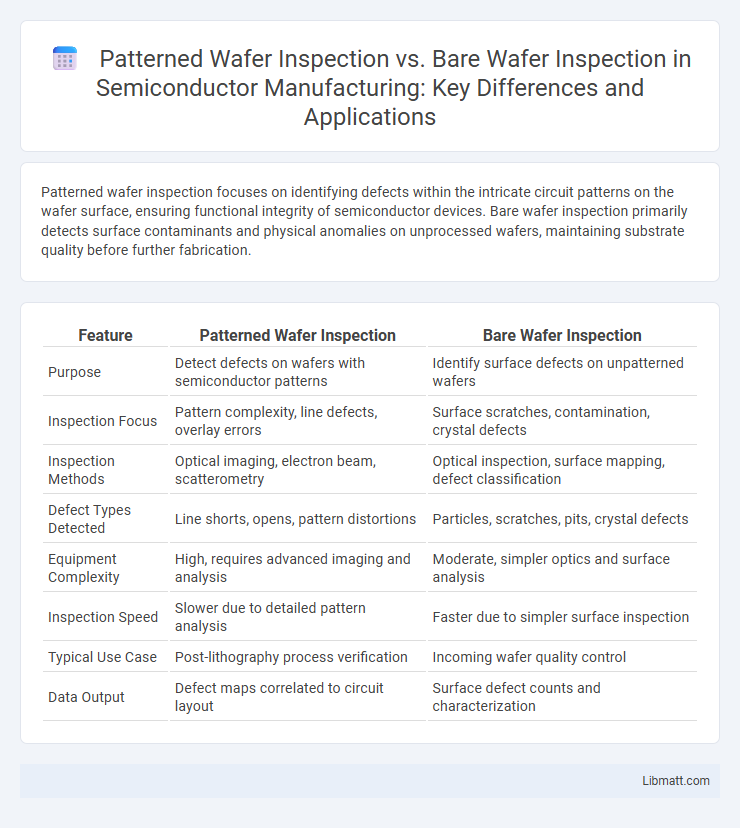

Patterned wafer inspection focuses on identifying defects within the intricate circuit patterns on the wafer surface, ensuring functional integrity of semiconductor devices. Bare wafer inspection primarily detects surface contaminants and physical anomalies on unprocessed wafers, maintaining substrate quality before further fabrication.

Table of Comparison

| Feature | Patterned Wafer Inspection | Bare Wafer Inspection |

|---|---|---|

| Purpose | Detect defects on wafers with semiconductor patterns | Identify surface defects on unpatterned wafers |

| Inspection Focus | Pattern complexity, line defects, overlay errors | Surface scratches, contamination, crystal defects |

| Inspection Methods | Optical imaging, electron beam, scatterometry | Optical inspection, surface mapping, defect classification |

| Defect Types Detected | Line shorts, opens, pattern distortions | Particles, scratches, pits, crystal defects |

| Equipment Complexity | High, requires advanced imaging and analysis | Moderate, simpler optics and surface analysis |

| Inspection Speed | Slower due to detailed pattern analysis | Faster due to simpler surface inspection |

| Typical Use Case | Post-lithography process verification | Incoming wafer quality control |

| Data Output | Defect maps correlated to circuit layout | Surface defect counts and characterization |

Introduction to Wafer Inspection

Wafer inspection is a critical process in semiconductor manufacturing that ensures the quality and functionality of wafers before device fabrication. Patterned wafer inspection targets defects on wafers with circuit patterns already etched, requiring high-precision imaging to detect micro-scale errors affecting chip performance. Bare wafer inspection focuses on the substrate's surface quality, identifying contaminants and surface anomalies that could compromise subsequent lithography steps, helping maintain your production yield and device reliability.

What is Bare Wafer Inspection?

Bare wafer inspection is a critical process in semiconductor manufacturing that involves examining unprocessed or lightly processed silicon wafers to detect surface defects, contamination, and structural irregularities. This inspection ensures the wafer's quality before further patterning steps, using advanced optical and electron microscopy techniques for precise defect identification. Compared to patterned wafer inspection, which analyzes processed wafers with circuit patterns, bare wafer inspection focuses on the wafer's foundational integrity to prevent defects from propagating in later fabrication stages.

What is Patterned Wafer Inspection?

Patterned wafer inspection involves examining semiconductor wafers with pre-existing circuit patterns to detect defects such as pattern deviations, particles, and process-induced flaws. This inspection uses advanced optical or electron beam techniques to identify discrepancies that can impact device performance and yield. Patterned wafer inspection is critical for ensuring the integrity of complex microelectronic circuits before further processing or packaging.

Key Differences Between Patterned and Bare Wafer Inspection

Patterned wafer inspection targets defects in integrated circuit patterns such as line breaks, shorts, and CD (critical dimension) variations, utilizing advanced imaging techniques like SEM and optical microscopy tailored for complex geometries. Bare wafer inspection primarily detects surface contamination, particles, and crystal defects, relying on tools such as surface scanners and laser scattering for clean silicon substrates. The key difference lies in the inspection goals: patterned wafer inspection focuses on circuit integrity and pattern fidelity, while bare wafer inspection ensures substrate quality prior to circuit fabrication.

Inspection Techniques for Bare Wafers

Inspection techniques for bare wafers predominantly utilize advanced optical methods such as brightfield and darkfield microscopy to detect surface defects and contamination at high resolution. Techniques like laser scattering and infrared inspection enable non-destructive analysis of wafer uniformity and subsurface anomalies, ensuring optimal yield in semiconductor manufacturing. Your choice of inspection method directly impacts defect detection sensitivity and process control accuracy in bare wafer evaluation.

Inspection Techniques for Patterned Wafers

Patterned wafer inspection employs advanced optical and electron beam techniques to detect defects within intricate circuit patterns, ensuring high-resolution analysis of micro-scale features. Techniques such as defect review systems utilize high-magnification imaging and sophisticated algorithms to identify anomalies in pattern geometry and overlay accuracy. Your manufacturing process benefits from these precise inspection methods by reducing pattern-related defects and enhancing overall device yield.

Challenges in Bare Wafer Inspection

Bare wafer inspection presents significant challenges such as detecting ultra-fine defects on smooth, reflective surfaces that lack prominent patterns for reference, making automated defect recognition difficult. The absence of patterned features requires advanced imaging techniques like dark-field or laser scattering methods to identify sub-micron particles or micro-scratches. High sensitivity to surface contamination and wafer flatness variations further complicates accurate defect isolation compared to patterned wafer inspection where pattern consistency aids defect differentiation.

Challenges in Patterned Wafer Inspection

Patterned wafer inspection faces complex challenges such as detecting subtle defects amidst intricate circuit designs, which increase the difficulty of distinguishing true flaws from acceptable variations. Advanced algorithms and high-resolution imaging techniques are essential to accurately identify pattern-specific anomalies without generating excessive false positives. Improving these inspection processes ensures your semiconductor manufacturing yields higher reliability and performance.

Applications in Semiconductor Manufacturing

Patterned wafer inspection targets defects in fabricated layers such as photoresist, etching, and metallization, essential for identifying critical circuit pattern flaws in advanced semiconductor devices. Bare wafer inspection focuses on detecting surface contamination, crystal defects, and particles on unprocessed wafers, crucial for ensuring substrate quality before fabrication. Both inspection types are vital in semiconductor manufacturing, with patterned inspection ensuring device functionality and bare wafer inspection preventing downstream process failures.

Choosing the Right Wafer Inspection Method

Choosing the right wafer inspection method depends on the specific challenges of your manufacturing process, where patterned wafer inspection targets critical defects on complex circuit designs, while bare wafer inspection focuses on surface defects before patterning. Patterned wafer inspection offers high-resolution defect detection essential for advanced semiconductor nodes, enhancing yield by identifying photolithography and etching errors. Bare wafer inspection provides early process feedback by detecting contaminants and surface anomalies, enabling process optimization before costly patterning steps.

Patterned Wafer Inspection vs Bare Wafer Inspection Infographic

libmatt.com

libmatt.com