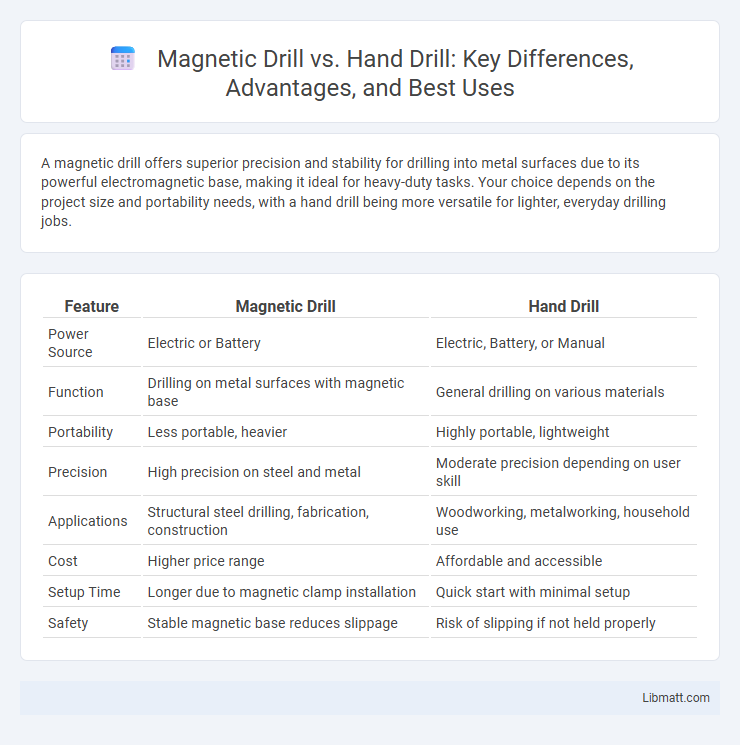

A magnetic drill offers superior precision and stability for drilling into metal surfaces due to its powerful electromagnetic base, making it ideal for heavy-duty tasks. Your choice depends on the project size and portability needs, with a hand drill being more versatile for lighter, everyday drilling jobs.

Table of Comparison

| Feature | Magnetic Drill | Hand Drill |

|---|---|---|

| Power Source | Electric or Battery | Electric, Battery, or Manual |

| Function | Drilling on metal surfaces with magnetic base | General drilling on various materials |

| Portability | Less portable, heavier | Highly portable, lightweight |

| Precision | High precision on steel and metal | Moderate precision depending on user skill |

| Applications | Structural steel drilling, fabrication, construction | Woodworking, metalworking, household use |

| Cost | Higher price range | Affordable and accessible |

| Setup Time | Longer due to magnetic clamp installation | Quick start with minimal setup |

| Safety | Stable magnetic base reduces slippage | Risk of slipping if not held properly |

Introduction to Magnetic Drill vs Hand Drill

Magnetic drills offer powerful, precise drilling specifically designed for metal surfaces, utilizing a magnetic base to secure the drill firmly in place during operation. Hand drills provide greater versatility and portability, making them ideal for a variety of materials and locations where magnetic adherence is not feasible. Your choice between these tools depends on the specific requirements of your project, such as material type, drilling precision, and site mobility.

Key Differences Between Magnetic and Hand Drills

Magnetic drills utilize electromagnetic bases to securely attach to metal surfaces, offering enhanced precision and stability during drilling, especially on steel structures. Hand drills provide greater portability and versatility for a variety of materials but may lack the consistent accuracy and power of magnetic drills. Your choice depends on specific project needs, such as working on metal beams or requiring handheld maneuverability.

When to Use a Magnetic Drill

A magnetic drill is ideal for drilling precise holes in steel or other ferromagnetic metals, especially when working on vertical or overhead surfaces where stability is crucial. Your best choice is a magnetic drill when portability is less important than accuracy and when drilling large-diameter holes in structural steel or metal fabrication projects. Unlike hand drills, magnetic drills offer increased torque, safety, and clean, controlled cuts on magnetic surfaces.

When to Use a Hand Drill

Use a hand drill when working on lighter materials or in tight, hard-to-reach spaces where portability and flexibility are essential. It is ideal for general-purpose drilling, especially on wood, metal, or plastic, where precise control and maneuverability are required without the need for heavy-duty drilling power. Your choice should depend on the project size, material thickness, and whether you need the magnetic drill's strong magnetic base for stable drilling on steel surfaces.

Performance and Efficiency Comparison

Magnetic drills deliver superior performance and efficiency compared to hand drills due to their powerful electromagnetic base that secures the tool firmly to metal surfaces, enabling precise, stable, and faster drilling. Their high-torque motors and ability to handle larger diameter holes with less operator fatigue enhance productivity in industrial and construction settings. While hand drills offer portability and versatility, magnetic drills excel in demanding tasks requiring consistent accuracy and heavy-duty capacity.

Precision and Accuracy of Each Drill Type

Magnetic drills offer superior precision and accuracy due to their stable base, which firmly attaches to metal surfaces, minimizing movement during drilling. Hand drills, while more versatile for different materials and positions, often sacrifice accuracy because they rely heavily on user control and steadiness. The magnetic drill's reliance on a fixed magnetic base results in consistently straighter holes, crucial in metal fabrication and construction projects requiring precise alignment.

Portability and Ease of Use

Magnetic drills offer superior stability and precision when working on metal surfaces but tend to be heavier and less portable than hand drills, which are lightweight and easy to carry for various tasks. Hand drills provide greater maneuverability in tight spaces and are simpler to operate without the need for magnetic adhesion, making them ideal for quick, off-site jobs. Your choice depends on whether you prioritize portability and ease of use or the enhanced accuracy and stability for metal drilling projects.

Safety Considerations for Both Tools

Magnetic drills offer enhanced safety features such as strong electromagnetic bases that securely anchor the tool to metal surfaces, reducing the risk of slippage and operator injury compared to traditional hand drills. Hand drills require careful handling and the use of personal protective equipment like gloves and safety goggles to prevent accidents from bit slips and debris. Both tools necessitate strict adherence to manufacturer guidelines and regular maintenance checks to ensure safe operation and minimize hazards in metalworking environments.

Cost Analysis: Magnetic Drill vs Hand Drill

Magnetic drills typically cost between $500 and $2,000, reflecting their advanced features and precision for metal drilling applications, while hand drills range from $20 to $150, offering a budget-friendly option for general use. Although magnetic drills require a higher initial investment, their efficiency and durability reduce labor time and maintenance expenses over the long term. Hand drills incur lower upfront costs but may lead to higher operational costs due to slower work speed and less specialized performance in metal drilling tasks.

Choosing the Right Drill for Your Project

Magnetic drills provide powerful, precise drilling on metal surfaces with a strong electromagnetic base, ideal for heavy-duty industrial tasks requiring stability and accuracy. Hand drills offer greater versatility and portability for lighter, general-purpose drilling on various materials, giving You flexibility in different environments. Selecting the right drill depends on your project's material, precision needs, and mobility requirements to ensure efficiency and optimal results.

Magnetic drill vs hand drill Infographic

libmatt.com

libmatt.com