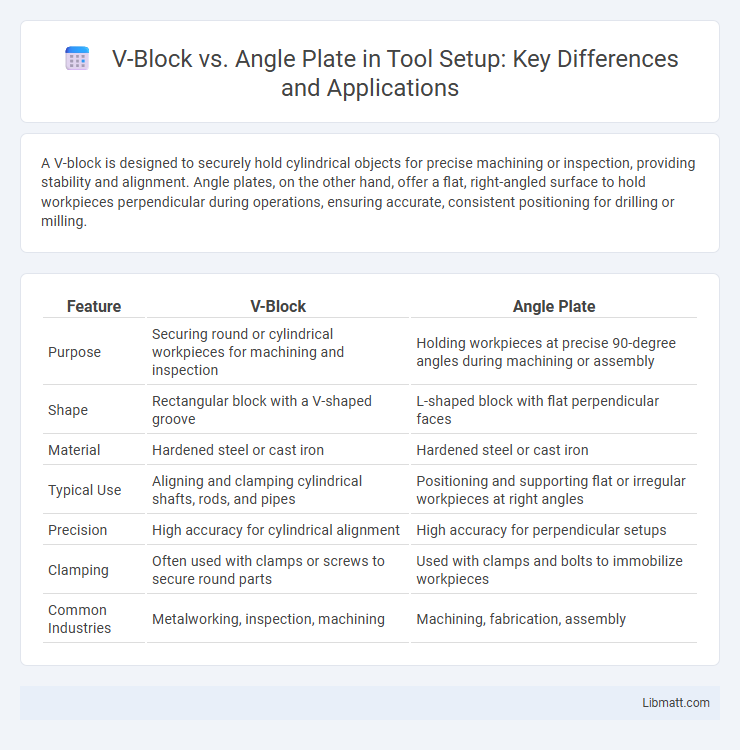

A V-block is designed to securely hold cylindrical objects for precise machining or inspection, providing stability and alignment. Angle plates, on the other hand, offer a flat, right-angled surface to hold workpieces perpendicular during operations, ensuring accurate, consistent positioning for drilling or milling.

Table of Comparison

| Feature | V-Block | Angle Plate |

|---|---|---|

| Purpose | Securing round or cylindrical workpieces for machining and inspection | Holding workpieces at precise 90-degree angles during machining or assembly |

| Shape | Rectangular block with a V-shaped groove | L-shaped block with flat perpendicular faces |

| Material | Hardened steel or cast iron | Hardened steel or cast iron |

| Typical Use | Aligning and clamping cylindrical shafts, rods, and pipes | Positioning and supporting flat or irregular workpieces at right angles |

| Precision | High accuracy for cylindrical alignment | High accuracy for perpendicular setups |

| Clamping | Often used with clamps or screws to secure round parts | Used with clamps and bolts to immobilize workpieces |

| Common Industries | Metalworking, inspection, machining | Machining, fabrication, assembly |

Introduction to V-Block and Angle Plate

V-Blocks and angle plates are essential tools in precision machining and metalworking for securing workpieces during inspection or machining. V-Blocks feature a V-shaped groove designed to hold cylindrical objects firmly, whereas angle plates provide a stable, right-angle surface for clamping flat or irregularly shaped components. Your choice between these tools depends on the specific geometry and orientation required for accurate measurement or machining tasks.

Definition and Purpose of V-Block

V-blocks are precision metalworking tools designed to hold cylindrical objects securely during machining or inspection by providing a stable, V-shaped groove. Their primary purpose is to ensure accurate alignment and support for round workpieces, facilitating precise measurements or operations. You can rely on V-blocks to maintain consistent positioning, which contrasts with angle plates that are mainly used to hold flat or irregular-shaped parts at specific angles.

Definition and Purpose of Angle Plate

An angle plate is a precision metal tool used in machining to hold workpieces perpendicular to the base during inspection or milling. Unlike V-blocks, which are designed to securely hold cylindrical objects, angle plates provide stable support for flat or square components requiring accurate 90-degree alignment. These plates are essential for ensuring precision in drilling, grinding, and layout tasks by maintaining exact right-angle positioning.

Key Differences Between V-Block and Angle Plate

V-blocks are precision tools designed to hold cylindrical workpieces securely during machining or inspection, featuring a V-shaped groove that aligns round objects accurately. Angle plates, constructed with two perpendicular flat surfaces, provide stable support and precise 90-degree positioning for workpieces, mainly used for layout, inspection, or clamping irregular shapes. The key differences lie in their shape, function, and application: V-blocks are specialized for round materials alignment, whereas angle plates are versatile for supporting and holding parts at right angles.

Construction and Design Features

V-blocks feature a hardened steel body with a precise 90-degree V-groove designed to securely hold cylindrical workpieces during inspection or machining. Angle plates consist of right-angled steel plates with accurately machined faces and slots for clamping flat or irregular-shaped objects at a fixed 90-degree angle. Your choice depends on whether you need to stabilize round rods or set up workpieces at precise angles in metalworking and inspection tasks.

Common Applications in Metalworking

V-blocks and angle plates serve distinct purposes in metalworking: V-blocks provide stable support for cylindrical workpieces during precision drilling or grinding, ensuring alignment and reducing movement. Angle plates are primarily used to hold workpieces at precise right angles for layout, machining, or inspection tasks, facilitating accurate and repeatable setups. Your choice between these tools depends on the geometry of the metal piece and the specific machining operation required.

Advantages of Using V-Block

V-blocks provide precise positioning and stable support for cylindrical workpieces during machining, ensuring accurate measurements and consistent results. Their design allows for easy clamping and rotation of round objects, enhancing efficiency and reducing setup time. You benefit from improved alignment and versatility when working on shafts, pipes, or rods compared to angle plates.

Benefits of Angle Plate in Machining

Angle plates provide precise 90-degree positioning, ensuring accurate and stable workpiece clamping during machining operations. Their versatility allows holders and clamps to be mounted on multiple surfaces, enhancing setup flexibility and reducing machining time. You gain improved consistency and efficiency by using angle plates for complex geometries and intricate machining tasks.

Factors to Consider When Choosing

When selecting between a V-block and an angle plate, consider the shape and size of the workpiece, as V-blocks are ideal for cylindrical objects while angle plates excel with flat, rectangular materials. Precision requirements and clamping stability are critical, with V-blocks offering secure positioning for round stock and angle plates providing versatile support for various machining operations. Material composition and durability also matter, with hardened steel V-blocks and cast iron angle plates ensuring longevity under repetitive use.

Conclusion: V-Block or Angle Plate?

Choosing between a V-block and an angle plate depends on the machining task; V-blocks excel in securely holding cylindrical workpieces during precision inspection or marking, while angle plates provide stable right-angle support for rectangular or irregularly shaped components in milling or drilling. V-blocks offer superior alignment for round objects due to their V-shaped grooves, whereas angle plates deliver versatility in positioning parts at precise angles. Selecting the tool should be based on workpiece geometry and required stability for accurate machining outcomes.

V-block vs angle plate Infographic

libmatt.com

libmatt.com