Sintering and reflow are two distinct processes used for joining materials in electronics manufacturing, where sintering fuses particles at high temperatures below melting points creating strong metallic bonds, while reflow involves melting solder paste to connect components on circuit boards. Your choice between sintering vs reflow depends on factors like conductivity requirements, thermal stability, and component sensitivity.

Table of Comparison

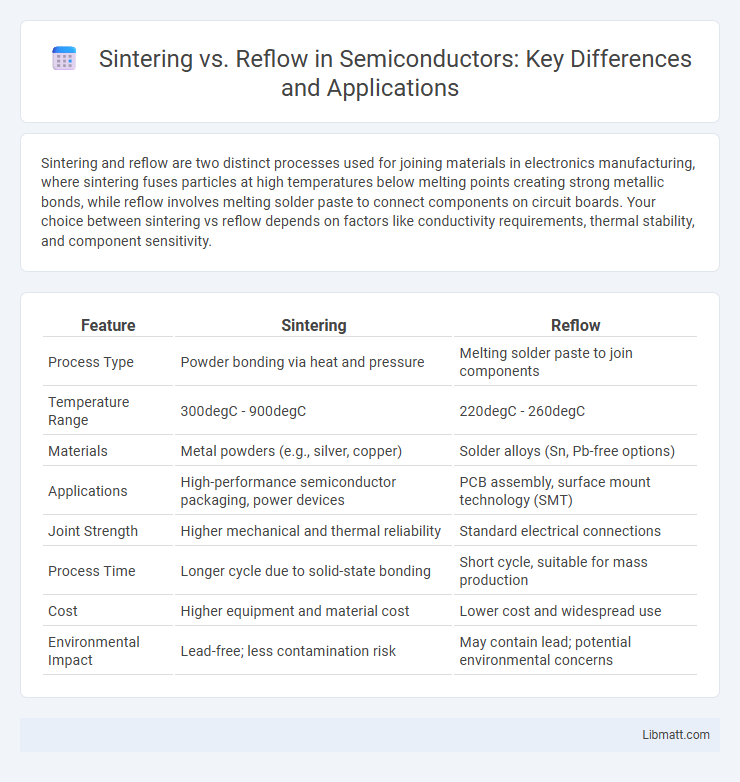

| Feature | Sintering | Reflow |

|---|---|---|

| Process Type | Powder bonding via heat and pressure | Melting solder paste to join components |

| Temperature Range | 300degC - 900degC | 220degC - 260degC |

| Materials | Metal powders (e.g., silver, copper) | Solder alloys (Sn, Pb-free options) |

| Applications | High-performance semiconductor packaging, power devices | PCB assembly, surface mount technology (SMT) |

| Joint Strength | Higher mechanical and thermal reliability | Standard electrical connections |

| Process Time | Longer cycle due to solid-state bonding | Short cycle, suitable for mass production |

| Cost | Higher equipment and material cost | Lower cost and widespread use |

| Environmental Impact | Lead-free; less contamination risk | May contain lead; potential environmental concerns |

Introduction to Sintering and Reflow

Sintering and reflow are key processes in electronics manufacturing used to join components and ensure reliable electrical connections. Sintering involves heating metal powders below their melting point to fuse particles together, creating strong, durable joints often used with silver-based pastes in power electronics. Reflow, on the other hand, melts solder paste to bond surface-mounted devices onto PCBs, enabling precise and efficient assembly in consumer electronics production.

Defining the Sintering Process

Sintering is a thermal process that fuses powdered materials into a solid mass by heating them below their melting point, enabling strong mechanical bonds and improved electrical conductivity. Unlike reflow soldering, which melts solder paste to join components, sintering is commonly used for advanced materials like silver nanoparticle inks in electronics manufacturing. This process enhances joint reliability and thermal stability, making it essential for high-performance semiconductor packaging and power electronics.

Understanding Reflow Soldering

Reflow soldering is a precise thermal process commonly used in surface-mount technology to attach electronic components to printed circuit boards (PCBs) by melting solder paste and forming strong electrical and mechanical connections. The controlled temperature profile during reflow soldering ensures optimal solder joint quality and prevents damage to sensitive components. Unlike sintering, which relies on pressure and heat to bond materials, reflow soldering primarily depends on the melting and solidification of solder to create reliable joints in electronic assembly.

Key Differences Between Sintering and Reflow

Sintering involves fusing particles together at temperatures below their melting points, primarily used for metals and ceramics, resulting in strong joints with enhanced electrical and thermal conductivity. Reflow focuses on melting solder paste to attach electronic components onto PCBs, using precise temperature profiles to ensure reliable solder joints without damaging components. Key differences lie in their temperature ranges, materials processed, and applications--sintering handles powders for structural integrity, while reflow targets solder connectivity in electronics assembly.

Material Compatibility: Sintering vs Reflow

Sintering enables strong bonding with materials such as silver, copper, and certain ceramics, offering superior thermal and electrical conductivity compared to reflow soldering, which primarily suits traditional solder alloys like tin-lead or lead-free compositions on common PCB substrates. Reflow processes accommodate a wider variety of PCB materials, including FR4 and high-temperature laminates, but may struggle with advanced materials requiring higher temperature tolerances or specialized metallization. Material compatibility in sintering supports high-performance applications in power electronics, while reflow remains versatile for conventional electronics assembly.

Temperature Profiles and Process Conditions

Sintering and reflow differ significantly in their temperature profiles and process conditions. Sintering typically involves sustained high temperatures, often above 200degC, maintained for extended periods to fuse particles or materials, ideal for metal joint formation. Reflow uses rapid heating to peak temperatures around 230-250degC, followed by controlled cooling, optimized specifically for solder paste melting in electronic assembly.

Equipment and Technology Requirements

Sintering requires specialized equipment with precise temperature control and often uses infrared or laser systems to achieve uniform heating and particle bonding. Reflow technology relies on convection or vapor phase ovens designed for rapid and controlled heating cycles to melt solder paste and form reliable joints. Both processes demand advanced control systems to monitor temperature profiles, ensuring consistent quality in electronic manufacturing.

Applications in Electronics Manufacturing

Sintering is primarily used in electronics manufacturing for advanced packaging and power devices, offering strong mechanical and electrical connections in high-temperature environments. Reflow soldering is widely applied in surface-mount technology (SMT) for attaching components to printed circuit boards (PCBs) with precise temperature profiles ensuring optimum solder joint quality. While sintering excels in high-reliability applications such as automotive and aerospace electronics, reflow remains the standard for mass production of consumer electronics due to its efficiency and compatibility with a wide range of solder pastes.

Advantages and Limitations of Each Technique

Sintering offers superior thermal and electrical conductivity along with enhanced mechanical strength, making it ideal for high-performance electronics, but it requires precise temperature control and can be costlier due to specialized equipment. Reflow is widely used for its compatibility with various solder types and efficient mass production in surface mount technology, though it may result in weaker joints and is less effective for high-power applications. Your choice between sintering and reflow should consider the specific performance requirements and production scale of your electronic assembly.

Choosing Between Sintering and Reflow

Choosing between sintering and reflow depends on the specific application requirements, such as the type of materials, temperature constraints, and desired electrical conductivity. Sintering is preferred for bonding metal nanoparticles, offering superior mechanical strength and thermal stability, while reflow is more suited for soldering standard electronic components with lead-free or traditional solder alloys. Evaluating factors like process temperature, joint reliability, and production speed helps determine the optimal method for assembly in advanced electronics manufacturing.

Sintering vs Reflow Infographic

libmatt.com

libmatt.com