Slip rolls offer precise bending of metal sheets by relying on friction, making them ideal for delicate curves and smaller projects, while plate rolls are designed for heavier, thicker materials to create larger cylindrical shapes efficiently. Understanding your project's material thickness and desired curvature helps determine whether a slip roll or plate roll best suits your metal forming needs.

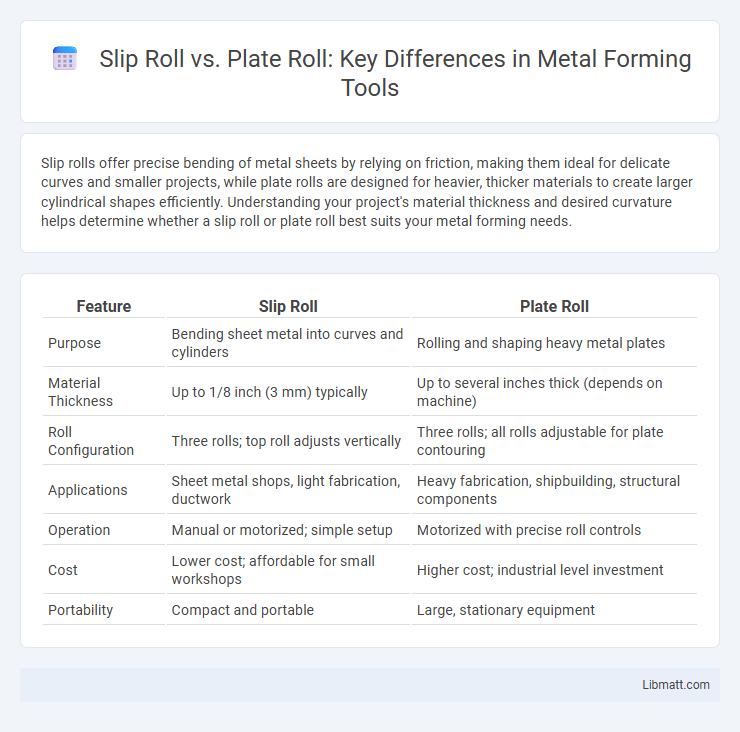

Table of Comparison

| Feature | Slip Roll | Plate Roll |

|---|---|---|

| Purpose | Bending sheet metal into curves and cylinders | Rolling and shaping heavy metal plates |

| Material Thickness | Up to 1/8 inch (3 mm) typically | Up to several inches thick (depends on machine) |

| Roll Configuration | Three rolls; top roll adjusts vertically | Three rolls; all rolls adjustable for plate contouring |

| Applications | Sheet metal shops, light fabrication, ductwork | Heavy fabrication, shipbuilding, structural components |

| Operation | Manual or motorized; simple setup | Motorized with precise roll controls |

| Cost | Lower cost; affordable for small workshops | Higher cost; industrial level investment |

| Portability | Compact and portable | Large, stationary equipment |

Introduction to Slip Roll and Plate Roll

Slip rolls and plate rolls are essential metalworking machines designed to bend and shape sheet metal into curves or cylinders. Slip rolls feature three rollers--two on the sides and one adjustable in the middle--allowing you to feed metal through for gradual bending, ideal for lighter gauge materials and smaller radius curves. Plate rolls, by contrast, are built with heavier-duty rollers and stronger frames to handle thicker metal plates, producing larger radius bends suitable for structural components and industrial applications.

Overview of Metal Rolling Machines

Slip rolls and plate rolls are essential metal rolling machines used for shaping sheet metal into curved forms or cylinders. Slip rolls typically handle thinner sheets and smaller radii, offering precise control through individually adjustable rollers, making them ideal for detailed work or custom shapes. Plate rolls accommodate thicker metal plates and larger diameters with three or four rollers that provide strong bending capacity, suited for industrial-scale fabrication and heavy-duty applications.

What is a Slip Roll Machine?

A Slip Roll Machine is a metal forming tool specifically designed to bend and roll sheet metal into cylindrical shapes by feeding the material between three rolls, where the slip feature allows the top roll to disengage and reset without rotating the workpiece. Unlike a Plate Roll, which uses powered three or four-roll setups for thicker or heavier steel plates, Slip Rolls are ideal for lighter gauges and precision curves, making them highly suitable for fabricators working on thinner metals. Your choice between these machines depends on the material thickness and the required bending accuracy.

What is a Plate Roll Machine?

A plate roll machine is a metalworking tool designed to bend and shape flat metal sheets into cylindrical or conical forms by passing the material through a series of adjustable rollers. Unlike slip rolls, which primarily handle lighter materials with manual adjustments, plate rolls are engineered to process thicker, heavier plates with precise control and automated features. Your choice between a slip roll and plate roll machine depends on the thickness and size of the metal, with plate rolls offering greater power and accuracy for industrial-scale metal forming.

Key Differences Between Slip Roll and Plate Roll

Slip rolls are designed for bending thin sheets and provide a manual operation with adjustable rollers to create curves, while plate rolls handle thicker metal plates using powered rollers for uniform bending. The key differences between slip rolls and plate rolls lie in their capacity, with slip rolls suited for light gauge materials and plate rolls capable of managing heavy gauge or large-diameter plates. Your choice depends on the material thickness and precision requirements, as slip rolls offer flexibility for small jobs and plate rolls deliver consistent, large-scale bending.

Material Handling and Thickness Capabilities

Slip rolls are ideal for handling lighter gauge materials, typically up to 16 gauge steel, offering precision in rolling thin sheets with ease. Plate rolls are designed for heavier material handling, capable of rolling thicker metal plates ranging from 1/4 inch to several inches in thickness, making them suitable for industrial and heavy-duty applications. Your choice depends on the thickness and weight of the material, with slip rolls excelling in agility and plate rolls providing robust capability for thicker, heavier metals.

Applications: When to Use Slip Roll vs. Plate Roll

Slip rolls are ideal for bending thin sheets of metal into simple curves or cylinders, commonly used in light fabrication, HVAC ductwork, and artistic metalwork. Plate rolls are designed for heavier-duty applications, capable of rolling thicker, wider plates used in structural components, shipbuilding, and heavy machinery parts. Choose slip rolls for precision and lighter gauges, while plate rolls suit projects requiring high-strength materials and larger diameters.

Precision and Output Quality

Slip rolls provide moderate precision ideal for smaller or less complex sheet metal curves, while plate rolls deliver higher accuracy and smoother bends suitable for thicker metal sheets. Plate rolls use synchronized rollers to ensure uniform pressure distribution, resulting in superior output quality and consistent radii. Precision in plate rolling reduces material stress and enhances the final product's structural integrity compared to slip rolling.

Cost Considerations and Efficiency

Slip rolls typically offer a lower initial cost and are suitable for small to medium sheet metal bending tasks, making them more budget-friendly for workshops with limited space or resources. Plate rolls, designed for heavier gauge and larger diameter metal rolling, involve higher upfront investment but provide greater efficiency for industrial-scale metal forming due to their robust construction and automated features. Evaluating specific project requirements and production volume helps determine whether the cost efficiency of a simpler slip roll or the enhanced throughput of a plate roll is the optimal choice.

Choosing the Right Rolling Machine for Your Project

Slip rolls and plate rolls serve different purposes in metal forming, with slip rolls best suited for creating cylindrical shapes from sheet metal, while plate rolls are designed to handle thicker, heavier materials and produce larger diameter rolls. When choosing the right rolling machine for your project, consider the material thickness, roll diameter requirements, and precision needed, as these factors determine the machine's capacity and effectiveness. Evaluating your specific project demands helps ensure you select a slip roll for finer work or a plate roll for heavy-duty applications, optimizing your workflow and output quality.

Slip roll vs plate roll Infographic

libmatt.com

libmatt.com