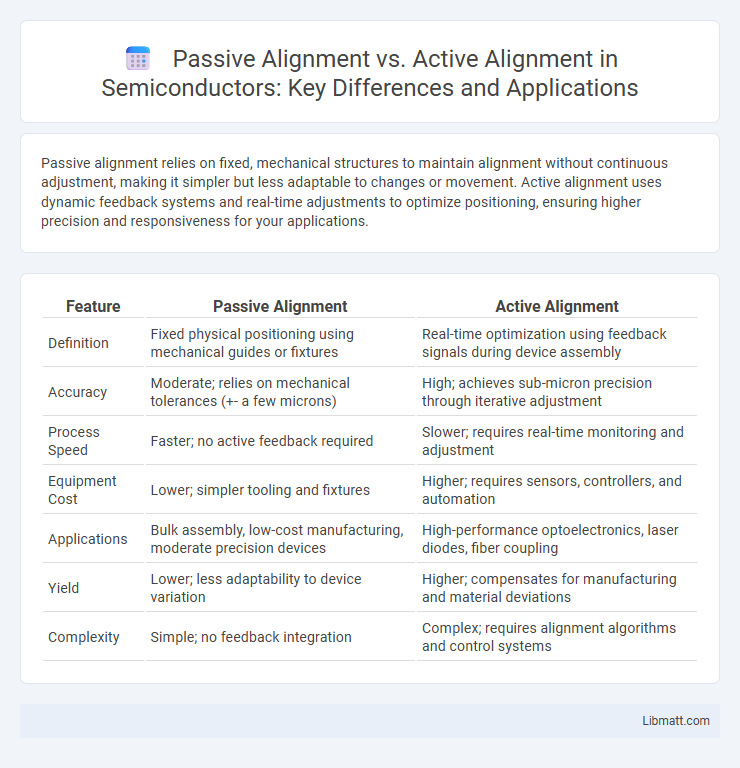

Passive alignment relies on fixed, mechanical structures to maintain alignment without continuous adjustment, making it simpler but less adaptable to changes or movement. Active alignment uses dynamic feedback systems and real-time adjustments to optimize positioning, ensuring higher precision and responsiveness for your applications.

Table of Comparison

| Feature | Passive Alignment | Active Alignment |

|---|---|---|

| Definition | Fixed physical positioning using mechanical guides or fixtures | Real-time optimization using feedback signals during device assembly |

| Accuracy | Moderate; relies on mechanical tolerances (+- a few microns) | High; achieves sub-micron precision through iterative adjustment |

| Process Speed | Faster; no active feedback required | Slower; requires real-time monitoring and adjustment |

| Equipment Cost | Lower; simpler tooling and fixtures | Higher; requires sensors, controllers, and automation |

| Applications | Bulk assembly, low-cost manufacturing, moderate precision devices | High-performance optoelectronics, laser diodes, fiber coupling |

| Yield | Lower; less adaptability to device variation | Higher; compensates for manufacturing and material deviations |

| Complexity | Simple; no feedback integration | Complex; requires alignment algorithms and control systems |

Introduction to Optical Alignment Methods

Passive alignment uses physical fixtures or mechanical guides for precise placement of optical components, offering cost-effectiveness and simplicity but lower precision. Active alignment involves real-time feedback with sensors and actuators to optimize the optical signal, providing superior accuracy essential for high-performance photonic devices. Your choice depends on the balance between alignment precision and production efficiency required for your optical system.

Defining Passive Alignment

Passive alignment refers to the precise positioning of optical components using pre-fabricated, fixed features such as mechanical stops or etched guides, eliminating the need for real-time adjustments during assembly. This technique leverages high-accuracy manufacturing processes to ensure components are aligned by design, resulting in faster production cycles and reduced dependency on specialized alignment equipment. Passive alignment is commonly employed in photonics packaging, where maintaining sub-micron tolerances between fibers and laser diodes enhances device performance and cost-effectiveness.

Defining Active Alignment

Active alignment is a precise semiconductor assembly process where the position of optical components is dynamically adjusted and monitored in real-time to maximize performance metrics like signal strength. This method involves using feedback systems and automated controls to fine-tune alignment during bonding, ensuring optimal device functionality. Your products benefit from enhanced accuracy and reduced signal loss through active alignment compared to passive alignment, which relies on fixed fixtures and lacks real-time adjustments.

Key Differences Between Passive and Active Alignment

Passive alignment relies on fixed mechanical fixtures to position components, ensuring consistent placement without real-time adjustment, making it cost-effective but less precise. Active alignment uses feedback systems and real-time monitoring, such as cameras or sensors, to dynamically adjust positions for higher accuracy and optimal performance, often employed in complex optical or electronic assemblies. Your choice depends on the required precision and budget, where passive suits mass production and active fits applications demanding tight tolerances.

Performance Comparison: Precision and Accuracy

Active alignment offers superior precision and accuracy compared to passive alignment by continuously adjusting component positions during the process, resulting in tighter tolerances. Passive alignment relies on fixed fixtures and mechanical stops, which can lead to lower alignment accuracy and greater variability between units. When your application demands high-performance optical or electronic assemblies, active alignment ensures optimal functionality through enhanced control and real-time feedback.

Cost Implications of Alignment Techniques

Passive alignment involves fixed, mechanical positioning of components, resulting in lower initial costs due to simpler equipment and processes but may lead to higher long-term expenses from reduced precision and potential performance issues. Active alignment uses real-time feedback and precision adjustments, increasing upfront costs with advanced machinery and longer setup times but offering improved accuracy, higher yield rates, and reduced operational costs over the product's lifecycle. Your decision should weigh immediate budget constraints against long-term value and product quality benefits associated with each alignment technique.

Speed and Scalability in Manufacturing

Passive alignment offers faster assembly times due to its reliance on predefined mechanical features, enabling high-throughput production with reduced cycle times. Active alignment requires precise real-time adjustments using feedback systems, which slows down the process but allows for higher accuracy in complex assemblies. In terms of scalability, passive alignment supports mass manufacturing with consistent speed, while active alignment is better suited for smaller volumes where precision outweighs throughput.

Typical Applications for Each Approach

Passive alignment is typically used in applications where cost-efficiency and scalability are critical, such as in high-volume optical transceiver manufacturing and consumer electronics. Active alignment finds its primary application in precision-demanding fields like fiber optic connectors, laser diode assembly, and medical devices, where optimal signal performance is essential. Both methods address the specific alignment accuracy needs dictated by the complexity and performance requirements of the end product.

Choosing the Right Alignment Method

Choosing the right alignment method depends on the balance between cost, precision, and production volume. Passive alignment offers a cost-effective solution with adequate accuracy for moderate tolerances by using mechanical fixtures to position components. Active alignment provides superior precision through real-time feedback and adjustment, making it ideal for high-performance optical systems where alignment accuracy directly impacts product quality.

Future Trends in Optical Alignment Technologies

Future trends in optical alignment technologies emphasize increased automation and the integration of AI-driven systems to enhance precision and reduce production time. Active alignment is expected to evolve with real-time feedback mechanisms using machine learning algorithms, improving adaptation to varying manufacturing conditions. You can anticipate significant advancements in passive alignment materials and microfabrication techniques that will complement active systems for more efficient and cost-effective optical device assembly.

Passive Alignment vs Active Alignment Infographic

libmatt.com

libmatt.com