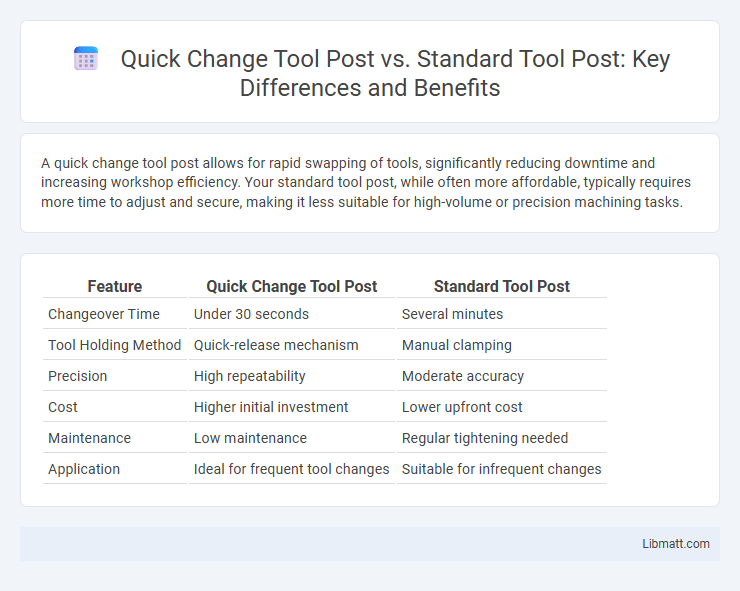

A quick change tool post allows for rapid swapping of tools, significantly reducing downtime and increasing workshop efficiency. Your standard tool post, while often more affordable, typically requires more time to adjust and secure, making it less suitable for high-volume or precision machining tasks.

Table of Comparison

| Feature | Quick Change Tool Post | Standard Tool Post |

|---|---|---|

| Changeover Time | Under 30 seconds | Several minutes |

| Tool Holding Method | Quick-release mechanism | Manual clamping |

| Precision | High repeatability | Moderate accuracy |

| Cost | Higher initial investment | Lower upfront cost |

| Maintenance | Low maintenance | Regular tightening needed |

| Application | Ideal for frequent tool changes | Suitable for infrequent changes |

Introduction to Tool Posts

Quick change tool posts offer enhanced efficiency by allowing rapid tool swapping without the need for realignment, significantly reducing machine downtime compared to standard tool posts. Standard tool posts maintain a fixed tool setup that requires manual adjustment and tightening, which can slow production processes and affect precision. Your choice between quick change and standard tool posts directly impacts operational speed and machining accuracy in a workshop setting.

What is a Quick Change Tool Post?

A Quick Change Tool Post is a specialized tool holder designed to significantly reduce downtime in machining by allowing rapid swapping of cutting tools without the need for extensive adjustments. Unlike standard tool posts, which require manual tightening and precise repositioning for each tool change, quick change models feature a lever or cam mechanism that securely locks tools in place almost instantly. This innovation enhances Your productivity and machining accuracy by ensuring consistent tool positioning and minimizing setup time.

What is a Standard Tool Post?

A Standard Tool Post is a basic machine tool accessory designed to hold cutting tools securely on a lathe. It features a simple clamping mechanism that requires manual adjustment to change tools, often resulting in longer setup times. Compared to Quick Change Tool Posts, Standard Tool Posts lack rapid interchangeability but offer robust rigidity suitable for heavy-duty machining.

Key Differences: Quick Change vs Standard Tool Posts

Quick change tool posts enable faster tool swapping with a lever-operated mechanism, improving machining efficiency compared to the manually tightened standard tool posts. Standard tool posts offer more rigidity and durability for heavy-duty milling tasks, but their slower changeover rates impact productivity in high-volume production. The quick change system typically supports multiple tool holders, facilitating versatile operations without compromising precision.

Installation Process Comparison

Quick change tool posts offer a simplified installation process, allowing you to swap tools rapidly without extensive adjustments, making them ideal for increasing machining efficiency. Standard tool posts require more time and effort to mount and align each tool, involving manual tightening and precise positioning for stability. The quick change system minimizes downtime, enabling faster setup and tool changes compared to the more labor-intensive installation of standard tool posts.

Tool Changing Speed and Efficiency

Quick change tool posts significantly enhance tool changing speed by allowing rapid tool swaps without time-consuming adjustments, boosting your machining efficiency. Unlike standard tool posts, which require loosening and re-tightening for every tool change, quick change systems streamline the process with pre-set tool holders. This reduction in setup time leads to higher productivity and minimizes downtime during operations.

Precision and Repeatability

Quick change tool posts offer superior precision and repeatability compared to standard tool posts by enabling rapid tool swaps without losing alignment. Their rigid clamping mechanism minimizes tool movement, ensuring consistent positioning for each cut. This precision benefits your machining operations by reducing setup time and enhancing accuracy across repetitive tasks.

Cost Analysis: Initial Investment and Maintenance

Quick change tool posts require a higher initial investment compared to standard tool posts but significantly reduce setup time and increase productivity. Maintenance costs for quick change systems tend to be lower due to easier tool swaps and less wear on components, while standard tool posts may incur higher ongoing expenses related to frequent adjustments and tool alignment. Evaluating your machining volume and precision needs helps determine whether your budget aligns better with the long-term savings of a quick change tool post or the lower upfront cost of a standard tool post.

Suitability for Different Machining Operations

Quick change tool posts offer superior versatility and rapid tool swapping, making them ideal for frequent tool changes and complex machining operations requiring multiple tool types. Standard tool posts provide robust stability suited for heavy-duty turning and grooving applications but lack the efficiency in tool change speed. The choice depends on machining needs: quick change tool posts excel in operations demanding flexibility, while standard tool posts are better for consistent, high-precision tasks.

Which Tool Post is Best for You?

Quick change tool posts offer faster tooling swaps and improved productivity by minimizing setup time, making them ideal for professional machinists or high-volume operations. Standard tool posts provide greater rigidity and stability, which can result in better surface finishes and precision, favored for heavy-duty cutting or intricate work. Your choice depends on whether you prioritize efficiency and convenience or maximum accuracy and strength in your machining tasks.

Quick change tool post vs standard tool post Infographic

libmatt.com

libmatt.com