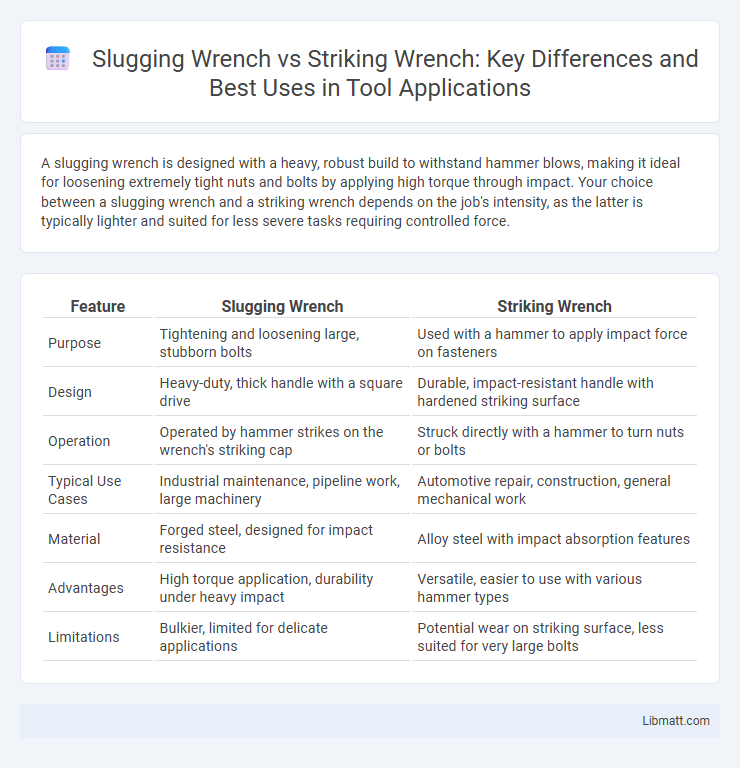

A slugging wrench is designed with a heavy, robust build to withstand hammer blows, making it ideal for loosening extremely tight nuts and bolts by applying high torque through impact. Your choice between a slugging wrench and a striking wrench depends on the job's intensity, as the latter is typically lighter and suited for less severe tasks requiring controlled force.

Table of Comparison

| Feature | Slugging Wrench | Striking Wrench |

|---|---|---|

| Purpose | Tightening and loosening large, stubborn bolts | Used with a hammer to apply impact force on fasteners |

| Design | Heavy-duty, thick handle with a square drive | Durable, impact-resistant handle with hardened striking surface |

| Operation | Operated by hammer strikes on the wrench's striking cap | Struck directly with a hammer to turn nuts or bolts |

| Typical Use Cases | Industrial maintenance, pipeline work, large machinery | Automotive repair, construction, general mechanical work |

| Material | Forged steel, designed for impact resistance | Alloy steel with impact absorption features |

| Advantages | High torque application, durability under heavy impact | Versatile, easier to use with various hammer types |

| Limitations | Bulkier, limited for delicate applications | Potential wear on striking surface, less suited for very large bolts |

Introduction to Slugging Wrench vs Striking Wrench

A slugging wrench is designed with a heavy-duty handle allowing you to apply force by striking it with a hammer, making it ideal for loosening stubborn or rusted bolts in industrial settings. In contrast, a striking wrench features a reinforced head specifically engineered to withstand repeated hammer blows, providing durability during heavy impact applications. Understanding the differences between slugging and striking wrenches ensures you choose the right tool for your maintenance or construction tasks, enhancing efficiency and safety.

What is a Slugging Wrench?

A slugging wrench is a heavy-duty hand tool designed to tighten or loosen large nuts and bolts using a hammer or mallet to deliver powerful striking force. Unlike a striking wrench, which typically incorporates shock-absorbing features to reduce user fatigue, a slugging wrench relies on the impact energy transferred directly from the hammer. You should choose a slugging wrench for tasks requiring maximum torque in industrial or construction settings where precision impact is less critical.

What is a Striking Wrench?

A striking wrench is a heavy-duty hand tool designed for use with a hammer or mallet to apply high-impact force to loosen or tighten stubborn fasteners. Unlike standard wrenches, it features a robust, reinforced body and often has a flat or slightly rounded striking surface to withstand repeated hammer blows. This tool is ideal for heavy maintenance tasks where bolts and nuts are rusted or over-torqued.

Key Differences Between Slugging and Striking Wrenches

Slugging wrenches feature a robust, solid handle designed to withstand heavy hammer impacts for loosening stubborn bolts, while striking wrenches incorporate shock-absorbing handles to reduce user fatigue during repetitive hammer strikes. The primary difference lies in their handle construction and intended use: slugging wrenches rely on blunt force through the handle and head, whereas striking wrenches are engineered to minimize vibration transmission. Material durability and ergonomic design also distinguish the two, with slugging wrenches favoring maximum impact resistance and striking wrenches balancing strength and user comfort.

Common Applications of Slugging Wrenches

Slugging wrenches are primarily used in heavy industrial settings, such as construction, mining, and oil and gas industries, where high torque is required to loosen or tighten large nuts and bolts. Your maintenance or operations team will find slugging wrenches ideal for working with large fasteners on machinery, pipelines, and structural steel. These wrenches are designed to withstand impacts from a hammer, making them suitable for applications involving stubborn or rusted fasteners.

Typical Uses of Striking Wrenches

Striking wrenches are primarily used in heavy-duty applications such as loosening or tightening large nuts and bolts on construction machinery, industrial equipment, and automotive assemblies. Their robust design allows them to withstand impact forces from hammers, making them ideal for tasks requiring high torque and force. These wrenches are commonly employed in mining, manufacturing, and maintenance operations where precision and durability are critical.

Pros and Cons of Slugging Wrenches

Slugging wrenches provide high torque through impact force via a hammer strike, making them ideal for loosening tightly fastened bolts and nuts but require significant operator skill to avoid damage. The design allows for heavy-duty applications in construction and industrial maintenance, though the need for additional tools like a hammer and the risk of injury or tool wear are notable drawbacks. Compared to striking wrenches, slugging wrenches offer precise control over torque application but are less versatile and slower for repetitive fastening tasks.

Advantages and Disadvantages of Striking Wrenches

Striking wrenches offer the advantage of delivering high torque through impact, making them ideal for loosening stubborn or rusted bolts quickly. However, their heavy design can lead to hand fatigue and requires careful handling to avoid damage to surrounding components. Your choice depends on the balance between raw power needs and the precision required for the task.

How to Choose Between Slugging and Striking Wrenches

Choosing between a slugging wrench and a striking wrench depends on the application requirements and safety considerations. Slugging wrenches are designed for heavy-duty tasks where you strike the wrench directly with a hammer, providing high torque for loosening stubborn fasteners, while striking wrenches typically handle lighter impacts with tools like impact hammers or mallets. Your selection should prioritize the type of fastener, the force needed, and the compatibility with your available tools for optimal performance and safety.

Safety Tips for Using Slugging and Striking Wrenches

When using slugging and striking wrenches, always wear appropriate personal protective equipment such as safety goggles and gloves to prevent injuries from flying debris or accidental strikes. Ensure your wrench is in good condition, with no cracks or excessive wear, and never use a wrench as a hammer unless it is specifically designed for striking. Maintain proper grip and posture to reduce the risk of slipping or losing control, protecting your safety and the effectiveness of your work.

Slugging wrench vs striking wrench Infographic

libmatt.com

libmatt.com