Slab mills are designed for heavy material removal and large-scale surface flattening, making them ideal for roughing operations on thick slabs and plates. Face mills provide a smoother finish and greater precision on flat surfaces, perfect for your finishing and contouring tasks on smaller or more detailed workpieces.

Table of Comparison

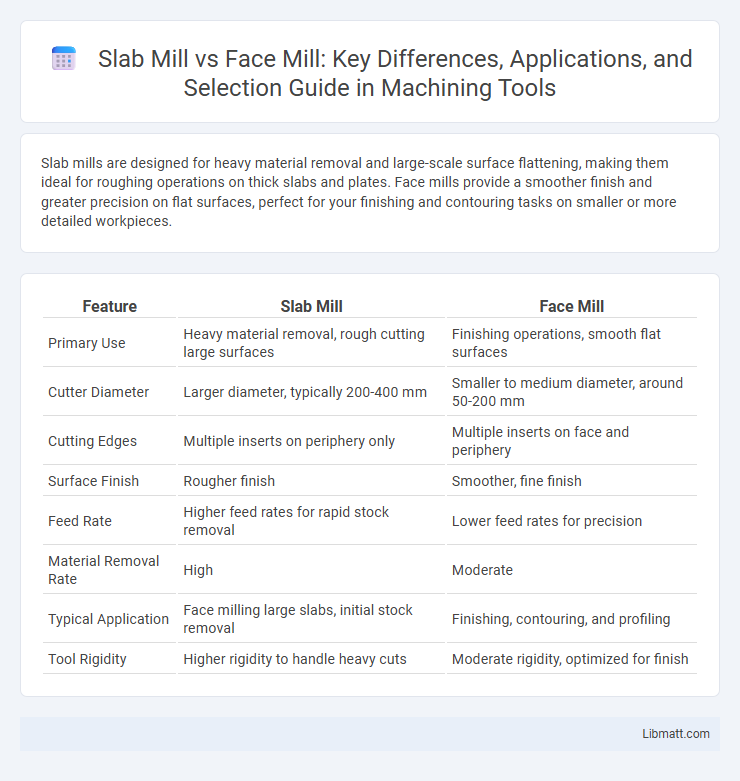

| Feature | Slab Mill | Face Mill |

|---|---|---|

| Primary Use | Heavy material removal, rough cutting large surfaces | Finishing operations, smooth flat surfaces |

| Cutter Diameter | Larger diameter, typically 200-400 mm | Smaller to medium diameter, around 50-200 mm |

| Cutting Edges | Multiple inserts on periphery only | Multiple inserts on face and periphery |

| Surface Finish | Rougher finish | Smoother, fine finish |

| Feed Rate | Higher feed rates for rapid stock removal | Lower feed rates for precision |

| Material Removal Rate | High | Moderate |

| Typical Application | Face milling large slabs, initial stock removal | Finishing, contouring, and profiling |

| Tool Rigidity | Higher rigidity to handle heavy cuts | Moderate rigidity, optimized for finish |

Introduction to Slab Mill and Face Mill

Slab mills are heavy-duty cutting tools designed primarily for roughing operations on large metal surfaces, delivering high material removal rates with robust durability. Face mills, by contrast, are versatile milling cutters optimized for finishing and producing smooth, flat surfaces with precision and fine surface finish. Your choice between slab mill and face mill depends on the specific machining requirements, such as the desired surface finish and the extent of material removal needed.

Key Differences Between Slab Milling and Face Milling

Slab milling involves removing large amounts of material using a cutter with multiple teeth mounted on a horizontal arbor, making it ideal for machining wide surfaces and heavy cuts. Face milling uses a cutter mounted on a vertical arbor to produce flat surfaces with a smoother finish, focusing on the cutter's end teeth for material removal. Understanding these key differences helps you select the appropriate milling process based on surface area, finish quality, and material removal rate.

Overview of Slab Milling Technique

Slab milling is a machining process that uses a multi-toothed cutter to remove large amounts of material from flat surfaces, typically on steel billets or large metal blocks. This technique features a horizontal spindle with a wide cutter, allowing for efficient, high-volume material removal and a smoother surface finish compared to face milling. Slab milling is ideal for heavy-duty applications requiring deep cuts and extensive metal removal.

Overview of Face Milling Technique

Face milling is a machining process that removes material from a workpiece surface using a rotating cutter with multiple cutting edges positioned at the end of the tool. This technique excels in producing flat, smooth surfaces with excellent dimensional accuracy and is commonly used for large, flat areas in metalworking. Your choice between a slab mill and a face mill depends on the desired surface finish, material removal rate, and the specific application requirements.

Tool Design: Slab Mill vs Face Mill

Slab mills feature larger diameter and multiple inserts arranged on the periphery, designed for heavy roughing and maximum material removal on large surfaces. Face mills have a smaller diameter with inserts primarily on the face, optimized for producing smooth finishes and precise dimensions on flat surfaces. Your choice between slab mill vs face mill depends on the desired balance of cutting speed, surface finish, and depth of cut in your machining operation.

Material Removal Capabilities

Slab mills excel in high-volume material removal with their multiple cutting edges designed for roughing large steel slabs, offering greater depth of cut and feed rates compared to face mills. Face mills prioritize precision and surface finish with fewer cutting edges, ideal for finishing operations requiring smooth surfaces and tight tolerances. Your choice depends on whether maximizing material removal or achieving fine surface quality is the primary goal.

Surface Finish Comparison

Surface finish comparison between slab mills and face mills reveals key differences in machining outcomes. Face mills typically produce smoother, finer finishes due to their multiple cutting edges and higher rotational speeds, making them ideal for precision surfaces. Slab mills, designed for heavy material removal with fewer cutting edges, result in coarser finishes, which may require secondary operations to achieve the desired surface quality on Your workpiece.

Typical Applications for Each Milling Method

Slab mills are primarily used for removing large amounts of material quickly from flat surfaces on heavy workpieces, making them ideal for roughing operations in steel manufacturing and large component machining. Face mills excel in producing smooth, precise finishes on flat surfaces, often utilized in finishing operations for automotive parts, aerospace components, and mold-making. The choice between slab mill and face mill depends on the required surface finish, material removal rate, and workpiece size.

Advantages and Disadvantages

Slab mills offer high material removal rates and are ideal for heavy-duty, roughing operations on large workpieces, but they tend to be less precise and generate more vibration compared to face mills. Face mills provide superior surface finish and dimensional accuracy, making them suitable for finishing and lighter cutting tasks, though they generally have lower material removal rates and may wear out faster in tough conditions. Choosing between slab mill and face mill depends on balancing the need for speed and roughing capacity versus precision and surface quality.

Choosing the Right Milling Tool for Your Project

When choosing the right milling tool for your project, consider that slab mills are ideal for heavy-duty, high-volume material removal on large, flat surfaces due to their multiple cutting edges and large diameter. Face mills offer greater precision and surface finish quality, making them suitable for detailed work and finishing passes on smaller or irregular surfaces. Your decision should balance the desired surface finish, material type, and machining efficiency to optimize performance and cost-effectiveness.

Slab mill vs face mill Infographic

libmatt.com

libmatt.com