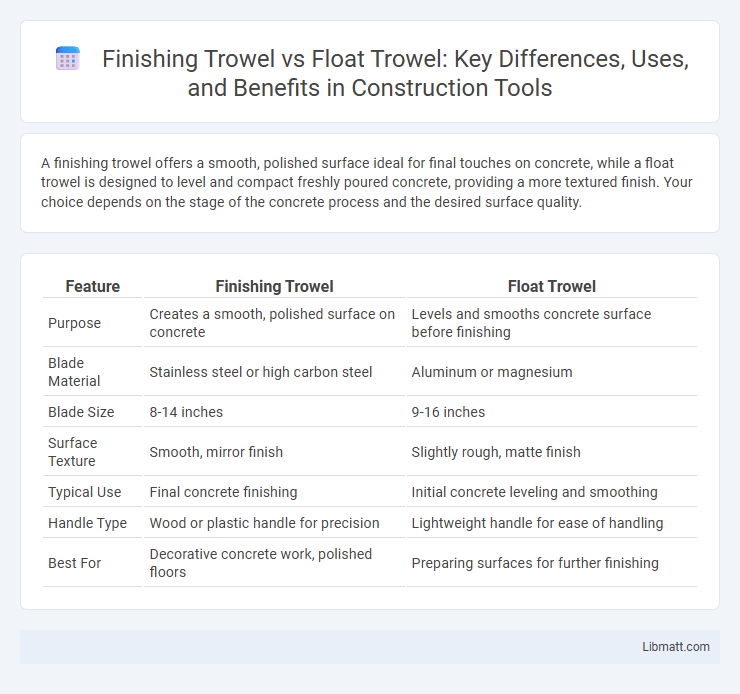

A finishing trowel offers a smooth, polished surface ideal for final touches on concrete, while a float trowel is designed to level and compact freshly poured concrete, providing a more textured finish. Your choice depends on the stage of the concrete process and the desired surface quality.

Table of Comparison

| Feature | Finishing Trowel | Float Trowel |

|---|---|---|

| Purpose | Creates a smooth, polished surface on concrete | Levels and smooths concrete surface before finishing |

| Blade Material | Stainless steel or high carbon steel | Aluminum or magnesium |

| Blade Size | 8-14 inches | 9-16 inches |

| Surface Texture | Smooth, mirror finish | Slightly rough, matte finish |

| Typical Use | Final concrete finishing | Initial concrete leveling and smoothing |

| Handle Type | Wood or plastic handle for precision | Lightweight handle for ease of handling |

| Best For | Decorative concrete work, polished floors | Preparing surfaces for further finishing |

Introduction to Trowels: Purpose and Importance

Finishing trowels and float trowels are essential tools in masonry and concrete work, each serving a distinct purpose in surface finishing. Finishing trowels are designed to create a smooth, polished surface by applying a thin layer of mortar or concrete, while float trowels are used to level and roughen the surface for improved bonding and texture. Understanding the differences in blade design and material helps ensure optimal results in achieving the desired finish and durability.

What Is a Finishing Trowel?

A finishing trowel is a hand tool designed with a flat, smooth steel blade used to create a sleek, polished surface on concrete or plaster. It helps You achieve a refined finish by smoothing and compressing the material, eliminating imperfections and creating a dense, durable layer. Unlike a float trowel, which is typically used for initial leveling and texture, a finishing trowel provides the final, professional-quality surface.

What Is a Float Trowel?

A float trowel is a hand tool used in concrete finishing to smooth and level freshly poured concrete surfaces, typically featuring a flat, rectangular metal blade attached to a handle. Unlike a finishing trowel, which often has a smaller blade for detailed work, a float trowel helps to embed aggregate and remove surface imperfections, creating a firm, uniform base before fine finishing. Using the right float trowel ensures your concrete has an even texture and is properly prepared for final smoothing or sealing.

Key Differences: Finishing Trowel vs Float Trowel

A finishing trowel features a smooth, flat surface ideal for creating polished, even finishes on concrete, while a float trowel typically has a mildly textured surface suited for leveling and smoothing rough concrete before final finishing. Finishing trowels are smaller and designed for precision work, whereas float trowels are larger and used for broader surface coverage during initial stages. The key differences lie in their blade texture, size, and primary purpose in the concrete finishing process.

Material Composition and Durability Comparison

Finishing trowels are typically made from high-quality stainless steel or carbon steel, designed for smooth surface application and enhanced corrosion resistance, ensuring long-term durability. Float trowels often feature magnesium or rubber blades combined with steel handles, offering flexibility and abrasion resistance suited for rougher texturing tasks. The steel construction of finishing trowels provides superior stiffness and edge retention, while float trowels balance durability with a lightweight design for extended use on concrete surfaces.

Best Applications for Finishing Trowels

Finishing trowels are best applied for smoothing and leveling concrete surfaces to achieve a polished, refined texture ideal for floors and walls. They are particularly effective in the final stages of concrete work to create a sleek, uniform appearance by eliminating surface imperfections. Unlike float trowels, which are used for initial surface consolidation and rough texture, finishing trowels provide a superior finish suitable for indoor concrete floors and decorative surfaces.

Best Uses for Float Trowels

Float trowels excel in smoothing and leveling freshly poured concrete surfaces, making them ideal for initial finishing stages. Their flat, wide blades help remove surface imperfections and create a uniform texture, essential for sidewalks, driveways, and slabs. When you need a consistent and durable concrete finish, float trowels provide the best results before moving on to finer finishing tools.

Pros and Cons: Finishing Trowels vs Float Trowels

Finishing trowels offer a smooth, polished surface ideal for detailed finishing work, but they require a skilled hand and frequent cleaning to prevent imperfections. Float trowels excel in leveling rough surfaces and embedding aggregates, providing better grip for subsequent coatings, though they may leave a less refined texture compared to finishing trowels. Choosing the right tool depends on your project needs, balancing ease of use with the desired surface finish quality.

Choosing the Right Trowel for Your Project

Selecting the right trowel depends on the surface finish and material type, with a finishing trowel offering a smoother, polished surface ideal for drywall and concrete, while a float trowel is better suited for leveling and preparing rough surfaces. Finishing trowels typically feature a narrower, flatter blade that allows for precision and fine detail work, contrasting with the wider, more flexible blade of float trowels designed to control texture and remove air bubbles. Understanding project requirements ensures the optimal tool choice, enhancing application quality and durability of surfaces like plaster, stucco, or poured concrete.

Maintenance Tips for Longevity

Maintaining your finishing trowel and float trowel involves cleaning them promptly after use to prevent concrete and mortar buildup, which can cause corrosion or damage. Regularly inspect the blades for nicks or warping, and store the tools in a dry environment to avoid rust. Proper upkeep extends the lifespan of your tools, ensuring consistent performance and smoother finishes in your masonry projects.

Finishing trowel vs float trowel Infographic

libmatt.com

libmatt.com