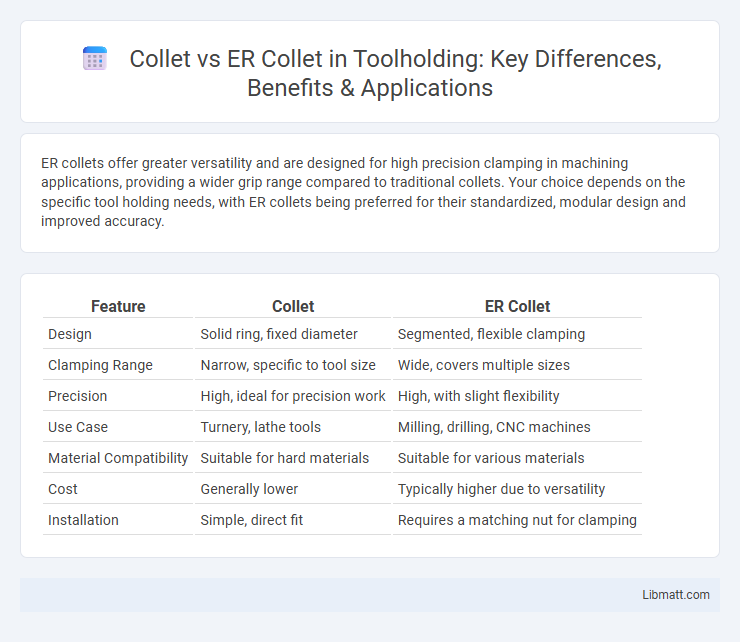

ER collets offer greater versatility and are designed for high precision clamping in machining applications, providing a wider grip range compared to traditional collets. Your choice depends on the specific tool holding needs, with ER collets being preferred for their standardized, modular design and improved accuracy.

Table of Comparison

| Feature | Collet | ER Collet |

|---|---|---|

| Design | Solid ring, fixed diameter | Segmented, flexible clamping |

| Clamping Range | Narrow, specific to tool size | Wide, covers multiple sizes |

| Precision | High, ideal for precision work | High, with slight flexibility |

| Use Case | Turnery, lathe tools | Milling, drilling, CNC machines |

| Material Compatibility | Suitable for hard materials | Suitable for various materials |

| Cost | Generally lower | Typically higher due to versatility |

| Installation | Simple, direct fit | Requires a matching nut for clamping |

Introduction to Collets and ER Collets

Collets are precision tool holders designed to securely clamp cylindrical workpieces or cutting tools by applying uniform radial pressure. ER collets, a popular subtype, feature a versatile, split design that allows them to accommodate a range of tool shank sizes within a defined range, providing high concentric accuracy and strong gripping force. Understanding the difference between general collets and ER collets helps you select the optimal tool holder for machining tasks requiring precision and adaptability.

What Is a Standard Collet?

A standard collet, often referred to simply as a collet, is a cylindrical sleeve used to hold cutting tools or workpieces securely in place during machining operations. Unlike ER collets, which feature a segmented design for uniform clamping and flexibility across various tool sizes, a standard collet typically provides a tight grip for a specific shaft diameter, ensuring precision and stability. Standard collets are commonly utilized in applications requiring high concentricity and rigidity, such as milling, drilling, and lathe work.

Understanding ER Collets

ER collets provide superior clamping precision compared to traditional Collet systems by offering a wider clamping range and better tension distribution. ER collets maintain high concentricity, essential for machining accuracy, due to their standardized design with multiple slits allowing uniform compression around the tool shank. The versatility and consistent grip make ER collets the preferred choice in CNC machining and high-precision tooling applications.

Key Differences: Collet vs ER Collet

Key differences between a traditional Collet and an ER Collet include design, clamping range, and versatility. ER Collets feature a slotted cylindrical shape allowing for a wider clamping range and higher precision in tool holding, while traditional Collets offer limited size options and are primarily suited for specific tools. Your choice should consider application demands, with ER Collets excelling in flexibility and consistent gripping of various tool sizes.

Accuracy and Clamping Force Comparison

Collets like the Collet and ER collet systems excel in providing precise tool holding with high accuracy levels, but ER collets generally offer superior clamping force due to their tapered design and flexible segments. The ER collet's design allows for a wider clamping range, accommodating varying tool diameters while maintaining consistent accuracy, making it ideal for demanding machining tasks. Compared to standard collets, ER collets deliver enhanced grip and reduced runout, which significantly improves machining precision and stability.

Versatility and Tool Compatibility

Collets, including ER collets, excel in tool holding versatility but differ in compatibility and application. Standard collets are designed for specific tool shank sizes and shapes, offering precise gripping primarily with round or hexagonal tools, while ER collets accommodate a broader range of tool diameters within their clamping range, enhancing adaptability for various cutting tools. ER collets provide superior versatility for milling, drilling, and turning operations due to their standardized system and ability to hold multiple tool sizes securely in one collet series.

Ease of Use and Tool Change

Collets designed as ER collets provide superior ease of use and faster tool changes compared to traditional Collets due to their standardized size system and flexible clamping range. The ER collet system allows for quick tool swapping with minimal adjustments, reducing downtime in machining operations. In contrast, conventional Collets often require more manual effort and precise matching to tool shank sizes, leading to longer changeover times.

Applications in Various Industries

Collet and ER collet systems are essential for precise tool holding across manufacturing, aerospace, and automotive industries due to their high accuracy and strong gripping force. ER collets offer versatility in clamping different shank sizes, making them ideal for CNC machining, milling, and drilling applications, where adaptability and precision are critical. You can enhance productivity by selecting the appropriate collet type based on the specific machining requirements and industry standards.

Cost Considerations: Collet vs ER Collet

Collets generally offer a lower initial cost compared to ER collets, making them a budget-friendly option for basic clamping needs. ER collets, while more expensive upfront, provide greater versatility and precision, which can reduce tooling changes and improve overall efficiency in machining operations. Investing in ER collets can lead to long-term cost savings due to their adaptability across a wider range of tool sizes and enhanced holding accuracy.

Which One to Choose for Your Needs?

Choosing between a Collet and an ER Collet depends on the precision and versatility required for your machining tasks. ER collets offer superior clamping force and accommodate a broader range of tool sizes, making them ideal for high-precision and heavy-duty applications. Standard collets provide reliable performance for specific tool sizes and simpler setups, suited for less demanding operations or when cost-efficiency is a priority.

Collet vs ER collet Infographic

libmatt.com

libmatt.com