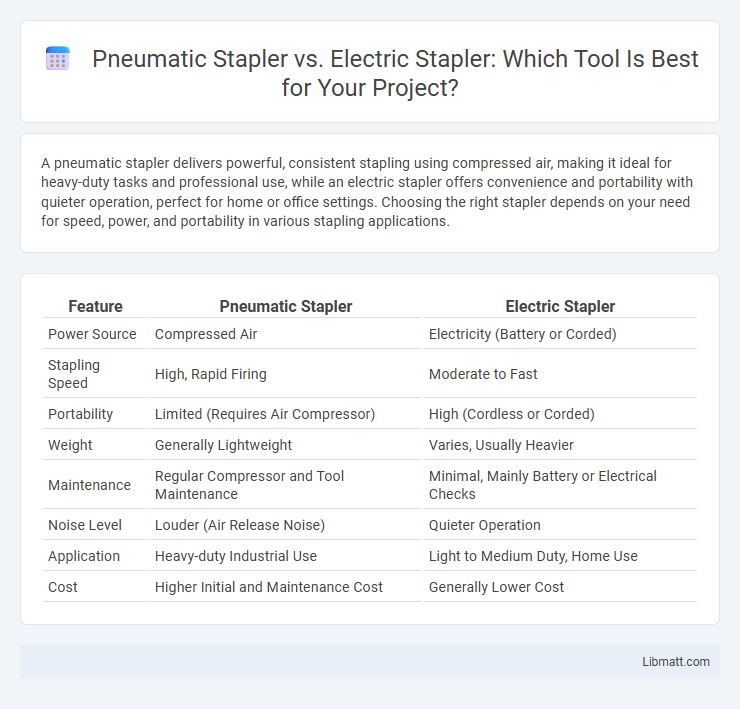

A pneumatic stapler delivers powerful, consistent stapling using compressed air, making it ideal for heavy-duty tasks and professional use, while an electric stapler offers convenience and portability with quieter operation, perfect for home or office settings. Choosing the right stapler depends on your need for speed, power, and portability in various stapling applications.

Table of Comparison

| Feature | Pneumatic Stapler | Electric Stapler |

|---|---|---|

| Power Source | Compressed Air | Electricity (Battery or Corded) |

| Stapling Speed | High, Rapid Firing | Moderate to Fast |

| Portability | Limited (Requires Air Compressor) | High (Cordless or Corded) |

| Weight | Generally Lightweight | Varies, Usually Heavier |

| Maintenance | Regular Compressor and Tool Maintenance | Minimal, Mainly Battery or Electrical Checks |

| Noise Level | Louder (Air Release Noise) | Quieter Operation |

| Application | Heavy-duty Industrial Use | Light to Medium Duty, Home Use |

| Cost | Higher Initial and Maintenance Cost | Generally Lower Cost |

Introduction: Understanding Pneumatic vs Electric Staplers

Pneumatic staplers operate using compressed air, delivering high power and rapid stapling ideal for heavy-duty tasks and industrial applications. Electric staplers utilize battery or corded power, offering greater portability and convenience for light to medium stapling needs. Choosing between pneumatic and electric staplers depends on project scale, frequency, and mobility requirements.

How Pneumatic Staplers Work

Pneumatic staplers operate using compressed air to drive staples into materials with high force and precision. This mechanism ensures rapid stapling cycles, making them ideal for heavy-duty tasks and industrial applications. Your choice of a pneumatic stapler delivers consistent power and durability for demanding projects.

How Electric Staplers Operate

Electric staplers operate using an internal motor powered by electricity, which drives a mechanism to push staples through materials efficiently. The motor activates a ratchet or linear drive system that provides consistent force, allowing for precise and rapid stapling without manual effort. Unlike pneumatic staplers that rely on compressed air, electric staplers require access to a power source or rechargeable battery for operation.

Power and Performance Comparison

A pneumatic stapler delivers higher power and faster performance by utilizing compressed air, making it ideal for heavy-duty tasks and industrial applications. Electric staplers, powered by batteries or cords, offer convenience and portability but may lack the consistent force needed for dense materials. Your choice should depend on the intensity of the work and the type of materials being stapled, with pneumatic models excelling in power and durability.

Ease of Use and User Experience

Pneumatic staplers offer lightweight design and rapid firing speeds, making them ideal for high-volume tasks but require an air compressor for operation. Electric staplers provide cordless convenience and consistent power output, enhancing portability and ease of use for smaller projects or home repairs. Your choice depends on whether you prioritize mobility and simplicity or high productivity and professional use.

Portability and Accessibility

Pneumatic staplers require an air compressor, limiting their portability due to the need for a heavy power source and hoses. Electric staplers, powered by rechargeable batteries or standard outlets, offer greater accessibility and convenience for on-the-go projects. Your choice depends on whether you prioritize mobile ease or consistent power supply in your work environment.

Maintenance and Durability

Pneumatic staplers generally require regular maintenance including lubrication and air filter cleaning to ensure optimal performance and prevent wear, making them highly durable under heavy use. Electric staplers demand less frequent maintenance but may experience shorter lifespans due to electronic component wear and battery degradation. Your choice depends on balancing the ease of upkeep with long-term durability for specific stapling tasks.

Safety Considerations

Pneumatic staplers require compressed air, which demands proper handling to prevent accidents such as air hose detachment or sudden tool movement, posing potential safety risks. Electric staplers offer greater control with built-in safety features like trigger locks and reduced recoil, lowering the likelihood of accidental firing or user injury. Users must follow manufacturer guidelines and wear protective gear regardless of the stapler type to ensure safe operation in various work environments.

Cost Analysis: Initial Investment and Long-Term Value

Pneumatic staplers typically require a higher initial investment due to the cost of the compressor and maintenance, whereas electric staplers have a lower upfront price and minimal upkeep. Long-term value for pneumatic staplers is driven by their durability and efficiency in high-volume applications, reducing downtime and operational costs. Electric staplers provide cost savings in smaller tasks and portable settings but may incur more frequent replacements over extended heavy use.

Choosing the Right Stapler for Your Needs

Choosing between a pneumatic stapler and an electric stapler depends on your project scale and precision requirements. Pneumatic staplers deliver powerful, consistent force ideal for heavy-duty tasks and high-volume work, while electric staplers offer convenience with quieter operation and portability for lighter or indoor jobs. Evaluating your work environment and frequency ensures you select the stapler that optimizes efficiency and comfort for your needs.

Pneumatic stapler vs electric stapler Infographic

libmatt.com

libmatt.com