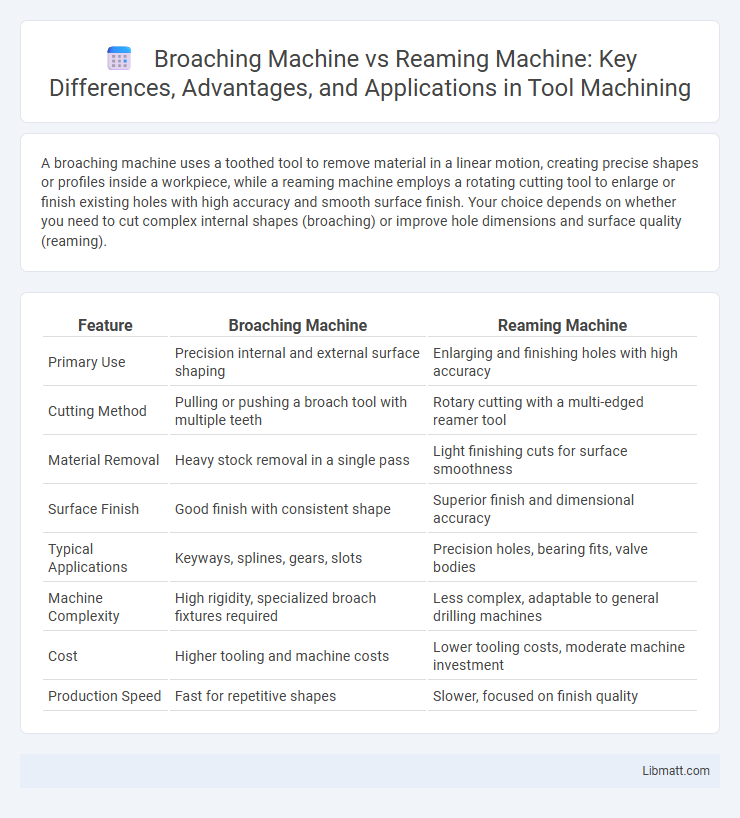

A broaching machine uses a toothed tool to remove material in a linear motion, creating precise shapes or profiles inside a workpiece, while a reaming machine employs a rotating cutting tool to enlarge or finish existing holes with high accuracy and smooth surface finish. Your choice depends on whether you need to cut complex internal shapes (broaching) or improve hole dimensions and surface quality (reaming).

Table of Comparison

| Feature | Broaching Machine | Reaming Machine |

|---|---|---|

| Primary Use | Precision internal and external surface shaping | Enlarging and finishing holes with high accuracy |

| Cutting Method | Pulling or pushing a broach tool with multiple teeth | Rotary cutting with a multi-edged reamer tool |

| Material Removal | Heavy stock removal in a single pass | Light finishing cuts for surface smoothness |

| Surface Finish | Good finish with consistent shape | Superior finish and dimensional accuracy |

| Typical Applications | Keyways, splines, gears, slots | Precision holes, bearing fits, valve bodies |

| Machine Complexity | High rigidity, specialized broach fixtures required | Less complex, adaptable to general drilling machines |

| Cost | Higher tooling and machine costs | Lower tooling costs, moderate machine investment |

| Production Speed | Fast for repetitive shapes | Slower, focused on finish quality |

Introduction to Broaching and Reaming Machines

Broaching machines use a toothed tool to remove material with a single pass, ideal for creating precise internal shapes and complex profiles in metalworking. Reaming machines employ a multi-edge cutting tool designed to finish drilled holes with high accuracy and smooth surface finish. Your choice depends on whether you need high-volume shape cutting or fine-tuning and sizing of pre-drilled holes.

Core Functions of Broaching Machines

Broaching machines specialize in precision machining processes that remove material through a linear motion using a toothed tool called a broach, ideal for creating keyways, splines, and complex internal or external profiles with high accuracy. These machines excel in producing consistent, sharp-edged geometries in hard materials, crucial for automotive, aerospace, and manufacturing industries requiring tight tolerances. Unlike reaming machines, which primarily focus on enlarging and finishing pre-drilled holes to exact diameters and smooth finishes, broaching machines perform material removal in a single pass, enhancing efficiency in shaping intricate and irregular surfaces.

Key Features of Reaming Machines

Reaming machines feature precise axial alignment capabilities and variable speed control to ensure a smooth finish and exact hole dimensions. Their advanced cutting tools, often made from high-speed steel or carbide, enable consistent material removal with minimal surface roughness and tight tolerance adherence. These machines are optimized for fine sizing and surface finishing after drilling or broaching, delivering enhanced dimensional accuracy in metalworking applications.

Broaching Process Overview

Broaching machines use a toothed tool called a broach to remove material in a single pass, creating precise shapes and internal features such as keyways and splines. The broaching process involves linear motion where the broach cuts with multiple teeth, each progressively removing material for high accuracy and surface finish. In contrast, reaming machines enlarge holes to exact dimensions with a rotating multi-edged tool, focusing mainly on finishing rather than shaping complex profiles.

Reaming Process Overview

Reaming is a precision machining process used to enlarge and finish existing holes to exact dimensions with smooth surface finishes, often following drilling or boring operations. Reaming machines use rotary tools called reamers to achieve tight tolerances and maintain hole alignment by removing minimal material. Unlike broaching machines that cut profiles or shapes in a single pass, reaming machines focus exclusively on improving hole quality and size accuracy.

Types of Workpieces Suitable for Broaching

Broaching machines are ideal for workpieces requiring precision keyways, splines, and internal or external profiles on metals such as steel, aluminum, and cast iron. These machines excel in processing complex shapes with fine surface finishes and tight tolerances, commonly used in automotive, aerospace, and heavy machinery industries. In contrast, reaming machines are primarily suited for enlarging and finishing pre-drilled holes to exact sizes with improved surface texture, typically in softer metals or alloys where hole accuracy and smoothness are critical.

Typical Applications of Reaming Machines

Reaming machines are typically used in precision machining to enlarge and finish holes to exact dimensions, ensuring smooth surfaces and tight tolerances. Common applications include automotive engine components, aerospace parts, and hydraulic systems where accurate hole sizing and surface finish are critical. These machines excel in achieving fine hole finishes and maintaining concentricity in metalworking industries.

Precision and Surface Finish Comparison

Broaching machines deliver exceptional precision by removing material with a single, continuous cutting action, resulting in highly accurate dimensions and consistent surface finishes ideal for complex internal shapes. Reaming machines enhance pre-drilled holes by slightly enlarging and smoothing them, providing superior surface finishes but with less dimensional control compared to broaching. Your choice depends on whether ultra-precise geometry or improved surface quality is the primary requirement for the workpiece.

Cost Considerations: Broaching vs Reaming

Broaching machines typically involve higher initial investment costs due to complex tooling and specialized equipment, making them more suitable for high-volume production runs. Reaming machines generally incur lower setup and tooling expenses, offering cost-effective precision hole finishing for smaller batch sizes. The choice between broaching and reaming hinges on production volume, desired tolerances, and overall budget constraints.

Choosing the Right Machine for Your Application

Choosing the right machine between broaching and reaming depends on your specific application requirements such as hole size, finish quality, and production volume. Broaching machines excel at producing precise shapes and complex profiles in high-volume operations, while reaming machines are ideal for achieving tight tolerances and smooth finishes on existing holes. Evaluating the material, desired hole specifications, and budget will help determine whether a broaching or reaming machine best suits your manufacturing needs.

Broaching machine vs reaming machine Infographic

libmatt.com

libmatt.com