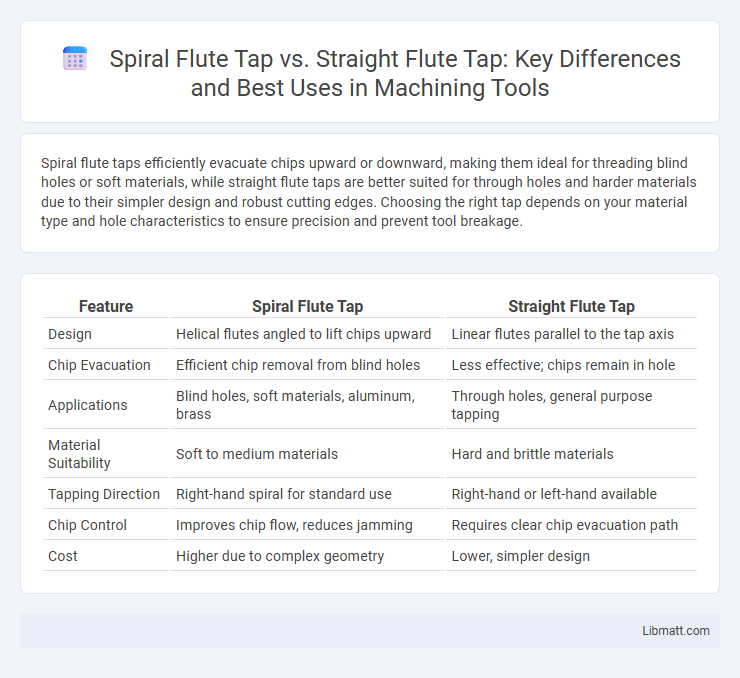

Spiral flute taps efficiently evacuate chips upward or downward, making them ideal for threading blind holes or soft materials, while straight flute taps are better suited for through holes and harder materials due to their simpler design and robust cutting edges. Choosing the right tap depends on your material type and hole characteristics to ensure precision and prevent tool breakage.

Table of Comparison

| Feature | Spiral Flute Tap | Straight Flute Tap |

|---|---|---|

| Design | Helical flutes angled to lift chips upward | Linear flutes parallel to the tap axis |

| Chip Evacuation | Efficient chip removal from blind holes | Less effective; chips remain in hole |

| Applications | Blind holes, soft materials, aluminum, brass | Through holes, general purpose tapping |

| Material Suitability | Soft to medium materials | Hard and brittle materials |

| Tapping Direction | Right-hand spiral for standard use | Right-hand or left-hand available |

| Chip Control | Improves chip flow, reduces jamming | Requires clear chip evacuation path |

| Cost | Higher due to complex geometry | Lower, simpler design |

Introduction to Spiral and Straight Flute Taps

Spiral flute taps feature helical grooves designed to efficiently evacuate chips upward during threading, making them ideal for blind holes and softer materials such as aluminum and plastics. Straight flute taps have parallel grooves that push chips downward or sideways, providing better control and suitability for through holes and harder materials like steel and cast iron. Choosing between spiral and straight flute taps depends on factors like hole type, material, and chip removal requirements to optimize threading performance and tool life.

Design Differences Between Spiral and Straight Flute Taps

Spiral flute taps feature curved flutes that efficiently eject chips upward, ideal for blind holes and soft materials, contrasting with straight flute taps that have linear grooves designed for general-purpose threading and better chip control in through holes. The spiral design enhances chip evacuation and reduces clogging, while straight flutes provide more rigidity and versatility across various materials. Material type and hole depth predominantly influence the choice between spiral and straight flute taps due to these design distinctions.

Cutting Mechanism and Chip Removal

Spiral flute taps utilize a helical cutting edge that efficiently evacuates chips by lifting them out of the hole, preventing clogging and reducing friction during threading, which is ideal for blind holes. Straight flute taps cut chips with a linear edge, pushing chips forward or backward depending on the hole type, making them suitable for through holes but more prone to chip clogging in blind holes. The spiral design enhances cutting action by providing smoother chip flow and improved thread quality compared to the more traditional straight flute mechanism.

Material Compatibility: When to Use Each Tap

Spiral flute taps are ideal for soft, ductile materials like aluminum, copper, and plastics, as the spiral design efficiently evacuates chips upwards, preventing clogging and ensuring smoother threads. Straight flute taps suit harder and more brittle materials such as steel or cast iron, providing better control and reducing the risk of tap breakage by directing chips out of the hole axially. Choose your tap based on material compatibility to improve thread quality and tool life, optimizing your machining process.

Performance in Blind vs. Through Holes

Spiral flute taps excel in blind hole applications by efficiently evacuating chips away from the cutting area, reducing chip clogging and improving thread quality, whereas straight flute taps are better suited for through holes where chips can exit freely. The spiral flute design minimizes the risk of tool breakage and enhances cutting performance in confined blind holes, making it ideal for materials prone to producing long continuous chips. Understanding these differences can help you select the appropriate tap for your threading needs, ensuring optimal machining efficiency and precision.

Speed and Efficiency Comparison

Spiral flute taps offer faster chip evacuation compared to straight flute taps, enhancing speed in deep hole tapping and reducing tool wear. Straight flute taps provide better control and thread accuracy in shallow holes or harder materials but operate at slower feed rates. Overall, spiral flute taps improve efficiency in high-volume production by minimizing cycle times and maintaining thread quality.

Surface Finish and Thread Quality

Spiral flute taps produce superior surface finishes and thread quality due to their chip evacuation design, which reduces material buildup and prevents thread distortion. Straight flute taps tend to generate more friction and heat, leading to rougher surfaces and less precise threads, especially in blind holes or softer materials. The spiral flute's ability to pull chips upward enhances thread consistency and reduces the need for rework in critical applications.

Tool Life and Maintenance

Spiral flute taps generally offer longer tool life due to efficient chip evacuation, reducing heat and wear compared to straight flute taps. Your maintenance routine becomes simpler with spiral flute taps as they experience less frequent clogging and damage, minimizing downtime. Straight flute taps require more frequent inspection and cleaning to maintain performance, especially in softer materials where chip removal is less efficient.

Cost Considerations and Value

Spiral flute taps generally cost more than straight flute taps due to their more complex design and enhanced chip evacuation capabilities, which improve efficiency and reduce downtime in CNC machining. Despite the higher initial investment, spiral flute taps offer greater tool life and superior performance in blind hole threading applications, translating to lower overall production costs. Straight flute taps are more economical for simple threading tasks with through holes, providing sufficient value in less demanding manufacturing environments.

Choosing the Right Flute Tap for Your Application

Selecting the right flute tap depends on the material and chip evacuation requirements of your application; spiral flute taps are ideal for blind holes and soft materials like aluminum due to their efficient chip removal and reduced risk of clogging. Straight flute taps are better suited for through holes and harder materials such as steel, providing durability and ease of use. Understanding the workpiece characteristics and hole type ensures optimal tap performance and prolongs tool life.

Spiral flute tap vs straight flute tap Infographic

libmatt.com

libmatt.com