A drum sander uses a rotating drum covered with sandpaper to smooth large, flat surfaces quickly and evenly, making it ideal for refinishing tabletops and floors. Your choice between a drum sander and a spindle sander depends on the project's shape and detail, as spindle sanders are designed for precise edge and contour sanding on curved and irregular surfaces.

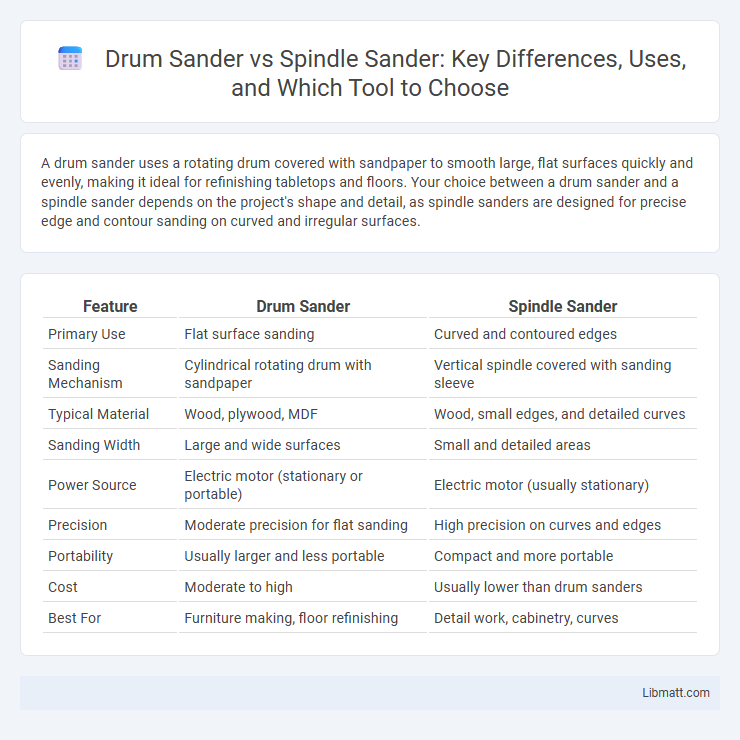

Table of Comparison

| Feature | Drum Sander | Spindle Sander |

|---|---|---|

| Primary Use | Flat surface sanding | Curved and contoured edges |

| Sanding Mechanism | Cylindrical rotating drum with sandpaper | Vertical spindle covered with sanding sleeve |

| Typical Material | Wood, plywood, MDF | Wood, small edges, and detailed curves |

| Sanding Width | Large and wide surfaces | Small and detailed areas |

| Power Source | Electric motor (stationary or portable) | Electric motor (usually stationary) |

| Precision | Moderate precision for flat sanding | High precision on curves and edges |

| Portability | Usually larger and less portable | Compact and more portable |

| Cost | Moderate to high | Usually lower than drum sanders |

| Best For | Furniture making, floor refinishing | Detail work, cabinetry, curves |

Introduction to Drum Sanders and Spindle Sanders

Drum sanders feature a rotating cylindrical drum covered with abrasive material, ideal for smoothing large flat wood surfaces quickly and evenly. Spindle sanders utilize a vertical, oscillating spindle wrapped with sandpaper, specifically designed for sanding curves, edges, and intricate shapes with precision. Both tools are essential in woodworking, serving distinct purposes based on the shape and size of the workpiece.

Key Differences Between Drum and Spindle Sanders

Drum sanders feature a rotating cylindrical drum covered with sandpaper designed for smoothing large, flat surfaces quickly, while spindle sanders use a spinning spindle covered with sandpaper to sand curves and intricate edges with precision. Drum sanders provide consistent thickness and flatness for woodworking projects, whereas spindle sanders excel in detail work, such as sanding inside curves and tight corners. Choosing between these tools depends on whether the task requires high-capacity surface sanding or detailed edge shaping.

How Drum Sanders Work

Drum sanders operate by rotating a cylindrical drum covered with sandpaper at high speeds while feeding the wood piece underneath, enabling smooth and even surface sanding. The drum's adjustable height controls the depth of cut, ensuring precise material removal and consistent finish. This mechanism is ideal for flattening large, rough boards and achieving uniform thickness across the entire workpiece.

How Spindle Sanders Work

Spindle sanders operate by rotating a cylindrical spindle covered with abrasive sandpaper vertically while oscillating it up and down to evenly smooth contours and curves. The oscillating motion reduces heat buildup and prevents sanding marks, allowing precise shaping of intricate wooden edges and detailed surfaces. Unlike drum sanders, spindle sanders excel at finishing irregular shapes, making them essential for fine woodworking and detailed craftsmanship.

Surface Finishing Capabilities Comparison

Drum sanders excel in surface finishing by providing smooth, even sanding across large, flat surfaces with consistent grit contact, making them ideal for removing material quickly and achieving uniform finishes. Spindle sanders offer superior precision for detailed work, efficiently sanding curved edges and intricate shapes while minimizing the risk of over-sanding due to their rotating drum and oscillating spindle mechanism. Your choice between a drum sander and spindle sander will depend on whether you prioritize broad surface finishing speed or detailed edge smoothing for your woodworking projects.

Ideal Applications for Drum Sanders

Drum sanders excel at smoothing large, flat wooden surfaces quickly and efficiently, making them ideal for preparing tabletops, doors, and wide panels for finishing. Their powerful sanding drum and adjustable depth settings enable precise thicknessing and surface leveling, perfect for removing stock or flattening warped boards. Your woodworking projects benefit from a drum sander's ability to deliver uniform finishes on sizable, flat workpieces, which spindle sanders are less suited for due to their smaller sanding drums and contoured applications.

Ideal Applications for Spindle Sanders

Spindle sanders are ideal for sanding intricate curves, inside contours, and irregular shapes, making them perfect for detailed woodworking projects such as chair legs and decorative cutouts. Their compact, vertical sanding drum allows precise control in tight spaces, ensuring smooth finishes on curved edges. These sanders are preferred for tasks that demand accuracy and delicate handling over large surface material removal.

Pros and Cons of Drum Sanders

Drum sanders offer fast, aggressive material removal ideal for flattening large surfaces and leveling uneven boards, but they can be challenging to control for beginners, sometimes causing gouges or uneven sanding. They excel in smoothing rough lumber quickly and maintaining consistent thickness, making them perfect for professional woodworkers handling multiple boards, though the setup and maintenance require careful attention. Your choice should weigh the drum sander's efficiency and surface quality against the risk of less precision and potential tear-out on delicate edges.

Pros and Cons of Spindle Sanders

Spindle sanders excel at precision sanding and finishing of curves and contours, making them ideal for detailed woodworking projects. Their compact design and ability to use various sanding sleeves offer versatility, but they have limited surface area coverage and slower material removal compared to drum sanders. Your choice of a spindle sander ensures finer control and smoother results on intricate edges, while sacrificing speed and efficiency on larger flat surfaces.

Choosing the Right Sander for Your Woodworking Needs

Selecting the right sander for your woodworking projects depends on the type of sanding required; a drum sander excels in flattening large, flat surfaces with consistent thickness, while a spindle sander is ideal for smoothing curves and contours with precision. Your choice should consider the scale of the workpiece, the desired finish, and the specific application, as drum sanders handle heavy stock removal and uniformity, whereas spindle sanders provide control in detailed, curved areas. Evaluating these factors ensures you optimize your tools for efficiency and quality in woodworking tasks.

Drum sander vs spindle sander Infographic

libmatt.com

libmatt.com