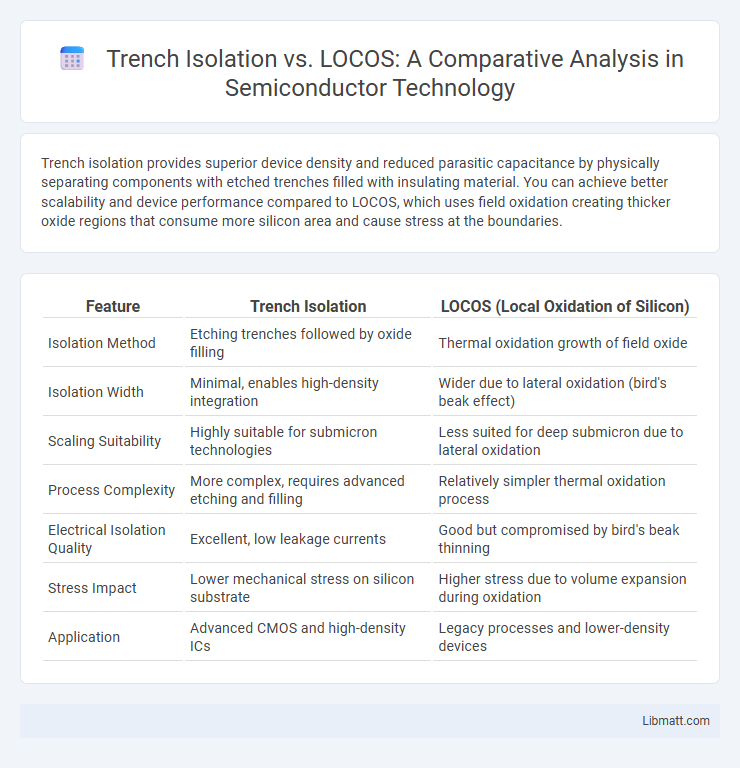

Trench isolation provides superior device density and reduced parasitic capacitance by physically separating components with etched trenches filled with insulating material. You can achieve better scalability and device performance compared to LOCOS, which uses field oxidation creating thicker oxide regions that consume more silicon area and cause stress at the boundaries.

Table of Comparison

| Feature | Trench Isolation | LOCOS (Local Oxidation of Silicon) |

|---|---|---|

| Isolation Method | Etching trenches followed by oxide filling | Thermal oxidation growth of field oxide |

| Isolation Width | Minimal, enables high-density integration | Wider due to lateral oxidation (bird's beak effect) |

| Scaling Suitability | Highly suitable for submicron technologies | Less suited for deep submicron due to lateral oxidation |

| Process Complexity | More complex, requires advanced etching and filling | Relatively simpler thermal oxidation process |

| Electrical Isolation Quality | Excellent, low leakage currents | Good but compromised by bird's beak thinning |

| Stress Impact | Lower mechanical stress on silicon substrate | Higher stress due to volume expansion during oxidation |

| Application | Advanced CMOS and high-density ICs | Legacy processes and lower-density devices |

Introduction to Trench Isolation and LOCOS

Trench Isolation and LOCOS (Local Oxidation of Silicon) are key semiconductor fabrication techniques used to electrically isolate devices on a silicon wafer. Trench Isolation involves etching narrow trenches into the substrate and filling them with insulating material, offering superior scaling and reduced parasitic capacitance compared to LOCOS. LOCOS creates isolation by thermally growing a thick field oxide, but suffers from the "bird's beak" effect, limiting its effectiveness in advanced integrated circuit designs.

Historical Development of Isolation Technologies

Trench Isolation and Local Oxidation of Silicon (LOCOS) represent key milestones in the evolution of semiconductor isolation technologies, with LOCOS introduced in the 1960s as a pioneering technique for defining device boundaries. Trench Isolation emerged in the 1980s to address limitations of LOCOS, such as lateral oxidation and scaling challenges, by physically etching trenches filled with dielectric materials to achieve better device separation and reduced parasitic capacitance. The transition from LOCOS to Trench Isolation reflects advances in fabrication precision and device miniaturization within integrated circuit manufacturing.

Fundamental Principles: Trench Isolation

Trench Isolation relies on etching deep trenches into the silicon substrate and filling them with insulating materials, such as silicon dioxide, to electrically separate adjacent devices on a chip. This method minimizes lateral diffusion and reduces parasitic capacitance, enhancing device performance and scalability in advanced semiconductor processes. Unlike LOCOS, which uses oxide growth to create isolation regions, trench isolation offers superior planarization and allows for higher packing density in integrated circuits.

Fundamental Principles: LOCOS

LOCOS (Local Oxidation of Silicon) is a semiconductor isolation technique that relies on thermal oxidation to create an insulating silicon dioxide region, effectively separating active devices on a silicon wafer. The process involves selectively exposing silicon areas to oxygen at high temperatures, causing localized growth of a thick oxide layer that limits lateral device interaction. LOCOS offers good electrical isolation but faces challenges such as "bird's beak" encroachment, which reduces the active device area and impacts scaling.

Process Flow Comparison

Trench Isolation involves etching narrow trenches into the silicon substrate, followed by oxide deposition and planarization, creating sharp and well-defined isolation regions, whereas LOCOS (Local Oxidation of Silicon) relies on thermal oxidation with nitride masks to form thicker, bird's-beak-shaped oxide regions. The trench process enables higher packing density and reduced lateral encroachment compared to LOCOS, which suffers from the bird's-beak effect limiting device scaling. Trench Isolation's precise etching and filling steps offer improved electrical isolation and minimized parasitic capacitance, critical for advanced CMOS technology nodes.

Advantages of Trench Isolation

Trench isolation offers superior scalability and reduced device spacing compared to LOCOS, enabling higher density integrated circuits. It minimizes lateral encroachment and bird's beak formation, improving active area precision and device performance. Enhanced electrical isolation and compatibility with shallow trench structures make trench isolation ideal for advanced CMOS technologies.

Advantages of LOCOS

LOCOS (Local Oxidation of Silicon) offers advantages such as excellent isolation quality with minimal parasitic capacitance and proven reliability in semiconductor fabrication. It provides a self-aligned oxidation process that reduces device leakage and enhances transistor performance, especially in analog and medium-scale integration circuits. LOCOS also has a simpler manufacturing process and is cost-effective compared to trench isolation, making it suitable for certain CMOS technologies.

Limitations and Challenges

Trench Isolation faces challenges such as increased manufacturing complexity and potential stress-induced defects due to deep etching and filling processes. LOCOS suffers from the "bird's beak" effect, which limits scaling by encroaching on active areas and causing non-uniform isolation widths. Both techniques encounter difficulties in achieving ultra-shallow isolation for advanced technology nodes, impacting device density and performance.

Applications in Modern Semiconductor Devices

Trench Isolation is widely used in modern semiconductor devices due to its superior scalability and reduced device size, enabling higher integration density in advanced CMOS technologies. LOCOS (Local Oxidation of Silicon) remains relevant for specific analog and power devices where stress-induced defects are minimized, providing robust isolation with relatively simple fabrication processes. Current semiconductor manufacturing predominantly favors shallow trench isolation (STI) for high-performance logic circuits, while LOCOS finds niche applications in MEMS and high-voltage components.

Future Trends in Isolation Technologies

Trench isolation and LOCOS (Local Oxidation of Silicon) are foundational semiconductor isolation techniques, with trench isolation offering superior planar surfaces and scalability as device dimensions shrink below 20 nm. Future trends emphasize advanced trench isolation methods incorporating high-k dielectrics and shallow trench isolation (STI) to minimize parasitic capacitance and leakage currents in ultra-scaled transistors. Your choice of isolation technology will increasingly depend on compatibility with emerging 3D architectures and low-power device requirements to enhance overall chip performance and reliability.

Trench Isolation vs LOCOS Infographic

libmatt.com

libmatt.com