and yield in semiconductor wafer fabrication.

Wafer Grinder vs Wafer Thinner Infographic

libmatt.com

libmatt.com