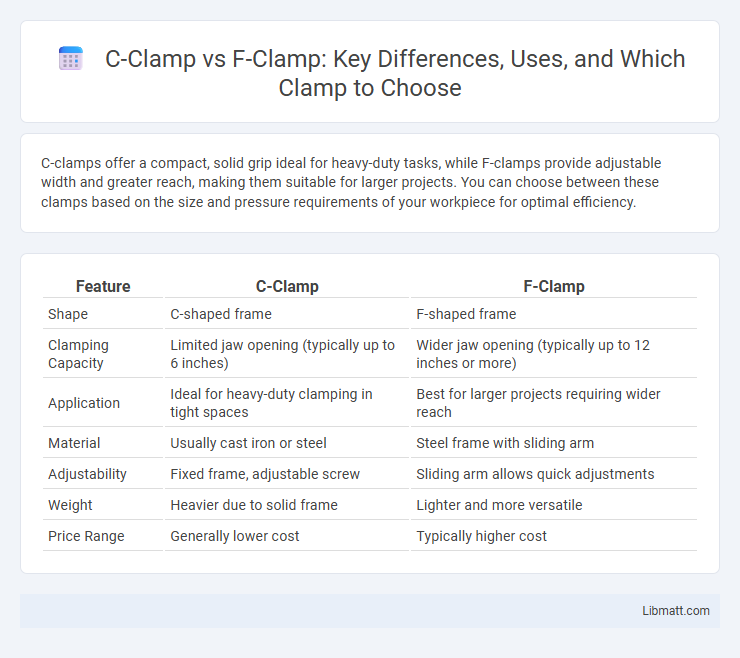

C-clamps offer a compact, solid grip ideal for heavy-duty tasks, while F-clamps provide adjustable width and greater reach, making them suitable for larger projects. You can choose between these clamps based on the size and pressure requirements of your workpiece for optimal efficiency.

Table of Comparison

| Feature | C-Clamp | F-Clamp |

|---|---|---|

| Shape | C-shaped frame | F-shaped frame |

| Clamping Capacity | Limited jaw opening (typically up to 6 inches) | Wider jaw opening (typically up to 12 inches or more) |

| Application | Ideal for heavy-duty clamping in tight spaces | Best for larger projects requiring wider reach |

| Material | Usually cast iron or steel | Steel frame with sliding arm |

| Adjustability | Fixed frame, adjustable screw | Sliding arm allows quick adjustments |

| Weight | Heavier due to solid frame | Lighter and more versatile |

| Price Range | Generally lower cost | Typically higher cost |

Introduction to C-Clamp and F-Clamp

C-clamps and F-clamps are essential tools used for securing materials tightly during woodworking, metalworking, and assembly tasks. A C-clamp features a C-shaped frame and a threaded screw that applies pressure, making it ideal for heavy-duty clamping on smaller projects. In contrast, F-clamps have a wider reach with an adjustable sliding arm and a fixed arm, allowing for clamping larger or irregularly shaped objects efficiently.

Key Features of C-Clamps

C-clamps feature a robust, C-shaped frame with a threaded screw for adjustable clamping pressure, making them ideal for holding workpieces securely during woodworking or metalworking tasks. Their compact design allows for easy access in tight spaces and provides strong, focused clamping force suitable for smaller projects. You can rely on C-clamps for precise, stable grip applications where controlled pressure is essential.

Key Features of F-Clamps

F-clamps feature a longer sliding arm that provides greater reach and versatility compared to C-clamps, making them ideal for clamping wide or irregularly shaped objects. They typically have a quick-adjust sliding mechanism for rapid positioning and a screw handle for secure, precise tightening. The flat, wide jaws of F-clamps distribute pressure evenly, reducing the risk of damaging delicate materials during woodworking or metalworking projects.

Primary Uses and Applications

C-clamps excel in woodworking, metalworking, and welding tasks where strong, steady pressure is needed in confined spaces or on smaller workpieces. F-clamps provide greater adjustable throat depth and clamping capacity, making them ideal for larger projects such as cabinetry, furniture assembly, and clamping wide or irregularly shaped materials. Both clamps are essential in workshop settings, with C-clamps favoring precision hold and F-clamps offering versatile reach and pressure distribution.

Material and Build Quality Comparison

C-clamps are typically made from cast iron or forged steel, offering high durability and strong clamping force ideal for heavy-duty applications. F-clamps often feature a combination of steel bars and cast iron or steel jaws, providing adjustable opening sizes and a robust, yet slightly lighter build for versatility in woodworking. Both clamps exhibit solid construction, but C-clamps prioritize maximum pressure, while F-clamps balance strength with greater reach and adjustability.

Clamping Force and Capacity Differences

C-clamps typically offer higher clamping force due to their robust construction and screw mechanism, making them ideal for heavy-duty tasks requiring secure holds. F-clamps provide greater clamping capacity with adjustable sliding bars, allowing them to accommodate larger or irregularly shaped materials more flexibly. The choice between the two depends on the balance needed between maximum force and the size of the workpiece.

Ease of Use and Adjustability

C-clamps offer a simple screw mechanism that provides strong, stable clamping but can be slower to adjust and position compared to F-clamps. F-clamps feature a sliding arm with a quick-release trigger, allowing faster, more precise adjustments and easier handling for larger or irregularly shaped workpieces. The ergonomic design of F-clamps often enhances user comfort and control during repetitive clamping tasks.

Pros and Cons of C-Clamps

C-clamps offer strong, reliable clamping pressure ideal for metalworking and woodworking, with a robust frame that resists bending under heavy loads. However, their limited throat depth restricts the size of materials you can clamp, making them less versatile for larger projects. Your choice of clamp should consider the balance between C-clamps' durability and their size constraints.

Pros and Cons of F-Clamps

F-clamps offer adjustable reach and strong clamping pressure, making them ideal for woodworking and metalworking tasks requiring versatility and precision. Their sliding arm design allows easy adjustment for various material thicknesses, while the wide opening capacity supports larger workpieces compared to C-clamps. You may find F-clamps heavier and less suited for tight spaces, and their moving parts can sometimes limit maximum pressure versus the rigid frame of C-clamps.

Choosing the Right Clamp for Your Project

Selecting the right clamp for your project depends on the specific application and clamping force needed. C-clamps offer strong, direct pressure ideal for heavy-duty metalwork or woodworking, while F-clamps provide adjustable reach and increased versatility for larger or irregularly shaped materials. Understanding your project's size and pressure requirements ensures that your clamp choice maximizes efficiency and safety.

C-clamp vs F-clamp Infographic

libmatt.com

libmatt.com