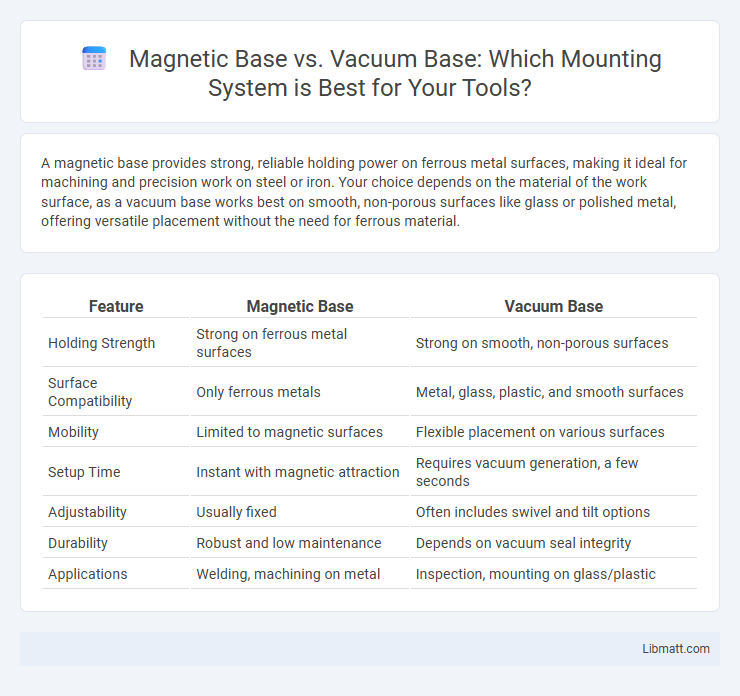

A magnetic base provides strong, reliable holding power on ferrous metal surfaces, making it ideal for machining and precision work on steel or iron. Your choice depends on the material of the work surface, as a vacuum base works best on smooth, non-porous surfaces like glass or polished metal, offering versatile placement without the need for ferrous material.

Table of Comparison

| Feature | Magnetic Base | Vacuum Base |

|---|---|---|

| Holding Strength | Strong on ferrous metal surfaces | Strong on smooth, non-porous surfaces |

| Surface Compatibility | Only ferrous metals | Metal, glass, plastic, and smooth surfaces |

| Mobility | Limited to magnetic surfaces | Flexible placement on various surfaces |

| Setup Time | Instant with magnetic attraction | Requires vacuum generation, a few seconds |

| Adjustability | Usually fixed | Often includes swivel and tilt options |

| Durability | Robust and low maintenance | Depends on vacuum seal integrity |

| Applications | Welding, machining on metal | Inspection, mounting on glass/plastic |

Introduction to Magnetic Base and Vacuum Base

Magnetic bases use strong magnets to securely attach tools or devices to ferromagnetic surfaces, providing a stable platform for precision work such as machining or inspection. Vacuum bases create a strong suction force to adhere to smooth, non-porous surfaces, making them ideal for flexible placement on glass, polished metal, or plastic without relying on magnetic properties. Understanding your work environment and surface material will help you choose between a magnetic base for metal surfaces or a vacuum base for non-metal, smooth areas.

How Magnetic Bases Work

Magnetic bases create a strong, consistent holding force by using permanent magnets or electromagnets that generate a magnetic field to securely attach tools or devices to ferrous metal surfaces. The magnetic flux passes through the base and the metal surface, providing stability and precision for measurement tools, welding, or machining operations. Your equipment remains firmly in place as long as the magnet is engaged, making magnetic bases ideal for setups on steel or iron surfaces.

How Vacuum Bases Function

Vacuum bases create a strong seal on smooth, non-porous surfaces by removing air to generate suction, allowing for secure attachment without the need for metal surfaces. They function through a vacuum pump or manual lever that evacuates air, producing negative pressure which holds the base firmly in place. This suction mechanism enables vacuum bases to operate effectively on glass, plastic, or painted steel, providing versatility beyond the magnetic base's reliance on ferromagnetic materials.

Application Areas for Magnetic Bases

Magnetic bases are extensively used in machining, metalworking, and inspection industries due to their strong hold on ferrous surfaces, enabling precise positioning of dial indicators and other measuring instruments. These bases are ideal for applications requiring a stable and reusable mount on steel or iron machinery, enhancing measurement accuracy in tool setups and quality control processes. Their magnetic properties limit use on non-metallic or non-ferrous materials, where vacuum bases offer better adaptability.

Application Areas for Vacuum Bases

Vacuum bases are commonly used in applications requiring temporary, non-marring attachment to smooth, non-ferrous surfaces such as glass, polished metals, and plastics. Industries like automotive manufacturing, electronics assembly, and laboratory equipment frequently utilize vacuum bases to securely hold instruments and fixtures without damaging delicate surfaces. Their versatility makes them ideal for precision work on surfaces where magnetic bases are ineffective due to material composition.

Strengths of Magnetic Bases

Magnetic bases offer superior holding power on ferrous metal surfaces, providing a reliable and stable attachment for precision tools and measuring instruments. Their strength lies in consistent magnetic force without the need for external power sources, ensuring durability and long-term usability. Magnetic bases excel in industrial environments where strong, vibration-resistant fixtures are essential for accurate measurements and machining operations.

Strengths of Vacuum Bases

Vacuum bases offer superior versatility by securely attaching to a wide range of smooth, non-metallic surfaces, making them ideal for delicate or irregular materials where magnetic bases fail. They provide strong, consistent holding power without requiring ferromagnetic substrates, enhancing stability in precision measuring, inspection, and welding applications. The ability to quickly engage and release vacuum suction improves setup efficiency and reduces surface damage compared to magnetic bases.

Limitations of Magnetic Bases

Magnetic bases are limited by their dependence on ferromagnetic surfaces, rendering them ineffective on non-metallic or non-ferrous materials such as aluminum or plastic. They often require a flat, clean surface for optimal adhesion, and their holding force can diminish when exposed to vibrations or uneven surfaces. In contrast, vacuum bases offer versatile attachment to various smooth surfaces but may struggle with porous or textured materials.

Limitations of Vacuum Bases

Vacuum bases have limitations such as reduced holding power on porous or uneven surfaces, making them less reliable for securing tools or instruments on materials like wood or rough metal. They also require a smooth, non-porous surface to maintain a strong vacuum seal, which restricts their usability in diverse environments. You should consider these constraints when choosing between vacuum and magnetic bases for your application.

Magnetic Base vs Vacuum Base: Which One Should You Choose?

Magnetic bases offer strong adhesion on ferrous metal surfaces, making them ideal for machining, welding, and inspection tasks where stability is crucial. Vacuum bases provide versatile mounting on smooth, non-metal surfaces like glass or polished stone, offering portability and ease of setup in environments where metal surfaces are unavailable. Choosing between magnetic and vacuum bases depends on the surface material, required holding strength, and application-specific mobility needs.

Magnetic base vs vacuum base Infographic

libmatt.com

libmatt.com