Air riveters deliver higher power and speed for heavy-duty rivet installation, making them ideal for industrial or automotive projects. Your choice depends on whether you prioritize portability and precision offered by hand riveters or the efficiency and consistency of air riveters for large-scale tasks.

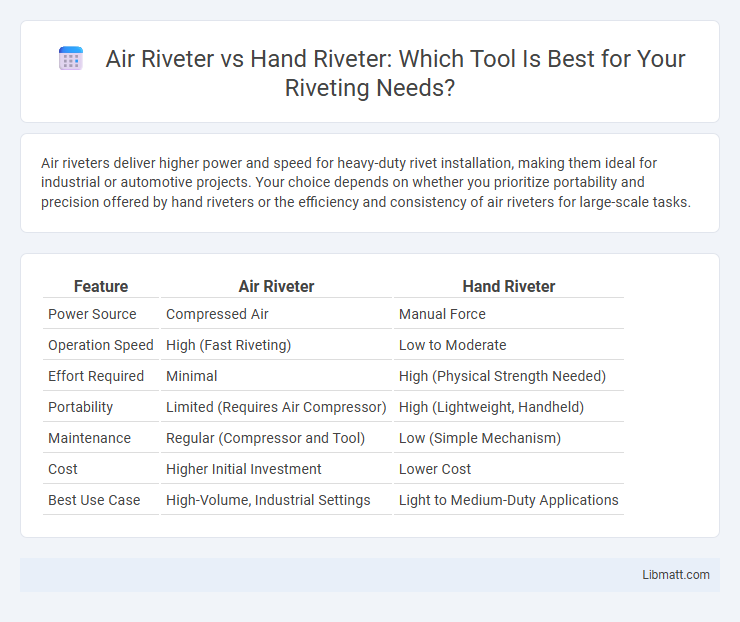

Table of Comparison

| Feature | Air Riveter | Hand Riveter |

|---|---|---|

| Power Source | Compressed Air | Manual Force |

| Operation Speed | High (Fast Riveting) | Low to Moderate |

| Effort Required | Minimal | High (Physical Strength Needed) |

| Portability | Limited (Requires Air Compressor) | High (Lightweight, Handheld) |

| Maintenance | Regular (Compressor and Tool) | Low (Simple Mechanism) |

| Cost | Higher Initial Investment | Lower Cost |

| Best Use Case | High-Volume, Industrial Settings | Light to Medium-Duty Applications |

Introduction to Riveting Tools

Air riveters deliver rapid, consistent fastening power ideal for large-scale industrial projects, while hand riveters offer greater control and portability suited for smaller tasks or detailed work. Both tools are essential in joining metal sheets, with the air riveter using compressed air for efficiency and the hand riveter relying on manual force for precision. Your choice depends on the volume and intricacy of riveting required, balancing speed against maneuverability.

What is an Air Riveter?

An air riveter is a pneumatic tool that uses compressed air to drive rivets quickly and with consistent force, ideal for heavy-duty or high-volume riveting tasks. Unlike a hand riveter, which requires manual effort, an air riveter reduces fatigue and increases precision, making it suitable for professional use in automotive or aerospace industries. You can achieve faster assembly times and stronger, more reliable joints with an air riveter compared to traditional hand-operated models.

What is a Hand Riveter?

A hand riveter is a manual tool designed for fastening metal or other materials by driving rivets through aligned holes. It offers portability and precision, making it ideal for smaller projects or areas with limited access where you require control and ease of use. Unlike air riveters, which rely on compressed air for power, a hand riveter operates solely through hand pressure, allowing for greater versatility in tasks without the need for external power sources.

Key Differences Between Air Riveter and Hand Riveter

Air riveters operate using compressed air, providing faster and more consistent riveting with less physical effort compared to hand riveters, which rely solely on manual force. Hand riveters offer greater portability and are ideal for small-scale or precision tasks, while air riveters excel in high-volume industrial applications due to their speed and efficiency. Your choice depends on the project scale, with air riveters suited for repetitive, heavy-duty jobs and hand riveters preferred for lighter or occasional use.

Efficiency and Speed Comparison

Air riveters significantly outperform hand riveters in efficiency and speed, delivering faster and more consistent rivet installation due to their pneumatic power. While hand riveters require manual force and more time per rivet, air riveters can operate continuously without fatigue, making them ideal for high-volume or industrial applications. Your production process benefits from reduced assembly time and increased throughput when using air riveters over traditional hand-operated tools.

Ease of Use and Ergonomics

Air riveters offer superior ease of use by requiring less physical effort through pneumatic power, reducing user fatigue during repetitive tasks. Hand riveters demand more manual strength and can cause strain over extended periods, making them less ergonomic for frequent or heavy-duty applications. Ergonomic design in air riveters often includes lightweight bodies and comfortable grips, enhancing user comfort and efficiency.

Cost Analysis: Upfront and Maintenance

Air riveters typically require a higher upfront investment, often ranging from $150 to $500, compared to hand riveters which cost between $10 and $50. Maintenance expenses for air riveters include air compressor servicing, lubrication, and occasional part replacements, leading to increased long-term costs, whereas hand riveters have minimal maintenance primarily limited to cleaning and occasional jaw replacements. Businesses should weigh the initial purchasing cost against ongoing maintenance when choosing between air and hand riveters for budget efficiency.

Ideal Applications for Air Riveters

Air riveters are ideal for high-volume manufacturing and automotive assembly where consistent, strong rivet installation is critical. They excel in aerospace and metal fabrication industries due to their ability to deliver powerful, fast, and precise riveting with minimal operator fatigue. Their pneumatic mechanism allows for repetitive, heavy-duty use, which surpasses the capabilities of manual hand riveters in both speed and efficiency.

Ideal Applications for Hand Riveters

Hand riveters are ideal for light-duty applications such as small repairs, hobby projects, and assembling thin materials like aluminum or plastic. Their portability and ease of use make them perfect for tasks in tight spaces or where power sources are unavailable. They are commonly used in automotive, electronics, and home improvement projects requiring precision and low volume riveting.

Choosing the Right Riveter for Your Needs

Choosing the right riveter depends on the scale and precision of your projects; air riveters provide faster, more consistent riveting ideal for industrial or heavy-duty use, while hand riveters offer greater portability and control for smaller tasks or occasional repairs. Air riveters require a compressor and more setup, making them better suited for frequent, large-scale operations, whereas hand riveters are cost-effective and convenient for DIY enthusiasts or light assembly work. Evaluating the volume, material thickness, and working environment will guide you to the optimal riveter type for efficiency and quality outcomes.

Air riveter vs hand riveter Infographic

libmatt.com

libmatt.com