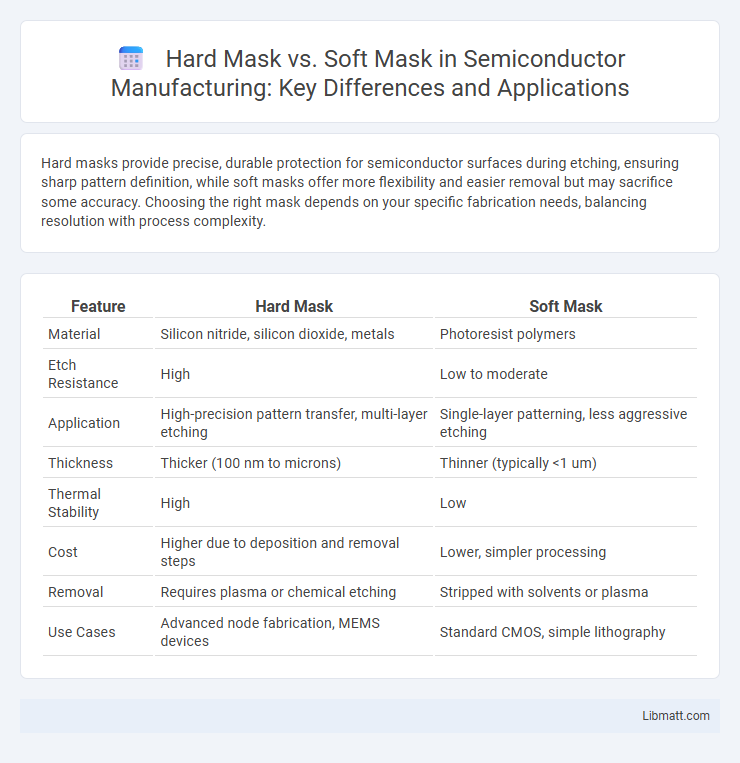

Hard masks provide precise, durable protection for semiconductor surfaces during etching, ensuring sharp pattern definition, while soft masks offer more flexibility and easier removal but may sacrifice some accuracy. Choosing the right mask depends on your specific fabrication needs, balancing resolution with process complexity.

Table of Comparison

| Feature | Hard Mask | Soft Mask |

|---|---|---|

| Material | Silicon nitride, silicon dioxide, metals | Photoresist polymers |

| Etch Resistance | High | Low to moderate |

| Application | High-precision pattern transfer, multi-layer etching | Single-layer patterning, less aggressive etching |

| Thickness | Thicker (100 nm to microns) | Thinner (typically <1 um) |

| Thermal Stability | High | Low |

| Cost | Higher due to deposition and removal steps | Lower, simpler processing |

| Removal | Requires plasma or chemical etching | Stripped with solvents or plasma |

| Use Cases | Advanced node fabrication, MEMS devices | Standard CMOS, simple lithography |

Introduction to Hard Masks and Soft Masks

Hard masks are robust, durable layers made from materials like silicon dioxide or silicon nitride, used primarily in semiconductor manufacturing to protect underlying substrates during etching processes. Soft masks, typically composed of photoresist materials, provide temporary protection and are easier to pattern but offer less resistance to harsh etching environments. Understanding the differences between hard masks and soft masks helps optimize your microfabrication process for precision and efficiency.

Key Differences Between Hard Masks and Soft Masks

Hard masks consist of materials like silicon dioxide or silicon nitride that provide superior etch resistance and dimensional stability during semiconductor fabrication compared to soft masks made from photoresist. Soft masks are typically organic polymers that are easier to pattern but offer lower durability and reduced resistance to plasma etching processes. The key differences lie in their material composition, etch resistance, and application suitability for high-precision etching versus flexible patterning needs.

Materials Used in Hard Masks vs Soft Masks

Hard masks typically use materials such as silicon dioxide (SiO2), silicon nitride (Si3N4), and metals like chromium, which offer excellent etch resistance and high thermal stability for precise pattern transfer in semiconductor fabrication. Soft masks use photoresist polymers or organic materials that are easier to apply and remove but provide lower durability and thinner film thickness, making them suitable for less aggressive etching processes. Your choice between hard and soft masks depends on the required etch selectivity, feature resolution, and process complexity in lithography applications.

Applications of Hard Masks in Industry

Hard masks are extensively used in semiconductor manufacturing for precise pattern transfer in photolithography, offering superior etch resistance compared to soft masks. These masks are essential in fabricating high-resolution microelectronics, MEMS devices, and advanced nanostructures where durability under aggressive plasma etching conditions is critical. Your choice of hard mask materials, such as silicon dioxide or silicon nitride, can significantly enhance device performance and yield in industrial applications.

Applications of Soft Masks in Industry

Soft masks are essential in semiconductor fabrication for pattern transfer processes, especially in photolithography and etching applications where flexibility and conformal coverage are crucial. Industries leverage soft masks to protect underlying materials during ion implantation and plasma etching, enabling precise control of micro- and nanoscale features. Your manufacturing processes benefit from soft masks' ability to accommodate non-planar surfaces and complex geometries, ensuring high-resolution patterning in advanced electronics and MEMS devices.

Advantages of Hard Masks Over Soft Masks

Hard masks offer superior etch resistance compared to soft masks, enabling more precise pattern transfer during semiconductor fabrication processes. They provide enhanced thermal stability, which is critical for high-temperature processing steps, reducing deformation and feature loss. Hard masks also improve selectivity and reduce contamination risks, leading to higher device performance and yield.

Limitations of Hard Masks vs Soft Masks

Hard masks offer superior etch resistance and dimensional control but are limited by their higher complexity, cost, and potential for substrate damage during removal. Soft masks provide easier processing and lower risk of damage, yet they suffer from reduced etch selectivity and lower durability under aggressive etching conditions. Your choice depends on balancing precision needs against process simplicity and material compatibility.

Cost Comparison: Hard Mask vs Soft Mask

Hard masks typically incur higher material and fabrication costs due to their use of durable materials like silicon nitride or metal films, which require more complex deposition and etching processes. Soft masks, made from photoresist or polymer materials, offer a cost-effective alternative with simpler application and removal steps, reducing overall process expenses. Choosing between hard and soft masks depends on balancing budget constraints with the precision and durability needs of the semiconductor or microfabrication process.

Selection Criteria: Choosing Between Hard and Soft Masks

Selection between hard and soft masks depends on the application's precision and material requirements. Hard masks offer superior etch resistance and dimensional accuracy, making them ideal for high-resolution semiconductor fabrication. Soft masks provide easier pattern transfer and flexibility but are less durable under aggressive etching conditions.

Future Trends in Masking Technologies

Future trends in masking technologies highlight the rise of hard masks due to their superior etch resistance and precision in semiconductor fabrication, especially as device nodes shrink below 5 nm. Soft masks continue to evolve with advanced polymers and photoresists offering improved resolution and process flexibility, catering to less stringent patterning needs. Your choice of masking technology will increasingly depend on balancing cost, precision, and scalability in next-generation integrated circuit manufacturing.

Hard Mask vs Soft Mask Infographic

libmatt.com

libmatt.com