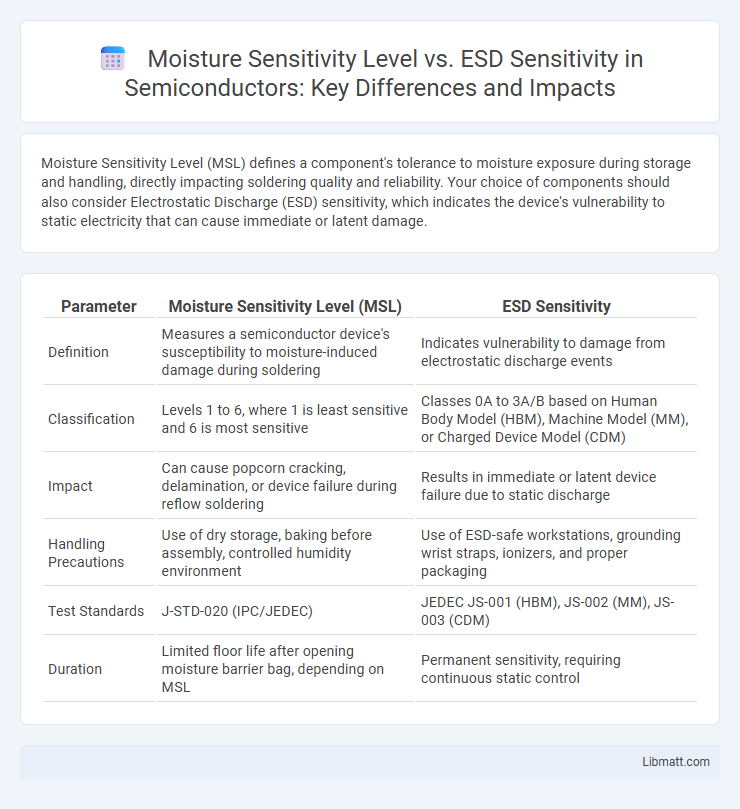

Moisture Sensitivity Level (MSL) defines a component's tolerance to moisture exposure during storage and handling, directly impacting soldering quality and reliability. Your choice of components should also consider Electrostatic Discharge (ESD) sensitivity, which indicates the device's vulnerability to static electricity that can cause immediate or latent damage.

Table of Comparison

| Parameter | Moisture Sensitivity Level (MSL) | ESD Sensitivity |

|---|---|---|

| Definition | Measures a semiconductor device's susceptibility to moisture-induced damage during soldering | Indicates vulnerability to damage from electrostatic discharge events |

| Classification | Levels 1 to 6, where 1 is least sensitive and 6 is most sensitive | Classes 0A to 3A/B based on Human Body Model (HBM), Machine Model (MM), or Charged Device Model (CDM) |

| Impact | Can cause popcorn cracking, delamination, or device failure during reflow soldering | Results in immediate or latent device failure due to static discharge |

| Handling Precautions | Use of dry storage, baking before assembly, controlled humidity environment | Use of ESD-safe workstations, grounding wrist straps, ionizers, and proper packaging |

| Test Standards | J-STD-020 (IPC/JEDEC) | JEDEC JS-001 (HBM), JS-002 (MM), JS-003 (CDM) |

| Duration | Limited floor life after opening moisture barrier bag, depending on MSL | Permanent sensitivity, requiring continuous static control |

Introduction to Moisture Sensitivity Level (MSL)

Moisture Sensitivity Level (MSL) defines the degree to which semiconductor devices are vulnerable to moisture-induced damage during soldering processes, with classifications ranging from MSL 1 (no sensitivity) to MSL 6 (extreme sensitivity). MSL ratings are critical for determining the floor life or the maximum time a component can be exposed to ambient conditions before re-baking is necessary, ensuring reliability during assembly. Understanding MSL is essential for preventing moisture-related failures such as popcorn cracking, which contrasts with Electrostatic Discharge (ESD) sensitivity that pertains to damage from electrostatic events.

Understanding ESD Sensitivity in Electronics

ESD sensitivity in electronics refers to the vulnerability of components to damage from electrostatic discharge events, which can cause immediate failure or latent defects. Understanding your device's ESD sensitivity is critical for implementing proper handling procedures, static control measures, and protective packaging to prevent costly malfunctions. Unlike moisture sensitivity level, which deals with damage from moisture exposure during soldering, ESD sensitivity focuses on protecting electronic parts from sudden electrical shocks.

Key Differences Between MSL and ESD Sensitivity

Moisture Sensitivity Level (MSL) measures a component's vulnerability to moisture-induced damage during soldering, while Electrostatic Discharge (ESD) Sensitivity assesses the risk of damage from static electricity events. MSL is primarily concerned with the absorption rate of moisture and the allowable floor life of the device before re-baking, whereas ESD sensitivity categorizes devices based on their susceptibility to voltage thresholds causing latent or immediate failure. Understanding these key differences helps you implement proper handling and storage protocols to protect sensitive electronic components effectively.

Impact of MSL on Component Handling and Storage

Moisture Sensitivity Level (MSL) significantly affects component handling and storage by dictating strict environmental controls to prevent moisture ingress that can cause device damage during soldering. Components with higher MSL ratings require specialized packaging, desiccants, and controlled humidity storage to maintain integrity and avoid failures like popcorning or delamination. Your adherence to MSL guidelines ensures reliable performance and prolongs the lifespan of sensitive electronic parts, contrasting with Electrostatic Discharge (ESD) sensitivity, which primarily demands static-free handling protocols.

ESD Sensitivity: Causes and Effects on Components

ESD sensitivity in electronic components arises from electrostatic discharge events that create sudden voltage spikes, potentially damaging internal circuitry. Common causes include human handling, improper grounding, and inadequate packaging during manufacturing and assembly processes. Effects of ESD damage range from immediate component failure to latent defects that reduce long-term reliability and performance of semiconductor devices.

Standard Classifications for MSL and ESD Sensitivity

Moisture Sensitivity Level (MSL) and Electrostatic Discharge (ESD) sensitivity are critical parameters in electronics manufacturing, each defined by standardized classifications to ensure component reliability. MSL is classified under IPC/JEDEC J-STD-020, ranging from Level 1 (no sensitivity) to Level 6 (highest sensitivity), indicating the floor life and handling precautions under specific humidity conditions. ESD sensitivity follows the JEDEC JESD22-A114 standard or the ESD Association's ESDA standards, categorizing devices from Class 0 (most sensitive) to Class 4 (least sensitive), which guides your static protection measures during assembly and handling.

Testing Methods for MSL and ESD Sensitivity

Testing methods for Moisture Sensitivity Level (MSL) primarily involve moisture desorption testing, including baking and controlled exposure to humidity, followed by standard reflow soldering to assess component degradation. Electrostatic Discharge (ESD) sensitivity testing utilizes models like Human Body Model (HBM), Machine Model (MM), and Charged Device Model (CDM), employing specialized equipment to simulate discharge events and measure component failure thresholds. Both testing processes ensure compliance with industry standards such as JEDEC for MSL and ANSI/ESDA/JEDEC protocols for ESD, ensuring component reliability in manufacturing environments.

Best Practices for Managing MSL and ESD in Manufacturing

Effective management of Moisture Sensitivity Level (MSL) and Electrostatic Discharge (ESD) sensitivity in manufacturing requires strict adherence to controlled storage environments and proper handling procedures. You should implement humidity-controlled packaging, bake-out processes for moisture-sensitive components, and use ESD-safe workstations equipped with grounding mats, wrist straps, and ionizers to prevent damage. Ensuring continuous training for personnel on MSL and ESD protocols significantly reduces component failures and enhances product reliability.

Common Failures Due to Improper MSL and ESD Control

Improper Moisture Sensitivity Level (MSL) handling can lead to device delamination, popcorn cracking, and solder joint failures during reflow soldering, severely impacting semiconductor reliability. Inadequate Electrostatic Discharge (ESD) control results in latent or catastrophic gate oxide damage, transistor threshold shifts, and increased leakage currents, compromising integrated circuit performance. Both MSL and ESD mishandling significantly increase failure rates in sensitive components such as advanced BGAs, QFNs, and CMOS devices.

Future Trends in MSL and ESD Protection Technologies

Emerging advancements in Moisture Sensitivity Level (MSL) testing utilize real-time humidity sensors and AI-driven predictive models to enhance the accuracy of moisture damage forecasting in semiconductor packaging. ESD protection technologies are evolving with the integration of novel materials like graphene and advanced circuit design techniques that offer superior electrostatic discharge resistance while minimizing device footprint. Future trends emphasize combining these innovations to develop comprehensive protective solutions that improve reliability and longevity in next-generation electronic components.

Moisture Sensitivity Level vs ESD Sensitivity Infographic

libmatt.com

libmatt.com