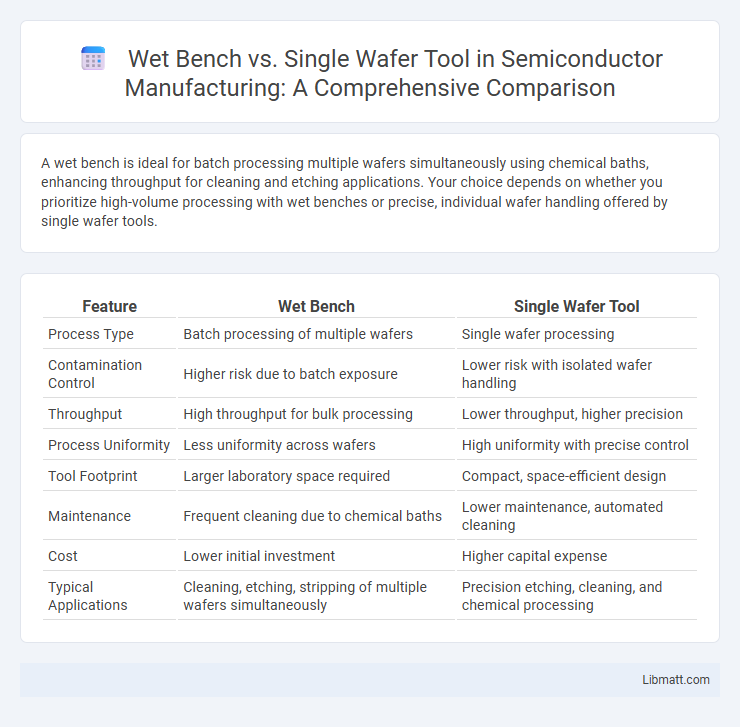

A wet bench is ideal for batch processing multiple wafers simultaneously using chemical baths, enhancing throughput for cleaning and etching applications. Your choice depends on whether you prioritize high-volume processing with wet benches or precise, individual wafer handling offered by single wafer tools.

Table of Comparison

| Feature | Wet Bench | Single Wafer Tool |

|---|---|---|

| Process Type | Batch processing of multiple wafers | Single wafer processing |

| Contamination Control | Higher risk due to batch exposure | Lower risk with isolated wafer handling |

| Throughput | High throughput for bulk processing | Lower throughput, higher precision |

| Process Uniformity | Less uniformity across wafers | High uniformity with precise control |

| Tool Footprint | Larger laboratory space required | Compact, space-efficient design |

| Maintenance | Frequent cleaning due to chemical baths | Lower maintenance, automated cleaning |

| Cost | Lower initial investment | Higher capital expense |

| Typical Applications | Cleaning, etching, stripping of multiple wafers simultaneously | Precision etching, cleaning, and chemical processing |

Introduction to Wet Bench and Single Wafer Tool Technologies

Wet bench technology utilizes bulk liquid chemical processing for simultaneous treatment of multiple wafers, enabling efficient etching, cleaning, and rinsing in semiconductor fabrication. Single wafer tools process wafers individually through automated, controlled environments, offering higher precision and reduced cross-contamination. Both technologies play critical roles in semiconductor manufacturing, with wet benches suited for high-throughput batch processing and single wafer tools optimized for advanced node demands and process control.

Key Differences Between Wet Bench and Single Wafer Processing

Wet bench processing involves the use of chemical baths for wafer cleaning, etching, or stripping, typically handling multiple wafers simultaneously in a batch mode, which enhances throughput but may increase contamination risk. Single wafer tools operate on individual wafers with precise control over process parameters, offering higher uniformity, reduced cross-contamination, and better integration with automated semiconductor fabrication lines. Key differences include process scale (batch vs. single), contamination control, and precision, impacting yield and suitability for advanced semiconductor nodes.

Process Workflow: Wet Bench vs Single Wafer Tool

Wet bench process workflows involve batch processing of multiple wafers immersed in chemical baths, enabling simultaneous treatment but requiring careful handling to avoid cross-contamination. Single wafer tools process each wafer independently, offering precise control over individual wafer exposure and uniformity, which improves yield and reduces variability. Your choice between these workflows impacts throughput, process control, and contamination risk, crucial for optimizing semiconductor fabrication efficiency.

Advantages of Wet Bench Systems

Wet bench systems offer superior chemical process flexibility and scalability, accommodating large batch processing with high throughput efficiency. They enable precise control over etching, cleaning, and rinsing stages, minimizing contamination risks in semiconductor fabrication. Cost-effectiveness and ease of maintenance further enhance their suitability for diverse wet processing applications.

Benefits of Single Wafer Processing Tools

Single wafer processing tools offer enhanced precision and uniformity by handling each wafer individually, reducing the risk of cross-contamination and improving yield consistency. These tools enable faster turnaround times and greater flexibility, allowing customization of processes for each wafer to meet specific requirements. Your semiconductor manufacturing efficiency benefits from increased control and scalability inherent in single wafer systems compared to traditional wet bench operations.

Application Areas for Wet Bench and Single Wafer Tools

Wet bench tools excel in chemical etching, cleaning, and resist stripping for semiconductor wafers in research labs and high-volume manufacturing of microelectronics, MEMS, and photovoltaics. Single wafer tools provide precise and uniform chemical processing, ideal for advanced semiconductor device fabrication, including front-end wafer cleaning, surface modification, and photoresist development. Both systems support critical processes but differ in throughput and process control, impacting their suitability for specific application areas.

Throughput and Yield Considerations

Wet bench systems offer higher throughput for batch processing, making them efficient for large wafer volumes, while single wafer tools provide better yield control through precise processing on individual wafers. Single wafer tools reduce contamination risks and enable tighter process control, which can enhance yield in semiconductor manufacturing. Your choice should weigh the trade-off between throughput efficiency and yield optimization based on production scale and quality requirements.

Cost Implications and ROI Analysis

Wet benches typically involve lower upfront capital investment compared to single wafer tools, making them more accessible for smaller production volumes. Single wafer tools offer higher throughput and more precise process control, driving greater long-term efficiency and yield improvements that can justify their higher initial costs. ROI analysis often favors single wafer tools in high-volume manufacturing due to reduced chemical usage and improved wafer uniformity, while wet benches may yield quicker payback periods in smaller or R&D environments.

Contamination Control and Cleanroom Requirements

Wet bench systems provide superior contamination control by using liquid-based processes that minimize particle generation and enable effective chemical management, essential for high-purity semiconductor manufacturing. Single wafer tools offer enhanced cleanroom integration with smaller footprints and localized airflow control, reducing cross-contamination risk between wafers. Strict cleanroom classifications such as ISO 5 or better are typically required for both systems, but wet benches demand more rigorous chemical handling protocols to maintain contamination-free environments.

Choosing the Right Tool for Semiconductor Manufacturing

Selecting between a Wet Bench and a Single Wafer Tool depends on the specific semiconductor manufacturing process requirements, including throughput, precision, and contamination control. Wet Benches excel in batch processing for etching and cleaning multiple wafers simultaneously, offering cost efficiency for high-volume production. Your choice should align with production goals: Single Wafer Tools provide superior uniformity and process control for advanced nodes, while Wet Benches suit large-scale, less complex processes.

Wet Bench vs Single Wafer Tool Infographic

libmatt.com

libmatt.com