A dry coat provides a matte, natural finish that repels dirt and moisture, enhancing your pet's overall cleanliness. Wet coat appears shiny and sleek but may attract more debris and require frequent grooming to maintain its luster.

Table of Comparison

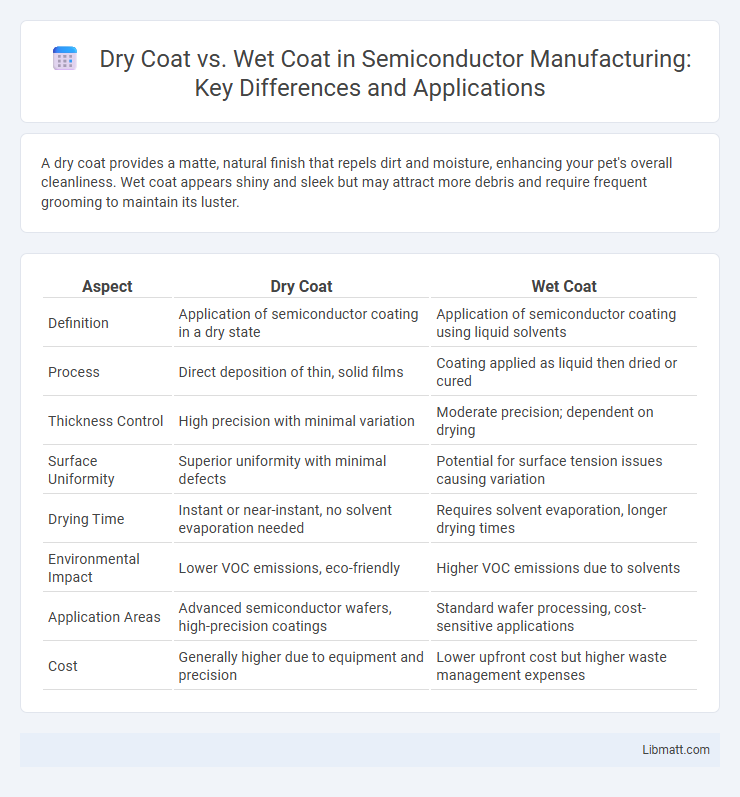

| Aspect | Dry Coat | Wet Coat |

|---|---|---|

| Definition | Application of semiconductor coating in a dry state | Application of semiconductor coating using liquid solvents |

| Process | Direct deposition of thin, solid films | Coating applied as liquid then dried or cured |

| Thickness Control | High precision with minimal variation | Moderate precision; dependent on drying |

| Surface Uniformity | Superior uniformity with minimal defects | Potential for surface tension issues causing variation |

| Drying Time | Instant or near-instant, no solvent evaporation needed | Requires solvent evaporation, longer drying times |

| Environmental Impact | Lower VOC emissions, eco-friendly | Higher VOC emissions due to solvents |

| Application Areas | Advanced semiconductor wafers, high-precision coatings | Standard wafer processing, cost-sensitive applications |

| Cost | Generally higher due to equipment and precision | Lower upfront cost but higher waste management expenses |

Introduction to Dry Coat vs Wet Coat

Dry coat refers to the fur or hair of animals when free from moisture, showcasing the true texture, thickness, and condition of the coat. Wet coat describes the same fur or hair soaked with water or other liquids, often appearing darker, slicker, and thinner due to moisture saturation. Understanding the difference between dry coat and wet coat is essential for proper grooming, health assessment, and maintenance of animals like dogs or horses.

Understanding Dry Coating: Definition and Uses

Dry coating refers to a process where a solid material is applied in a powder or granular form onto a substrate without the use of liquids, enhancing surface properties such as wear resistance, corrosion protection, or aesthetics. Common applications of dry coating include powder coating in automotive parts, industrial machinery, and household appliances, where it provides a durable, uniform finish that resists chipping and fading. This technique offers advantages like reduced volatile organic compounds (VOCs) emissions, faster curing times, and minimal environmental impact compared to traditional wet coatings.

What is Wet Coating? Key Features Explained

Wet coating refers to a process where a liquid layer is applied to a surface and allowed to dry, forming a protective or decorative film. Key features include its ability to create uniform coverage, enhance surface adhesion, and provide moisture resistance once cured. This method is commonly used in industries such as automotive painting, food packaging, and electronics for functional and aesthetic purposes.

Major Differences Between Dry Coat and Wet Coat

Dry coat refers to the outer layer of an animal's fur or feathers that lacks moisture, providing protection against environmental elements and aiding in insulation. Wet coat occurs when this outer layer becomes saturated with water, reducing its insulating properties and weight, which can affect the animal's mobility and temperature regulation. The major differences between dry coat and wet coat lie in their water content, thermal insulation effectiveness, and impact on the animal's comfort and protection from weather conditions.

Application Methods: Dry Coat vs Wet Coat

Dry coat application involves mixing cement with less water, resulting in a thicker, more workable consistency ideal for hand troweling and detailed finishing, enhancing surface durability and texture control. Wet coat application uses a higher water-cement ratio, enabling easier spread and leveling with tools like brushes or sprayers, suitable for larger surface areas requiring faster coverage. Your choice between dry coat and wet coat methods depends on the desired finish precision, surface size, and environmental conditions influencing drying times.

Performance and Durability Comparison

Dry coat materials typically offer superior durability due to their enhanced resistance to moisture, which prevents degradation and extends lifespan in harsh environments. Wet coat finishes provide better initial adhesion and coverage, improving overall performance in sealing surfaces but may require more maintenance over time. Choosing between dry coat and wet coat depends on the specific application's need for long-term resistance versus immediate protective qualities.

Industry-Specific Uses for Dry and Wet Coating

Dry coats are predominantly used in automotive and aerospace industries for corrosion resistance and surface protection, providing durability without the need for drying time. Wet coatings find applications in construction and furniture manufacturing, offering smooth finishes and enhanced adhesion on wood, metal, and concrete surfaces. Both coating types play critical roles in industrial processes where specific environmental conditions and performance requirements dictate the choice.

Environmental Impact: Which is More Sustainable?

Dry coat materials generally have a lower environmental impact due to reduced water usage and energy consumption during production compared to wet coat processes. Wet coat manufacturing often involves significant water waste and chemical runoff, leading to potential soil and water pollution. Sustainable alternatives prioritize dry coat techniques that minimize resource depletion and lower carbon emissions throughout the product lifecycle.

Cost Considerations: Dry Coat vs Wet Coat

Dry coat applications generally incur higher initial costs due to materials and labor intensity, but offer long-term durability that can reduce maintenance expenses. Wet coat treatments may have lower upfront prices, making them attractive for budget-conscious projects, yet they often require more frequent reapplications, increasing cumulative costs. You should weigh these cost factors against your project's timeline and expected lifespan to determine the most economical choice.

Choosing the Right Coating Method for Your Needs

Choosing between a dry coat and a wet coat depends on the specific application, environmental conditions, and desired durability. Dry coatings offer faster curing times and are ideal for low-humidity environments, while wet coats provide superior adhesion and protection against moisture, making them suitable for outdoor or high-humidity areas. Evaluating factors like substrate type, exposure conditions, and performance requirements ensures selecting the right coating method for optimal results and longevity.

Dry Coat vs Wet Coat Infographic

libmatt.com

libmatt.com