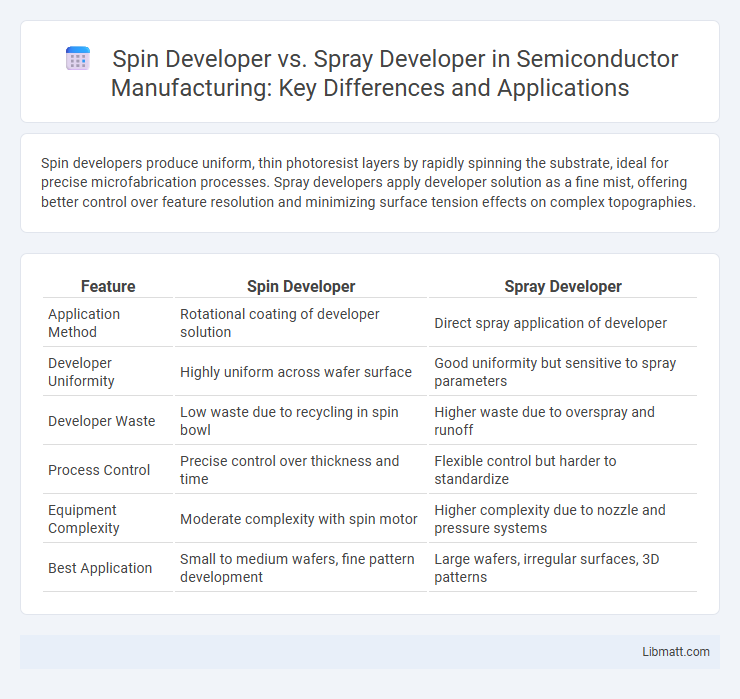

Spin developers produce uniform, thin photoresist layers by rapidly spinning the substrate, ideal for precise microfabrication processes. Spray developers apply developer solution as a fine mist, offering better control over feature resolution and minimizing surface tension effects on complex topographies.

Table of Comparison

| Feature | Spin Developer | Spray Developer |

|---|---|---|

| Application Method | Rotational coating of developer solution | Direct spray application of developer |

| Developer Uniformity | Highly uniform across wafer surface | Good uniformity but sensitive to spray parameters |

| Developer Waste | Low waste due to recycling in spin bowl | Higher waste due to overspray and runoff |

| Process Control | Precise control over thickness and time | Flexible control but harder to standardize |

| Equipment Complexity | Moderate complexity with spin motor | Higher complexity due to nozzle and pressure systems |

| Best Application | Small to medium wafers, fine pattern development | Large wafers, irregular surfaces, 3D patterns |

Introduction to Spin Developer and Spray Developer

Spin Developer and Spray Developer serve distinct roles in PCB manufacturing, with Spin Developer designed for precise, uniform application of photoresist using a spinning mechanism to ensure thin and consistent coatings. Spray Developer applies developer solution directly onto the board through controlled spray nozzles, allowing for efficient development of complex or uneven surfaces. Your choice between Spin Developer and Spray Developer depends on factors like substrate sensitivity, desired coating thickness, and production speed.

Core Principles of Spin and Spray Development

Spin developer employs spin coating to apply a uniform photoresist layer, leveraging centrifugal force and viscosity for precise film thickness control essential in semiconductor fabrication. Spray developer utilizes atomized droplets sprayed onto the wafer surface, promoting rapid, uniform development by enhancing developer diffusion and minimizing edge bead effects. Both methods optimize resist profile and resolution but differ in application technique and process parameters tailored to device requirements.

Equipment and Setup Differences

Spin developers require a spin coater to evenly distribute the developer solution over the substrate, ensuring uniform film development through centrifugal force. Spray developers utilize a spray system that atomizes the developer onto the surface, allowing precise control of development time and thickness, especially on non-flat or delicate substrates. Your choice between spin and spray developers depends on the specific equipment available and the desired uniformity or pattern complexity in the development process.

Process Workflow Comparison

Spin Developer offers a highly visual process workflow with drag-and-drop features that streamline application design and implementation, allowing rapid prototyping and iterative development tailored to your project needs. Spray Developer utilizes a code-centric workflow emphasizing modular, reusable components within a functional programming paradigm, enabling more granular control and scalability for complex systems. Understanding the distinct approaches in process workflow can help you choose Spin for faster, design-oriented development or Spray for detailed, code-driven architecture.

Substrate Compatibility and Handling

Spin developers are primarily compatible with flat, rigid substrates such as silicon wafers and glass slides, where uniform thin-film coating is essential. Spray developers excel in handling non-flat, large-area, or irregular substrates by delivering uniform coverage through atomized droplets, which prevents streaking and pooling. Both methods require careful parameter control, but spray development offers enhanced flexibility for complex geometries and non-planar surfaces compared to spin development.

Film Uniformity and Thickness Control

Spin developers excel in film uniformity due to their centrifugal force, which evenly spreads the developer solution across the wafer surface, resulting in consistent thickness control ideal for fine-feature semiconductor applications. Spray developers offer localized thickness adjustments by directing developer solution precisely onto targeted wafer areas, allowing you to optimize development in specific regions but sometimes at the expense of overall film uniformity. Spin development remains the preferred method when uniform film thickness and repeatable process control are critical for device performance.

Throughput and Scalability Considerations

Spin Developers offer higher throughput due to their efficient resource management, making them suitable for large-scale applications requiring rapid processing. Spray Developers excel in scalability by enabling distributed deployment across multiple nodes, which supports dynamic load balancing and fault tolerance. Your choice depends on whether your priority is maximizing throughput with optimized processing or achieving robust scalability for expanding workloads.

Cost Implications for Each Method

Spin Developer generally incurs higher initial equipment costs due to the need for sophisticated spin-coating machines, while spray development systems tend to be more cost-effective with simpler, less expensive apparatus. Operating expenses for Spin Developer include potential material waste and maintenance of precise spin conditions, whereas Spray Developer often features lower material consumption but may require frequent replacement of spray nozzles and cleaning systems. The choice between these methods depends on the budget constraints and production scale, with Spray Developer favored in cost-sensitive, small-batch processes and Spin Developer preferred for high-precision, large-volume fabrication despite higher upfront investment.

Ideal Applications for Spin vs Spray Developers

Spin developers are ideal for producing uniform thin photoresist layers on flat substrates, making them suitable for microelectronics and semiconductor wafer processing where precision and consistency are crucial. Spray developers excel in coating irregular, three-dimensional surfaces or large-area substrates, offering better coverage and control for applications like printed circuit boards and flexible electronics. Your choice depends on the substrate geometry and the desired thickness uniformity of the photoresist layer for optimal development results.

Choosing the Right Developer for Your Process

Selecting the right developer between Spin Developer and Spray Developer depends on your process requirements, such as uniformity and control. Spin Developers offer consistent coating thickness ideal for fine pattern resolution, while Spray Developers provide better coverage on complex topographies or uneven surfaces. Your choice influences development time, uniformity, and overall process efficiency, making it crucial to match the developer type to your specific application needs.

Spin Developer vs Spray Developer Infographic

libmatt.com

libmatt.com