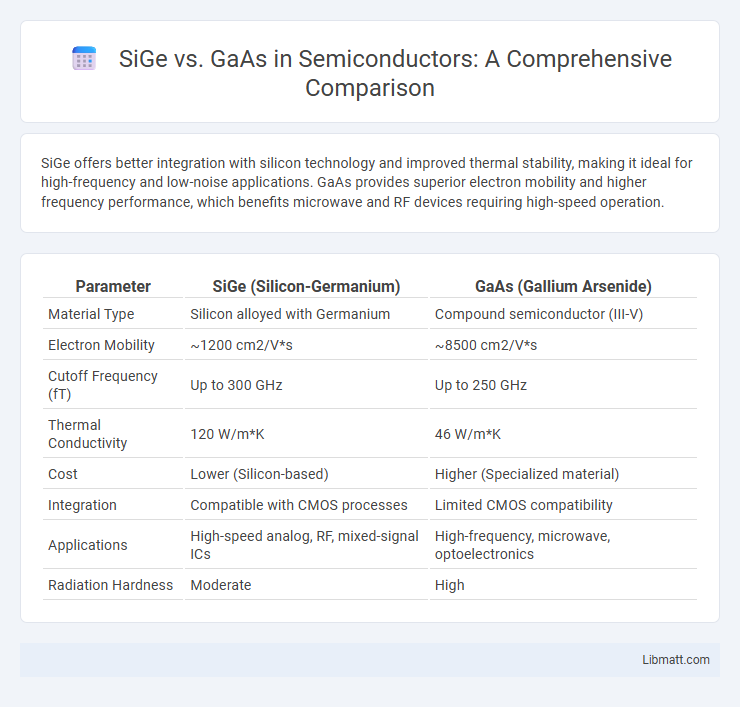

SiGe offers better integration with silicon technology and improved thermal stability, making it ideal for high-frequency and low-noise applications. GaAs provides superior electron mobility and higher frequency performance, which benefits microwave and RF devices requiring high-speed operation.

Table of Comparison

| Parameter | SiGe (Silicon-Germanium) | GaAs (Gallium Arsenide) |

|---|---|---|

| Material Type | Silicon alloyed with Germanium | Compound semiconductor (III-V) |

| Electron Mobility | ~1200 cm2/V*s | ~8500 cm2/V*s |

| Cutoff Frequency (fT) | Up to 300 GHz | Up to 250 GHz |

| Thermal Conductivity | 120 W/m*K | 46 W/m*K |

| Cost | Lower (Silicon-based) | Higher (Specialized material) |

| Integration | Compatible with CMOS processes | Limited CMOS compatibility |

| Applications | High-speed analog, RF, mixed-signal ICs | High-frequency, microwave, optoelectronics |

| Radiation Hardness | Moderate | High |

Introduction to SiGe and GaAs Technologies

SiGe (Silicon-Germanium) combines silicon's compatibility with CMOS processes and germanium's enhanced electron mobility, enabling high-speed and low-power semiconductor devices. GaAs (Gallium Arsenide) offers superior electron mobility and direct bandgap properties, making it ideal for high-frequency and optoelectronic applications. Your choice between SiGe and GaAs technologies depends on factors like cost, integration complexity, and performance requirements in RF and microwave systems.

Material Composition and Structure

SiGe (Silicon-Germanium) is a semiconductor alloy combining silicon and germanium atoms in a crystalline lattice, offering enhanced electron mobility compared to pure silicon. GaAs (Gallium Arsenide) features a compound semiconductor structure with gallium and arsenic atoms arranged in a zinc blende crystal lattice, providing superior high-frequency performance and electron velocity. Your choice between SiGe and GaAs depends on the need for integration with silicon technology versus high-speed and high-frequency applications.

Electronic Properties Comparison

SiGe (Silicon-Germanium) offers higher electron mobility than pure silicon, enhancing carrier speed and device switching performance, while GaAs (Gallium Arsenide) exhibits even greater electron mobility and direct bandgap properties, enabling superior high-frequency and optoelectronic applications. GaAs devices generally achieve higher electron velocity and lower noise figures, making them ideal for microwave and millimeter-wave communications. However, SiGe provides better integration with silicon-based CMOS technology, offering cost-effective solutions with competitive speed and power efficiency in mixed-signal and RF circuits.

Performance in High-Frequency Applications

SiGe technology offers superior noise performance and higher integration density compared to GaAs, making it ideal for high-frequency applications such as RF front-ends and millimeter-wave circuits. GaAs excels in electron mobility and saturation velocity, enabling higher power output and efficiency at microwave frequencies, which benefits radar and satellite communication systems. SiGe's compatibility with CMOS processes also allows cost-effective, large-scale production of mixed-signal and digital circuits for advanced 5G and IoT applications.

Thermal Management and Efficiency

SiGe (Silicon-Germanium) devices offer superior thermal conductivity compared to GaAs (Gallium Arsenide), enabling better heat dissipation and enhanced thermal management in high-power applications. GaAs devices typically exhibit higher electron mobility, which can translate to higher efficiency at high frequencies but suffer from greater thermal resistance, challenging cooling efforts. When selecting your semiconductor technology, prioritize SiGe for applications demanding efficient thermal handling and GaAs for scenarios where high-frequency efficiency outweighs thermal constraints.

Integration with CMOS Processes

SiGe offers superior integration with CMOS processes due to its compatibility with silicon substrates, enabling seamless monolithic integration of analog and digital circuits. GaAs, while providing higher electron mobility and superior high-frequency performance, poses challenges in integration with standard CMOS technology because of its distinct lattice structure and fabrication requirements. Consequently, SiGe is often preferred for applications requiring high integration density and cost-effective CMOS-compatible manufacturing.

Cost and Manufacturing Considerations

SiGe technology offers lower manufacturing costs due to compatibility with existing silicon fabrication infrastructure, enabling high-volume production and easier integration with CMOS processes. GaAs manufacturing involves more expensive substrates and complex fabrication steps, resulting in higher costs and lower wafer sizes. Cost-effective mass production favors SiGe for applications requiring integration and scalability, while GaAs remains preferred in high-frequency or high-power niche markets despite higher expenses.

Reliability and Longevity

SiGe (Silicon-Germanium) technology offers higher reliability and longer operational lifespan compared to GaAs (Gallium Arsenide) due to its superior thermal stability and resistance to mechanical stress. GaAs devices, while excellent for high-frequency performance, often face issues with lattice defects and oxidation that can reduce their durability over time. Your choice of SiGe ensures enhanced reliability in harsh environments and improved longevity for sustained performance in critical applications.

Key Applications and Use Cases

SiGe technology excels in high-frequency applications such as RF front-end modules for smartphones, automotive radar systems, and low-noise amplifiers due to its superior integration with silicon-based circuits and cost efficiency. GaAs is prominent in satellite communications, microwave frequency amplifiers, and high-power RF devices because of its high electron mobility and intrinsic material properties that support higher frequency performance and power output. Both materials serve crucial roles in wireless communication systems, with SiGe favored for cost-sensitive integrated solutions and GaAs chosen for high-performance, high-frequency applications.

Future Trends in SiGe and GaAs Development

Future trends in SiGe and GaAs development emphasize enhanced high-frequency performance and energy efficiency for 5G and beyond applications. SiGe technology continues advancing with innovative transistor scaling and improved integration, making it ideal for cost-effective, high-speed communication systems. Your choice between SiGe and GaAs will depend on balancing the need for low power consumption versus superior electron mobility and frequency capabilities.

SiGe vs GaAs Infographic

libmatt.com

libmatt.com