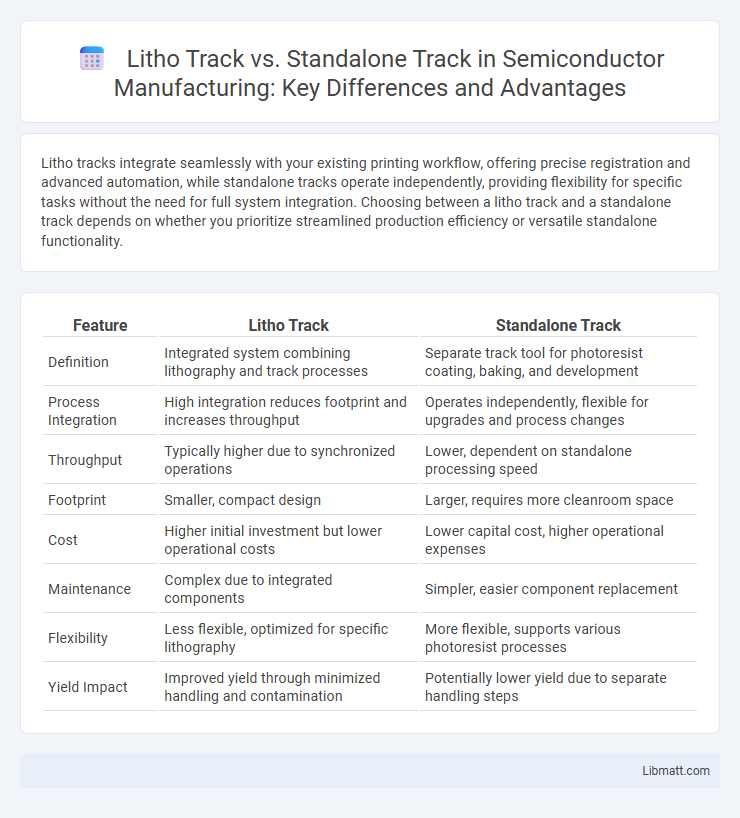

Litho tracks integrate seamlessly with your existing printing workflow, offering precise registration and advanced automation, while standalone tracks operate independently, providing flexibility for specific tasks without the need for full system integration. Choosing between a litho track and a standalone track depends on whether you prioritize streamlined production efficiency or versatile standalone functionality.

Table of Comparison

| Feature | Litho Track | Standalone Track |

|---|---|---|

| Definition | Integrated system combining lithography and track processes | Separate track tool for photoresist coating, baking, and development |

| Process Integration | High integration reduces footprint and increases throughput | Operates independently, flexible for upgrades and process changes |

| Throughput | Typically higher due to synchronized operations | Lower, dependent on standalone processing speed |

| Footprint | Smaller, compact design | Larger, requires more cleanroom space |

| Cost | Higher initial investment but lower operational costs | Lower capital cost, higher operational expenses |

| Maintenance | Complex due to integrated components | Simpler, easier component replacement |

| Flexibility | Less flexible, optimized for specific lithography | More flexible, supports various photoresist processes |

| Yield Impact | Improved yield through minimized handling and contamination | Potentially lower yield due to separate handling steps |

Introduction to Litho Track and Standalone Track

Litho Track is an integrated surface processing system designed for lithographic applications, offering precise control and compatibility with semiconductor manufacturing workflows. Standalone Track systems function independently to perform photolithography substrate coating, baking, and developing without requiring integration into a broader manufacturing line. Both systems optimize wafer fabrication but differ in their operational scope and integration capabilities within semiconductor production.

Key Differences Between Litho Track and Standalone Track

Litho Track integrates advanced lithography tools supported by real-time process monitoring and automated adjustments, enhancing precision and throughput in semiconductor manufacturing. Standalone Track operates independently without direct integration, often requiring manual interventions and separate process controls, leading to lower efficiency and increased error margins. Key differences include system integration level, process automation, and overall impact on yield optimization.

Benefits of Using Litho Track

Litho Track enhances film production efficiency by enabling precise, repeatable camera movements through integrated tracking systems, reducing setup time and operator error. Its advanced synchronization with Litho software allows for seamless post-production adjustments and consistent visual effects integration. Utilizing Litho Track boosts overall workflow accuracy and creative control compared to standalone track systems.

Advantages of Standalone Track Systems

Standalone Track Systems offer enhanced flexibility by allowing independent operation without the need for external control units, making installation simpler and more cost-effective. These systems provide improved scalability, enabling seamless integration with various machines or equipment without relying on a lithographic process. Their autonomous functionality reduces downtime and maintenance complexity, increasing overall operational efficiency in industrial applications.

Technology and Workflow Integration

Litho Track systems integrate advanced lithography with inline metrology and process control, enabling seamless workflow automation and real-time feedback for enhanced yield and precision. Standalone Track systems operate independently, offering flexibility but requiring manual data transfer and separate process steps, which may slow turnaround and increase variability. Integration in Litho Track reduces cycle time and improves alignment accuracy by synchronizing exposure, coating, and development phases within a unified platform.

Performance Comparison: Litho Track vs Standalone Track

Litho Track delivers superior performance by optimizing UI rendering through efficient reconciliation and background threading, resulting in smoother animations and faster load times compared to Standalone Track. Standalone Track often requires more manual intervention and can introduce latency due to less integrated state management and rendering optimizations. Your choice between Litho Track and Standalone Track will significantly impact the responsiveness and fluidity of your app's user interface.

Cost Considerations and ROI Analysis

Litho Track systems often require higher initial capital investment compared to Standalone Track setups due to integrated automation and advanced technology components. Your ROI analysis should factor in long-term savings from improved efficiency, reduced labor costs, and enhanced accuracy that Litho Track provides, offsetting the upfront expenditure over time. Standalone Track systems typically offer lower upfront costs but may result in higher operational expenses and slower returns, impacting overall profitability.

Industry Applications and Use Cases

Litho Track systems excel in semiconductor manufacturing, enabling precise wafer alignment and defect detection for integrated circuit production. Standalone Track solutions are versatile across pharmaceutical and biotechnology industries, optimizing automated substrate handling and chemical processing. Both systems enhance Your operational efficiency by catering to specific industry needs, ensuring high throughput and accuracy in specialized applications.

Challenges and Limitations of Each Approach

Litho Track systems often face challenges such as limited flexibility due to their integration with specific lithography equipment, leading to higher initial costs and complex maintenance requirements. Standalone Track solutions offer greater modularity and ease of customization but can suffer from lower throughput and potential alignment inconsistencies when integrated with other tools. Your choice between the two should weigh the trade-offs between integration efficiency and operational adaptability to optimize production outcomes.

Future Trends in Track System Development

Future trends in track system development emphasize integrating advanced materials and smart technologies to enhance durability and performance. Litho Track systems prioritize seamless scalability and modular design, enabling adaptive configurations for diverse industrial applications. Standalone Track solutions focus on cost-efficiency and simplified installation, catering to smaller-scale or niche market demands while gradually incorporating IoT connectivity for predictive maintenance.

Litho Track vs Standalone Track Infographic

libmatt.com

libmatt.com