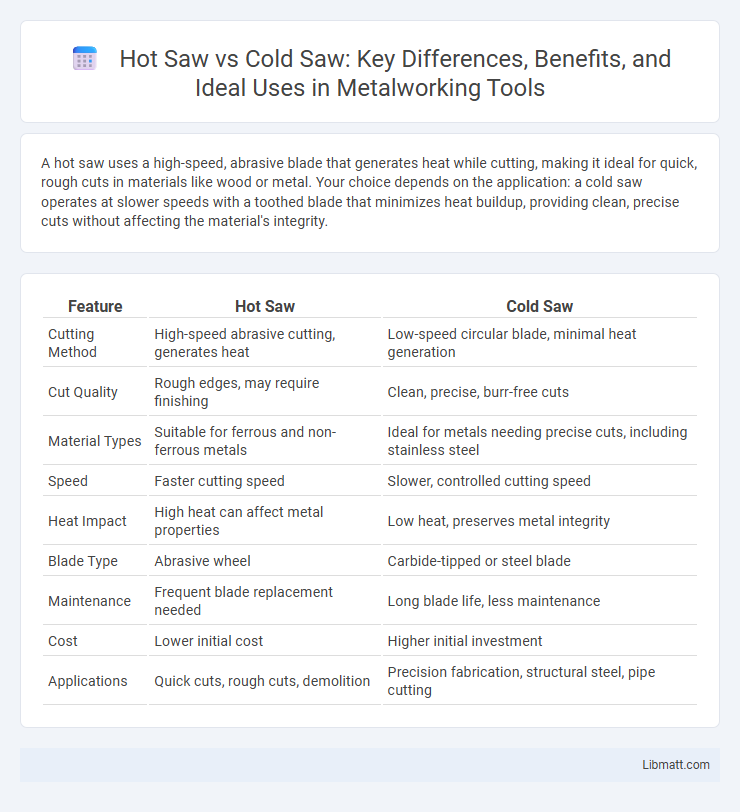

A hot saw uses a high-speed, abrasive blade that generates heat while cutting, making it ideal for quick, rough cuts in materials like wood or metal. Your choice depends on the application: a cold saw operates at slower speeds with a toothed blade that minimizes heat buildup, providing clean, precise cuts without affecting the material's integrity.

Table of Comparison

| Feature | Hot Saw | Cold Saw |

|---|---|---|

| Cutting Method | High-speed abrasive cutting, generates heat | Low-speed circular blade, minimal heat generation |

| Cut Quality | Rough edges, may require finishing | Clean, precise, burr-free cuts |

| Material Types | Suitable for ferrous and non-ferrous metals | Ideal for metals needing precise cuts, including stainless steel |

| Speed | Faster cutting speed | Slower, controlled cutting speed |

| Heat Impact | High heat can affect metal properties | Low heat, preserves metal integrity |

| Blade Type | Abrasive wheel | Carbide-tipped or steel blade |

| Maintenance | Frequent blade replacement needed | Long blade life, less maintenance |

| Cost | Lower initial cost | Higher initial investment |

| Applications | Quick cuts, rough cuts, demolition | Precision fabrication, structural steel, pipe cutting |

Introduction to Hot Saws and Cold Saws

Hot saws operate using a powerful engine to spin a large blade at extremely high speeds, efficiently cutting through thick and dense materials like logs or metal pipes. Cold saws, in contrast, utilize a circular blade powered by an electric motor that cuts material without generating excessive heat, preserving the integrity of metals and reducing the risk of warping. Understanding the differences between hot saw and cold saw technologies helps you choose the right tool for precision cutting or heavy-duty applications.

How Hot Saws Work

Hot saws operate by rapidly spinning a large, carbide-tipped blade powered by a high-horsepower two-stroke engine, generating intense heat that allows for quick and efficient cutting of thick metal materials. The heat produced reduces friction and softens the metal, enabling smoother cuts without excessive blade wear, making hot saws ideal for heavy-duty industrial applications like log cutting and metal fabrication. Precise blade speed control and cooling mechanisms enhance performance and extend the tool's lifespan compared to traditional cold saws.

How Cold Saws Operate

Cold saws operate by using a circular saw blade made of high-speed steel or tungsten carbide designed to cut metal at low speeds, minimizing heat generation and material distortion. The saw blade rotates at a controlled feed rate, allowing for precise cuts with clean edges and reduced burr formation, which preserves the integrity of the workpiece. Your choice of a cold saw ensures efficient metal cutting with less thermal damage compared to hot saws, making it ideal for applications requiring accuracy and surface quality.

Key Differences Between Hot Saws and Cold Saws

Hot saws use high-speed abrasive blades to cut through metal quickly but generate significant heat, often requiring frequent blade replacements due to wear. Cold saws employ low-speed, high-torque circular blades with sharp teeth that cut metal with minimal heat, preserving material integrity and producing clean, precise cuts. Cold saws are ideal for applications needing accuracy and reduced thermal distortion, while hot saws prioritize speed over cut quality.

Advantages of Using Hot Saws

Hot saws offer rapid cutting speeds, making them ideal for processing large volumes of wood efficiently. Their ability to maintain blade temperature reduces the risk of blade warping and improves cutting precision. You benefit from smoother cuts and increased productivity, particularly in heavy-duty woodworking applications.

Benefits of Cold Saw Technology

Cold saw technology offers precise, clean cuts with minimal burring, reducing the need for secondary finishing processes and improving overall efficiency. Your workpiece experiences less heat distortion compared to a hot saw, preserving material integrity and enhancing dimensional accuracy. This technology also extends blade life due to reduced heat generation, making it a cost-effective and reliable choice for metal cutting.

Optimal Applications for Hot Saws

Hot saws excel in cutting thick, dense materials such as hardwood and large logs, making them ideal for heavy-duty woodworking, lumber processing, and timber framing applications. Their high-speed, powerful blades provide rapid, rough cuts with minimal blade wear, maximizing efficiency in tasks requiring fast material removal. These saws are best suited for scenarios demanding quick, aggressive cuts rather than fine, precise finishes.

Best Uses for Cold Saws

Cold saws excel in precision metal cutting due to their low heat generation, making them ideal for materials requiring minimal thermal distortion such as stainless steel, aluminum, and other non-ferrous metals. They are best used in industries like aerospace, automotive, and fabrication shops where clean, accurate cuts with smooth finishes are crucial. Cold saws' slow cutting speed combines with a toothed blade to maintain blade longevity and reduce material waste, providing an efficient solution for repetitive, high-quality cuts.

Factors to Consider When Choosing Hot Saw vs Cold Saw

When choosing between a hot saw and a cold saw, key factors include cutting speed, material type, and precision requirements. Hot saws excel in high-speed cutting of heavy-duty materials like large logs or thick steel, while cold saws provide cleaner, more precise cuts with minimal heat distortion, ideal for sensitive metalwork. Consider blade maintenance, energy consumption, and operational costs to determine the best fit for your specific cutting tasks and production environment.

Conclusion: Which Saw is Right for Your Needs?

Choosing between a hot saw and a cold saw depends on your specific cutting needs and material types. Hot saws excel in high-speed cutting of thick, hard metals but generate more heat and require skilled operation, while cold saws produce precise, clean cuts with minimal heat, ideal for delicate or thin materials. Your decision should consider the balance between cutting speed, material properties, and the desired finish quality to ensure the saw aligns with your project requirements.

Hot saw vs cold saw Infographic

libmatt.com

libmatt.com