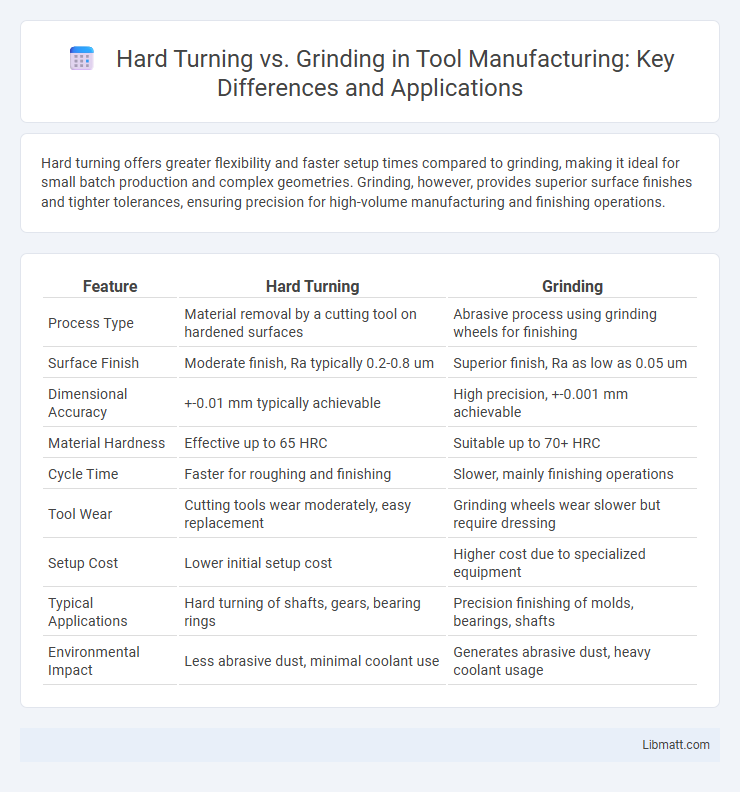

Hard turning offers greater flexibility and faster setup times compared to grinding, making it ideal for small batch production and complex geometries. Grinding, however, provides superior surface finishes and tighter tolerances, ensuring precision for high-volume manufacturing and finishing operations.

Table of Comparison

| Feature | Hard Turning | Grinding |

|---|---|---|

| Process Type | Material removal by a cutting tool on hardened surfaces | Abrasive process using grinding wheels for finishing |

| Surface Finish | Moderate finish, Ra typically 0.2-0.8 um | Superior finish, Ra as low as 0.05 um |

| Dimensional Accuracy | +-0.01 mm typically achievable | High precision, +-0.001 mm achievable |

| Material Hardness | Effective up to 65 HRC | Suitable up to 70+ HRC |

| Cycle Time | Faster for roughing and finishing | Slower, mainly finishing operations |

| Tool Wear | Cutting tools wear moderately, easy replacement | Grinding wheels wear slower but require dressing |

| Setup Cost | Lower initial setup cost | Higher cost due to specialized equipment |

| Typical Applications | Hard turning of shafts, gears, bearing rings | Precision finishing of molds, bearings, shafts |

| Environmental Impact | Less abrasive dust, minimal coolant use | Generates abrasive dust, heavy coolant usage |

Introduction to Hard Turning and Grinding

Hard turning involves machining hardened steel components using a lathe or CNC machine with a single-point cutting tool, achieving precise dimensional accuracy and surface finish on parts typically above 45 HRC hardness. Grinding uses an abrasive wheel to remove material from the surface of hardened workpieces, offering high precision and excellent surface finish, especially for complex shapes and very hard materials. Both processes are essential in manufacturing hardened components, with hard turning preferred for faster material removal and grinding favored for tighter tolerances and superior surface quality.

Core Differences Between Hard Turning and Grinding

Hard turning uses a single-point cutting tool on CNC machines to remove material from hardened steel, offering faster processing and lower costs for parts with less stringent surface finish requirements. Grinding employs an abrasive wheel to achieve superior surface finish and tighter dimensional tolerances, making it ideal for components requiring precise geometry and smoother surfaces. Your choice depends on balancing production speed, cost-efficiency, and the specific surface quality or accuracy needed for the application.

Material Suitability for Hard Turning and Grinding

Hard turning excels in machining materials with hardness levels up to 62 HRC, such as hardened steels, cast irons, and some stainless steels, providing efficient and flexible processing. Grinding, however, is suitable for a broader range of extremely hard materials, including tool steels and carbide, offering superior surface finish and dimensional accuracy. Your choice depends on the material hardness and required surface quality, with hard turning favored for less abrasive materials and grinding preferred for ultra-hard or delicate components.

Surface Finish and Dimensional Accuracy Comparison

Hard turning offers a surface finish typically ranging from Ra 0.2 to 0.8 microns, providing excellent dimensional accuracy for components with complex geometries. Grinding generally achieves superior surface finishes, often below Ra 0.1 microns, with exceptional dimensional control suitable for ultra-precise applications. Your choice depends on the required tolerance and finish quality, as grinding excels in fine surface texture while hard turning delivers faster machining with slightly higher surface roughness.

Tooling Requirements and Machine Compatibility

Hard turning requires specialized carbide or cubic boron nitride (CBN) cutting tools capable of withstanding high temperatures and maintaining edge sharpness, whereas grinding relies on abrasive wheels suited for precise material removal. Machines for hard turning typically involve CNC lathes equipped with rigid spindles and advanced cooling systems to manage heat, while grinding machines utilize dedicated surface or cylindrical grinders with high-speed spindles and vibration damping features. Tooling longevity and machine compatibility directly impact process efficiency and surface finish quality in both hard turning and grinding operations.

Cycle Time and Production Efficiency

Hard turning significantly reduces cycle time compared to grinding by eliminating the need for multiple passes and minimizing setup adjustments, leading to faster material removal rates. Production efficiency improves as hard turning requires less energy consumption and tooling costs while enabling immediate post-machining operations without the need for extended cooling or dressing. Although grinding delivers higher surface finish quality, hard turning's advantage in cycle time makes it more suitable for high-volume manufacturing environments seeking optimal throughput.

Cost Considerations: Hard Turning vs Grinding

Hard turning generally offers lower operational costs compared to grinding due to reduced tooling expenses and shorter cycle times, making it economically advantageous for small to medium production runs. Grinding involves higher initial investment in machinery and abrasives, alongside increased maintenance costs, which can elevate total manufacturing expenses. The choice between hard turning and grinding should weigh the balance between production volume, precision requirements, and overall cost efficiency.

Environmental and Energy Impact

Hard turning generally consumes less energy than grinding due to faster machining times and reduced tool wear, which translates into lower carbon emissions and decreased environmental impact. Grinding processes require substantial coolant use, resulting in higher chemical waste and increased energy consumption to maintain machine cooling systems. By selecting hard turning for hardened materials, you reduce resource usage and support more sustainable manufacturing practices.

Application Scenarios and Industry Use Cases

Hard turning offers precise machining of hardened steels in automotive and aerospace industries, where flexibility and reduced cycle times are crucial. Grinding remains preferred for finishing applications requiring ultra-fine surface finishes and tight tolerances, such as in tool and die manufacturing or bearing production. Your choice depends on balancing cost efficiency and surface quality demands across these industrial scenarios.

Choosing the Right Process for Your Operation

Hard turning offers faster cycle times and greater flexibility for parts with complex geometries, making it ideal for small to medium batch production. Grinding provides superior surface finish and tighter dimensional tolerances, suitable for high-precision applications and large-scale runs. Evaluating factors such as material hardness, part complexity, production volume, and desired surface quality helps determine the optimal process for your operation.

Hard turning vs grinding Infographic

libmatt.com

libmatt.com