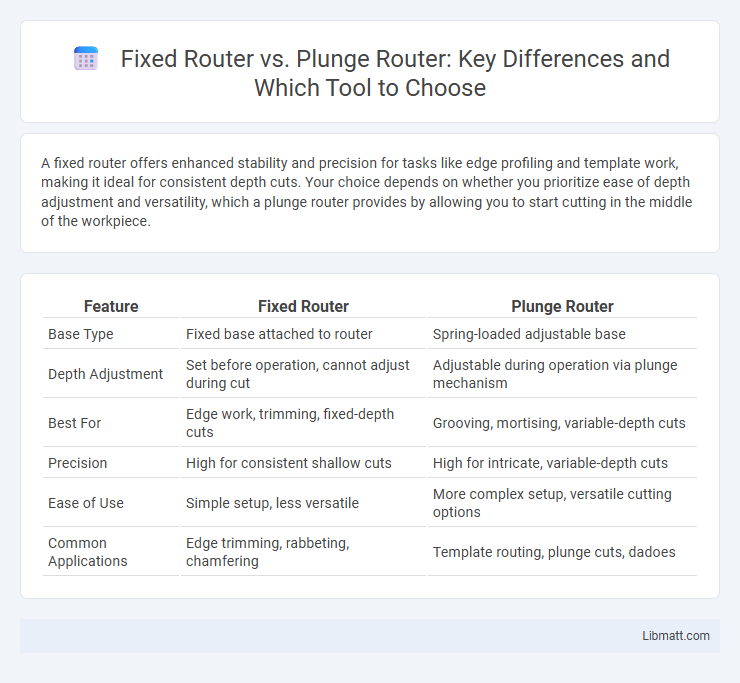

A fixed router offers enhanced stability and precision for tasks like edge profiling and template work, making it ideal for consistent depth cuts. Your choice depends on whether you prioritize ease of depth adjustment and versatility, which a plunge router provides by allowing you to start cutting in the middle of the workpiece.

Table of Comparison

| Feature | Fixed Router | Plunge Router |

|---|---|---|

| Base Type | Fixed base attached to router | Spring-loaded adjustable base |

| Depth Adjustment | Set before operation, cannot adjust during cut | Adjustable during operation via plunge mechanism |

| Best For | Edge work, trimming, fixed-depth cuts | Grooving, mortising, variable-depth cuts |

| Precision | High for consistent shallow cuts | High for intricate, variable-depth cuts |

| Ease of Use | Simple setup, less versatile | More complex setup, versatile cutting options |

| Common Applications | Edge trimming, rabbeting, chamfering | Template routing, plunge cuts, dadoes |

Introduction to Fixed and Plunge Routers

Fixed routers feature a stationary base that provides consistent depth control, making them ideal for edge work and precise groove cutting. Plunge routers allow the bit to be lowered into the material during operation, offering flexibility for creating mortises and interior cuts. Both router types are essential for woodworking, with fixed routers excelling in stability and plunge routers providing versatility for complex tasks.

What is a Fixed Router?

A fixed router features a bit securely mounted in a fixed base, providing stability and precision for straight, shallow cuts in woodworking. It excels in edge profiling, dadoes, and rabbets where consistent depth control is essential. Your choice of a fixed router is ideal when repetitive, uniform cuts are required without adjusting the bit's plunge depth mid-operation.

What is a Plunge Router?

A plunge router features a spring-loaded base that allows the bit to be lowered into the material precisely, ideal for making deep cuts and internal grooves without starting from an edge. Unlike fixed routers, which have a set depth for cutting, plunge routers offer adjustable depth control, enhancing versatility for intricate woodworking tasks. This design enables smooth, controlled plunging into the workpiece, making it essential for applications like mortising and template routing.

Key Differences Between Fixed and Plunge Routers

Fixed routers have their motors permanently mounted beneath the base, offering consistent cutting depth and stability ideal for edge work and precise groove cutting, while plunge routers feature a spring-loaded base allowing the bit to move vertically for adjustable depth during operation, perfect for mortising and template work. The key difference lies in the operational flexibility: fixed routers maintain a set cutting depth, enhancing control for repeatable cuts, whereas plunge routers enable depth changes mid-cut, providing versatility for complex woodworking tasks. Fixed routers excel in applications requiring a steady plunge depth, and plunge routers are preferred when variable depth control and the ability to start cuts in the workpiece center are necessary.

Advantages of Fixed Routers

Fixed routers offer superior stability and precision, making them ideal for detailed woodworking tasks and consistent depth control. Their design allows you to securely mount the router in a table, providing hands-free operation that enhances safety and accuracy. This setup is perfect for repetitive cuts and creating intricate joinery with minimal effort.

Advantages of Plunge Routers

Plunge routers offer greater versatility by allowing you to start cuts in the middle of a workpiece with precision and ease. Their adjustable depth control enables smooth, incremental cutting, ideal for creating grooves, mortises, and dadoes. This makes plunge routers especially advantageous for intricate woodworking projects requiring detailed edge or interior cuts.

Common Applications for Fixed Routers

Fixed routers excel in applications requiring precise, repeatable cuts such as edge profiling, dadoes, and mortises commonly used in cabinetry and furniture making. Their stable base allows for consistent depth control, ideal for intricate joinery and template routing tasks. Frequently utilized for trimming laminates and shaping decorative moldings, fixed routers provide reliable performance in woodworking shops and production environments.

Common Uses for Plunge Routers

Plunge routers are commonly used for creating precise grooves, dados, and mortises in woodworking projects where the router bit needs to start in the middle of the material. These routers excel in tasks like decorative inlays, hinge mortising, and template work, offering controlled depth adjustments during operation. Their design allows craftsmen to plunge the bit into the workpiece, making them ideal for tasks requiring exact depth control and versatility.

How to Choose the Right Router for Your Project

Selecting the right router depends on the specific needs of your woodworking project. Fixed routers provide consistent depth control and are ideal for edge routing, dados, and templates, offering precision for repetitive tasks. Plunge routers allow adjustable depth while cutting, making them versatile for mortising, inlay, and detailed plunge cuts, so assess your project's complexity and desired control to determine which router fits your requirements.

Fixed Router vs Plunge Router: Which One Should You Buy?

A fixed router offers precise depth control for edge-forming and slot-cutting tasks, making it ideal for repetitive woodworking jobs requiring consistent depth. Plunge routers provide versatility by allowing the bit to be lowered into the material mid-cut, perfect for mortising, inlaying, and creating grooves within the workpiece. Choosing between a fixed router and a plunge router depends on the specific woodworking applications and the need for depth adjustability and cutting flexibility.

Fixed router vs plunge router Infographic

libmatt.com

libmatt.com