A soft face hammer features replaceable, non-marring heads made of rubber or plastic, ideal for delicate surfaces where preventing damage is crucial. Your choice depends on whether you need gentle impact or controlled force absorption, as a dead blow hammer minimizes rebound and delivers concentrated strikes for precision tasks.

Table of Comparison

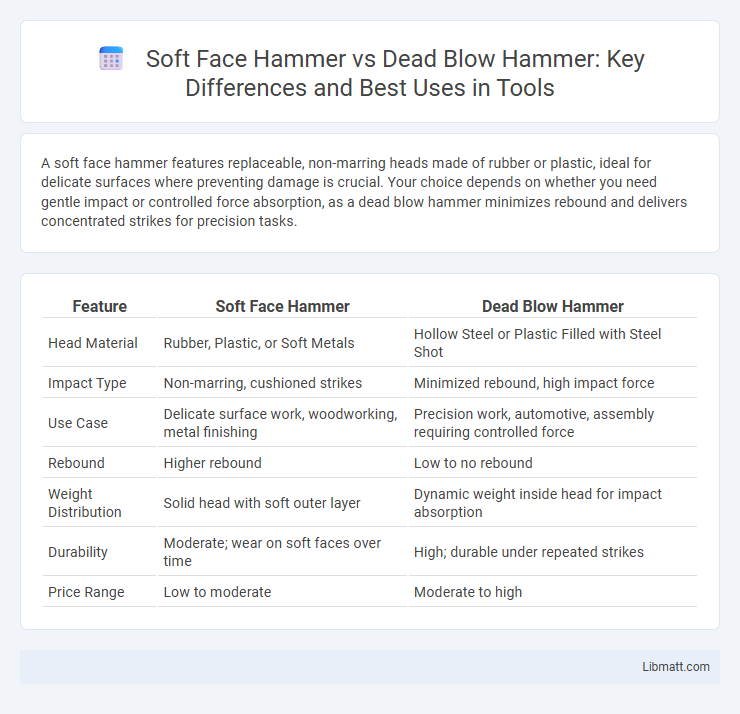

| Feature | Soft Face Hammer | Dead Blow Hammer |

|---|---|---|

| Head Material | Rubber, Plastic, or Soft Metals | Hollow Steel or Plastic Filled with Steel Shot |

| Impact Type | Non-marring, cushioned strikes | Minimized rebound, high impact force |

| Use Case | Delicate surface work, woodworking, metal finishing | Precision work, automotive, assembly requiring controlled force |

| Rebound | Higher rebound | Low to no rebound |

| Weight Distribution | Solid head with soft outer layer | Dynamic weight inside head for impact absorption |

| Durability | Moderate; wear on soft faces over time | High; durable under repeated strikes |

| Price Range | Low to moderate | Moderate to high |

Introduction to Soft Face Hammers and Dead Blow Hammers

Soft face hammers feature non-marring heads made from materials like rubber, plastic, or rawhide, designed to deliver controlled strikes without damaging delicate surfaces. Dead blow hammers incorporate hollow heads filled with sand or steel shot to minimize rebound and maximize impact force, enhancing precision in tasks requiring repetitive striking. Choosing the right tool depends on your need for surface protection with soft face hammers or reduced operator fatigue and increased efficiency with dead blow hammers.

Key Differences Between Soft Face and Dead Blow Hammers

Soft face hammers feature replaceable, non-marring heads made from materials like rubber, plastic, or leather, ideal for delicate surfaces to prevent damage during strikes. Dead blow hammers utilize a hollow head filled with loose steel shot or sand, which reduces rebound and maximizes energy transfer for more controlled, powerful impacts. Your choice depends on the need for surface protection versus impact force and rebound control.

Construction and Material Overview

Soft face hammers typically feature replaceable heads made from materials like rubber, nylon, or rawhide, designed to minimize surface damage while providing controlled impact. Dead blow hammers consist of a hollow steel or plastic body filled with sand or shot, which absorbs and redistributes the force to reduce rebound and deliver a more precise strike. Your choice depends on the need for gentle yet effective force versus reduced rebound for repetitive tasks.

How Soft Face Hammers Work

Soft face hammers work by using replaceable, non-marring faces made of materials like rubber, plastic, or nylon that absorb shock and reduce surface damage during impact. Their design ensures energy is delivered evenly without leaving marks, making them ideal for delicate work on sensitive materials such as metal, wood, or plastics. You benefit from precise, controlled strikes that protect your workpieces while minimizing rebound and operator fatigue.

How Dead Blow Hammers Function

Dead blow hammers function by incorporating a hollow head partially filled with sand or lead shot that absorbs impact shock and minimizes rebound. This design delivers a controlled striking force, reducing damage to the work surface and improving accuracy. Unlike soft face hammers, which use non-metallic faces to prevent marring, dead blow hammers optimize energy transfer through their internal filler mechanism.

Common Applications for Soft Face Hammers

Soft face hammers are ideal for delicate tasks such as assembling furniture, installing trim, and working with soft metals or plastics where surface damage must be avoided. Their non-marring faces, typically made of rubber, plastic, or rawhide, help protect your workpiece while delivering controlled force. These hammers are commonly used in woodworking, metalworking, and automotive industries for precision strikes without leaving dents or scratches.

Typical Uses for Dead Blow Hammers

Dead blow hammers are ideal for automotive assembly, metalworking, and woodworking applications where controlled force without surface damage is required. Their internal sand or shot-filled heads minimize rebound, allowing precise striking on delicate materials and machinery. This makes them essential tools for installing parts, aligning components, and reducing operator fatigue during repetitive strikes.

Pros and Cons: Soft Face Hammer vs Dead Blow Hammer

Soft face hammers offer minimal surface damage and are ideal for delicate materials but can lack impact force compared to dead blow hammers, which provide superior control and reduce rebound through internal weighted chambers. Dead blow hammers excel in precision tasks requiring strong, controlled strikes, yet their heavier weight and complexity might be less suitable for tasks demanding a lighter touch. Your choice should consider the balance between surface protection and impact force depending on the specific application.

Choosing the Right Hammer for Your Project

Selecting the appropriate hammer depends on your project's material and required impact control. Soft face hammers minimize surface damage with non-marring heads, ideal for delicate work on wood or metal. Dead blow hammers reduce rebound and deliver consistent force, making them perfect for precision tasks where controlled impact and reduced vibration matter most.

Maintenance and Safety Tips for Both Types

Soft face hammers require regular inspection of their replaceable heads to avoid wear and ensure safe use, while dead blow hammers need checking for any internal material leakage or dents that could affect performance. Always wear safety goggles and gloves when using either hammer to protect against flying debris and accidental impacts. Store both types in dry environments to prevent corrosion and maintain handle integrity, extending their lifespan and maintaining optimal safety standards.

Soft face hammer vs dead blow hammer Infographic

libmatt.com

libmatt.com