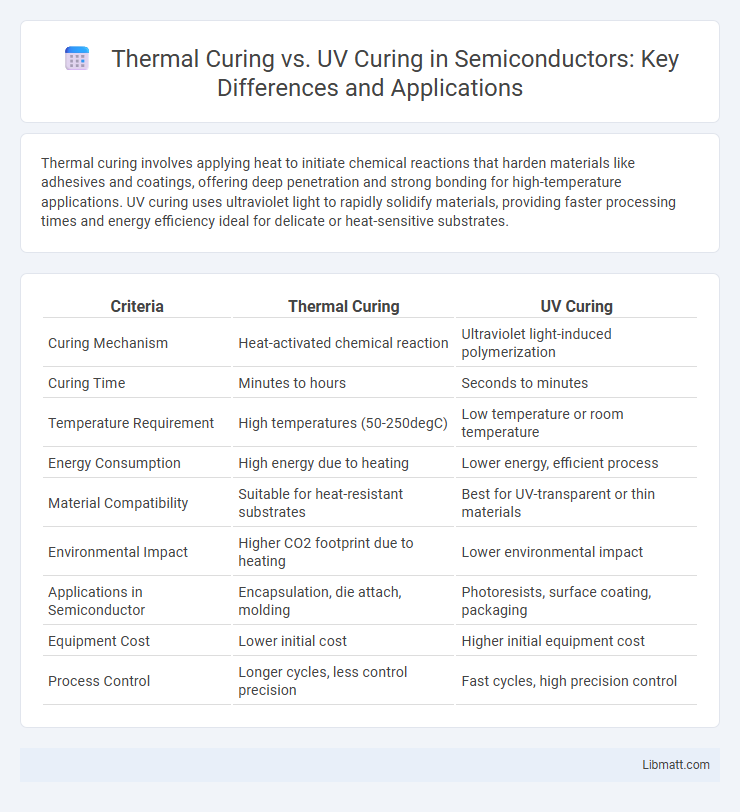

Thermal curing involves applying heat to initiate chemical reactions that harden materials like adhesives and coatings, offering deep penetration and strong bonding for high-temperature applications. UV curing uses ultraviolet light to rapidly solidify materials, providing faster processing times and energy efficiency ideal for delicate or heat-sensitive substrates.

Table of Comparison

| Criteria | Thermal Curing | UV Curing |

|---|---|---|

| Curing Mechanism | Heat-activated chemical reaction | Ultraviolet light-induced polymerization |

| Curing Time | Minutes to hours | Seconds to minutes |

| Temperature Requirement | High temperatures (50-250degC) | Low temperature or room temperature |

| Energy Consumption | High energy due to heating | Lower energy, efficient process |

| Material Compatibility | Suitable for heat-resistant substrates | Best for UV-transparent or thin materials |

| Environmental Impact | Higher CO2 footprint due to heating | Lower environmental impact |

| Applications in Semiconductor | Encapsulation, die attach, molding | Photoresists, surface coating, packaging |

| Equipment Cost | Lower initial cost | Higher initial equipment cost |

| Process Control | Longer cycles, less control precision | Fast cycles, high precision control |

Introduction to Curing Technologies

Thermal curing and UV curing are advanced techniques used to solidify coatings, adhesives, and inks by applying heat or ultraviolet light, respectively. Thermal curing relies on controlled heat to initiate chemical reactions that harden materials, making it ideal for heat-resistant substrates. UV curing offers rapid processing times with energy efficiency, suitable for applications requiring fast turnaround and environmental benefits, ensuring Your manufacturing process aligns with optimal productivity and sustainability.

Understanding Thermal Curing

Thermal curing involves the application of heat to initiate chemical reactions that harden or set materials such as adhesives, coatings, or composites. This process typically requires elevated temperatures ranging from 100degC to 250degC, depending on the substrate and curing agent, and can last from minutes to hours. Thermal curing provides robust mechanical strength and chemical resistance, making it ideal for applications requiring durable bond formation and stable material properties.

Exploring UV Curing

UV curing harnesses ultraviolet light to rapidly harden coatings, adhesives, and inks, offering significant time savings over traditional thermal curing methods. This process enables precise control of curing parameters, resulting in enhanced product durability and reduced energy consumption due to its low-temperature operation. Manufacturers benefit from UV curing's ability to deliver environmentally friendly and cost-effective solutions, particularly in industries like electronics, automotive, and printing.

Key Differences Between Thermal and UV Curing

Thermal curing uses heat to initiate a chemical reaction that solidifies materials, typically requiring extended curing times and higher energy consumption. UV curing involves exposure to ultraviolet light, triggering photopolymerization that results in rapid curing at lower temperatures and reduced energy use. The choice between thermal and UV curing depends on factors like substrate sensitivity, desired cure speed, and energy efficiency requirements.

Applications of Thermal Curing

Thermal curing is widely applied in industries requiring strong, durable bonds and heat-resistant coatings, such as aerospace, automotive, electronics, and composites manufacturing. It enhances material properties like mechanical strength and chemical resistance through controlled heat exposure. Typical products utilizing thermal curing include epoxy adhesives, powder coatings, and composite laminates, where extended heat cycles ensure optimal cross-linking and performance.

Applications of UV Curing

UV curing is extensively used in applications requiring rapid drying and high durability, such as in coatings for electronics, automotive parts, and medical devices. Its ability to cure inks, adhesives, and coatings almost instantly makes it ideal for high-speed manufacturing environments, enabling improved productivity and reduced energy consumption. You benefit from enhanced precision and environmental safety since UV curing emits minimal volatile organic compounds (VOCs) compared to thermal curing methods.

Advantages of Thermal Curing

Thermal curing offers superior adhesion and durability by allowing materials to fully polymerize through heat, resulting in stronger bonds and enhanced chemical resistance. It is compatible with a wide range of substrates and coatings, including those sensitive to UV light, making it ideal for thicker or pigmented materials. Your production process benefits from consistent curing depth and performance in applications where UV exposure may be insufficient or uneven.

Benefits of UV Curing

UV curing offers rapid processing times, significantly reducing production cycles compared to traditional thermal curing methods. This technology enhances material properties such as adhesion, hardness, and chemical resistance, providing superior durability for coatings and adhesives. You benefit from energy efficiency and lower emissions, making UV curing an environmentally friendly alternative in manufacturing industries.

Factors to Consider When Choosing a Curing Method

When choosing between thermal curing and UV curing, consider factors such as substrate compatibility, curing speed, and environmental conditions. Thermal curing requires higher temperatures and longer curing times, making it suitable for heat-resistant materials, while UV curing offers rapid processing and energy efficiency but depends on material transparency and exposure to UV light. Your selection should balance production speed, material properties, and energy consumption to optimize performance and cost-effectiveness.

Future Trends in Curing Technologies

Future trends in curing technologies emphasize faster processing times, enhanced energy efficiency, and reduced environmental impact through innovations like UV curing with advanced LED sources and hybrid curing systems combining thermal and UV methods. Research is increasingly directed toward developing sustainable curing materials and smart curing processes that improve product durability while minimizing volatile organic compound (VOC) emissions. Your manufacturing operations can benefit from adopting these cutting-edge technologies to stay competitive in industries demanding rapid, eco-friendly curing solutions.

Thermal Curing vs UV Curing Infographic

libmatt.com

libmatt.com