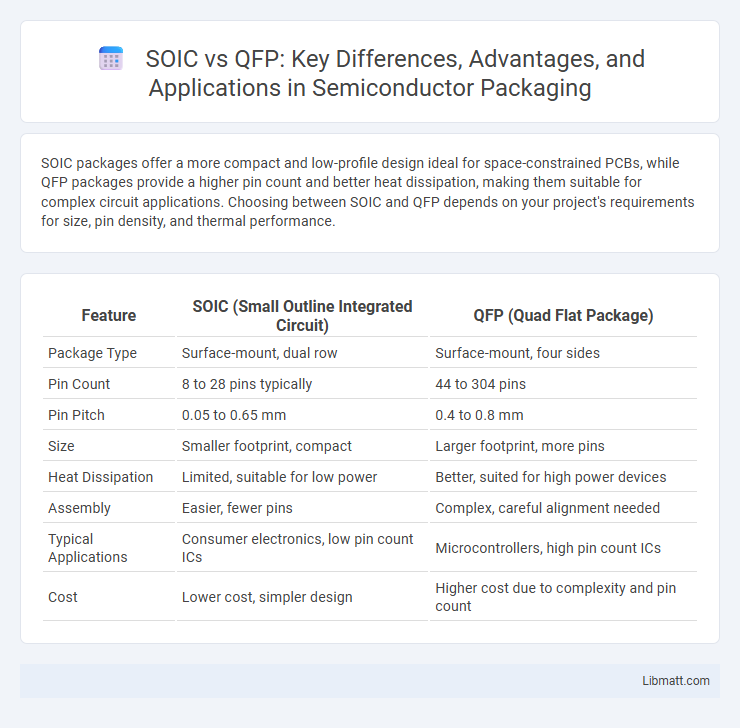

SOIC packages offer a more compact and low-profile design ideal for space-constrained PCBs, while QFP packages provide a higher pin count and better heat dissipation, making them suitable for complex circuit applications. Choosing between SOIC and QFP depends on your project's requirements for size, pin density, and thermal performance.

Table of Comparison

| Feature | SOIC (Small Outline Integrated Circuit) | QFP (Quad Flat Package) |

|---|---|---|

| Package Type | Surface-mount, dual row | Surface-mount, four sides |

| Pin Count | 8 to 28 pins typically | 44 to 304 pins |

| Pin Pitch | 0.05 to 0.65 mm | 0.4 to 0.8 mm |

| Size | Smaller footprint, compact | Larger footprint, more pins |

| Heat Dissipation | Limited, suitable for low power | Better, suited for high power devices |

| Assembly | Easier, fewer pins | Complex, careful alignment needed |

| Typical Applications | Consumer electronics, low pin count ICs | Microcontrollers, high pin count ICs |

| Cost | Lower cost, simpler design | Higher cost due to complexity and pin count |

Introduction to SOIC and QFP Packages

SOIC (Small Outline Integrated Circuit) packages feature a compact, rectangular shape with gull-wing leads extending from the shorter sides, making them ideal for space-constrained applications and easier soldering on printed circuit boards. QFP (Quad Flat Package) offers leads on all four sides, allowing for higher pin counts and better electrical performance in complex devices such as microcontrollers and processors. Understanding your design requirements helps determine whether the SOIC's simplicity or the QFP's extensive connectivity suits your project best.

Defining SOIC: Structure and Key Features

SOIC (Small Outline Integrated Circuit) is a surface-mount package characterized by its rectangular shape and gull-wing leads extending from both sides, designed for compact PCB layouts. Its structure typically features a plastic body with pins spaced at 1.27mm pitch, offering reliable electrical performance and ease of soldering. SOIC packages are favored in applications requiring moderate pin counts and enhanced thermal dissipation compared to traditional DIP packages.

Understanding QFP: Design and Specifications

QFP (Quad Flat Package) features a square or rectangular shape with leads extending from all four sides, enabling high pin counts and efficient PCB layout for complex ICs. Its design supports fine-pitch leads, typically ranging from 0.4mm to 1.0mm, allowing for compact and high-density circuit board integration. Specifications often highlight thermal performance, lead pitch, and package dimensions critical for surface-mount technology applications.

SOIC vs QFP: Dimensional Comparisons

SOIC (Small Outline Integrated Circuit) packages generally feature a more compact, rectangular form with a typical thickness of 1.75 mm and lead pitch ranging from 1.27 mm to 0.95 mm, making them suitable for limited board space. QFP (Quad Flat Package) dimensions are larger, with a square or rectangular shape, lead pitch commonly between 0.4 mm and 1.0 mm, and package thickness around 1.0 to 1.5 mm, offering a higher pin count in a broader footprint. The subtle differences in footprint area and lead pitch between SOIC and QFP influence their application in terms of PCB layout density and thermal management.

Pin Count and Pitch: SOIC vs QFP Differences

SOIC packages typically have pin counts ranging from 8 to 28 pins with a lead pitch of 1.27 mm, making them suitable for moderate-density applications. QFP packages offer much higher pin counts, often from 32 up to 256 pins, with finer pitches usually between 0.4 mm to 0.8 mm, enabling more complex circuitry and increased connection density. The larger pin count and smaller pitch of QFP make it ideal for high-performance microcontrollers and processors, whereas SOIC is preferred for simpler, lower-pin-count devices.

Assembly and Soldering Process Overview

SOIC packages feature gull-wing leads that simplify automated soldering and reduce the risk of bridging during assembly, making them ideal for surface-mount technology (SMT) processes. QFP packages, with their fine-pitch leads extending on all four sides, require precise alignment and solder paste application, often necessitating advanced inspection methods like X-ray to ensure proper solder joint formation. Both package types benefit from reflow soldering techniques, but QFP's lead density demands stricter thermal profiling and solder paste deposition control for reliable assembly.

Application Suitability: Choosing Between SOIC and QFP

SOIC (Small Outline Integrated Circuit) packages offer compact size and ease of soldering, making them ideal for moderate pin counts in consumer electronics and automotive applications. QFP (Quad Flat Package) provides higher pin density and better heat dissipation, suited for complex microcontrollers and processors in telecommunications and industrial systems. Selecting between SOIC and QFP depends on required pin count, board space constraints, thermal management, and manufacturing capabilities.

Thermal Performance and Reliability

SOIC packages typically offer better thermal performance due to their smaller size and shorter lead lengths, facilitating more efficient heat dissipation compared to QFPs. QFP packages, while larger and capable of handling higher pin counts, may experience increased thermal resistance and potential reliability issues under high power or thermal cycling conditions. Your choice between SOIC and QFP should consider the specific thermal management requirements and reliability expectations of your electronic design.

Cost Considerations in SOIC and QFP Selection

SOIC packages generally offer lower manufacturing and assembly costs due to their smaller footprint and simpler lead structure compared to QFP packages. QFPs tend to be more expensive because of their higher pin count and finer pitch, which require more precise manufacturing processes and advanced inspection techniques. When selecting between SOIC and QFP, your budget constraints and required pin density should guide the decision to optimize overall project costs.

Future Trends in IC Packaging: SOIC and QFP

Future trends in IC packaging highlight the evolution of SOIC (Small Outline Integrated Circuit) and QFP (Quad Flat Package) towards enhanced miniaturization and improved thermal management to meet the demands of high-performance electronics. SOIC continues to be favored for its compact, low-profile design suitable for automated assembly, while QFP evolves with finer lead pitches to accommodate increased pin counts and signal integrity in complex circuits. Advances in materials and die-attach technologies for both SOIC and QFP are driving greater reliability and integration in applications such as IoT devices, automotive electronics, and high-speed communication systems.

SOIC vs QFP Infographic

libmatt.com

libmatt.com