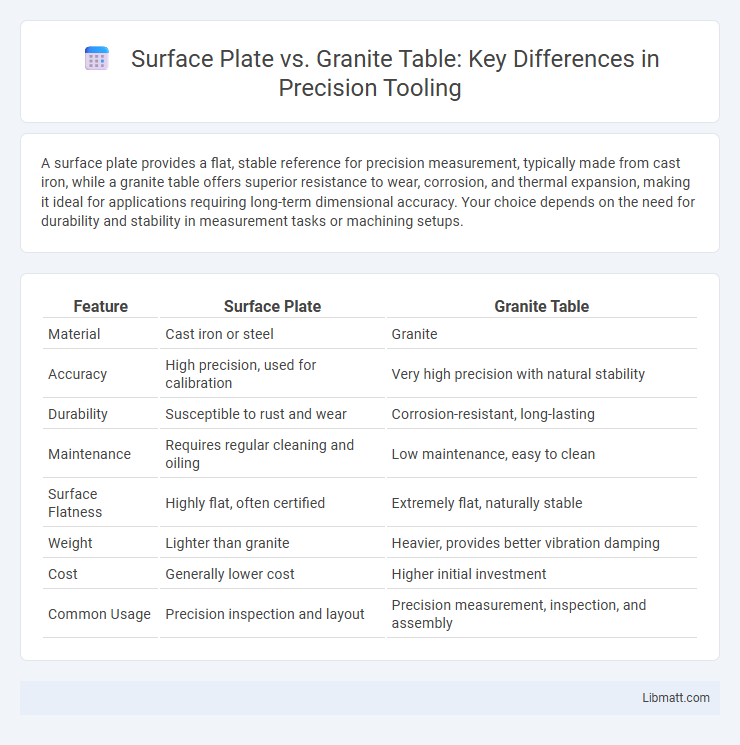

A surface plate provides a flat, stable reference for precision measurement, typically made from cast iron, while a granite table offers superior resistance to wear, corrosion, and thermal expansion, making it ideal for applications requiring long-term dimensional accuracy. Your choice depends on the need for durability and stability in measurement tasks or machining setups.

Table of Comparison

| Feature | Surface Plate | Granite Table |

|---|---|---|

| Material | Cast iron or steel | Granite |

| Accuracy | High precision, used for calibration | Very high precision with natural stability |

| Durability | Susceptible to rust and wear | Corrosion-resistant, long-lasting |

| Maintenance | Requires regular cleaning and oiling | Low maintenance, easy to clean |

| Surface Flatness | Highly flat, often certified | Extremely flat, naturally stable |

| Weight | Lighter than granite | Heavier, provides better vibration damping |

| Cost | Generally lower cost | Higher initial investment |

| Common Usage | Precision inspection and layout | Precision measurement, inspection, and assembly |

Introduction to Surface Plates and Granite Tables

Surface plates and granite tables serve as essential tools in precision measurement and inspection processes across various industries. Surface plates provide a flat reference surface, typically made from cast iron, for aligning and inspecting parts with high accuracy. Granite tables, known for their exceptional stability and resistance to wear, offer superior flatness and thermal stability, making them a preferred choice for calibration and quality control in metrology labs.

Key Differences Between Surface Plates and Granite Tables

Surface plates and granite tables serve as precision flat reference surfaces, but surface plates are typically made from cast iron or ceramic for higher rigidity and wear resistance, while granite tables are crafted from natural granite offering superior thermal stability and non-magnetic properties. Surface plates are often used in metrology labs for calibration and inspection due to their higher accuracy and resistance to abrasion, whereas granite tables are preferred in workshops for assembly and layout tasks because of their durability and resistance to corrosion. The primary differences lie in material composition, precision grade, and optimal application environments, with surface plates excelling in measurement accuracy and granite tables providing cost-effective, stable work surfaces.

Material Composition: Cast Iron vs. Granite

Surface plates are typically made from cast iron, offering durability and resistance to wear, while granite tables use natural granite, known for its hardness and stability. Granite is less prone to rust and provides better vibration dampening, making it ideal for precision measurements. Your choice between cast iron and granite affects longevity, maintenance, and accuracy in machining or inspection tasks.

Accuracy and Flatness Comparison

Surface plates, traditionally made from cast iron, provide high accuracy and flatness suitable for precision measurement tasks, yet granite tables often surpass them due to granite's exceptional stability and resistance to wear and corrosion. Granite's natural hardness ensures minimal deformation over time, maintaining flatness within microns, which enhances consistency in your calibration and inspection processes. Choosing a granite table improves reliability and long-term accuracy compared to standard surface plates, especially in environments demanding stringent measurement standards.

Durability and Maintenance Needs

Granite tables offer superior durability due to their high resistance to wear, corrosion, and temperature changes, making them ideal for precision measurement and machining tasks. Surface plates, commonly made from cast iron or ceramic materials, require regular maintenance such as resurfacing and cleaning to prevent rust and wear, which can affect accuracy. Granite's low porosity and natural hardness minimize maintenance needs, ensuring long-term stability and reliability in industrial applications.

Applications in Precision Engineering

Surface plates and granite tables serve as foundational tools in precision engineering for inspection, layout, and measurement tasks requiring high accuracy. Granite tables provide superior flatness, thermal stability, and resistance to wear, making them ideal for applications such as tool calibration, coordinate measuring machines (CMM), and surface roughness testing. Surface plates, often made from cast iron or other metals, are extensively used for faster setups and general purpose gauging, but granite's non-magnetic and corrosion-resistant properties enhance precision in advanced metrology and quality control environments.

Cost Evaluation: Surface Plate vs. Granite Table

Surface plates typically cost less than granite tables, making them a budget-friendly choice for many precision measurement applications. Granite tables offer superior durability and stability but come at a higher initial investment, reflecting their premium material and manufacturing quality. Evaluating total cost of ownership, including maintenance and lifespan, often positions granite tables as more cost-effective in the long term despite the higher upfront expense.

Factors to Consider When Choosing

When choosing between a surface plate and a granite table, consider the material's hardness and stability, as granite offers superior wear resistance and thermal stability compared to cast iron or steel surface plates. Precision requirements and application type are critical, with granite tables preferred for high-accuracy measurement and inspection tasks due to their low thermal expansion. Budget constraints and maintenance needs also influence the decision; granite demands less upkeep and retains flatness longer, making it cost-effective over time.

Pros and Cons of Surface Plates

Surface plates offer exceptional flatness and stability, making them ideal for precision measurement tasks in manufacturing and quality control. Your choice benefits from their durability and wear resistance, but they can be heavier and more expensive than granite tables. However, surface plates require regular calibration to maintain accuracy, which can add to long-term maintenance costs.

Pros and Cons of Granite Tables

Granite tables provide superior durability and exceptional flatness, making them ideal for precision measurement and inspection tasks. Their resistance to wear, corrosion, and temperature changes ensures long-term stability, but granite's heavier weight and higher cost can limit portability and require proper support. You benefit from granite tables' reliable surface for critical applications, yet must consider maintenance and budget constraints when choosing between granite and traditional surface plates.

Surface plate vs granite table Infographic

libmatt.com

libmatt.com