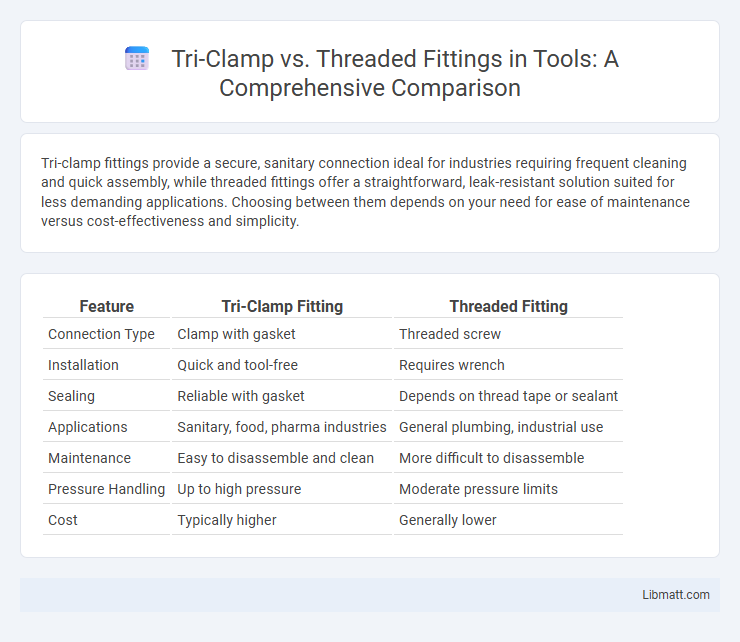

Tri-clamp fittings provide a secure, sanitary connection ideal for industries requiring frequent cleaning and quick assembly, while threaded fittings offer a straightforward, leak-resistant solution suited for less demanding applications. Choosing between them depends on your need for ease of maintenance versus cost-effectiveness and simplicity.

Table of Comparison

| Feature | Tri-Clamp Fitting | Threaded Fitting |

|---|---|---|

| Connection Type | Clamp with gasket | Threaded screw |

| Installation | Quick and tool-free | Requires wrench |

| Sealing | Reliable with gasket | Depends on thread tape or sealant |

| Applications | Sanitary, food, pharma industries | General plumbing, industrial use |

| Maintenance | Easy to disassemble and clean | More difficult to disassemble |

| Pressure Handling | Up to high pressure | Moderate pressure limits |

| Cost | Typically higher | Generally lower |

Introduction to Tri-Clamp and Threaded Fittings

Tri-Clamp fittings feature a sanitary design commonly used in food, beverage, and pharmaceutical industries for secure, leak-proof connections. Threaded fittings rely on screw threads for connection, providing a versatile and cost-effective solution in plumbing and industrial applications. Your choice depends on the need for easy cleaning and quick assembly (Tri-Clamp) versus durability and compatibility with threaded piping systems.

Key Features of Tri-Clamp Fittings

Tri-clamp fittings are characterized by their quick-release clamp mechanism that enables easy assembly and disassembly, making them ideal for sanitary applications in food, beverage, and pharmaceutical industries. These fittings provide a secure, leak-proof seal with a smooth, crevice-free surface that minimizes bacterial growth and contamination risk. Made typically from stainless steel, tri-clamp fittings offer excellent corrosion resistance and durability under high-pressure and high-temperature conditions.

Key Features of Threaded Fittings

Threaded fittings feature spiral grooves on male and female ends that securely connect piping components through twisting, providing a reliable seal without welding. Commonly made from stainless steel or brass, they offer easy assembly and disassembly for maintenance or system modifications. Their design supports various pressure ratings and sizes, making them versatile for plumbing, gas, and fluid transfer applications.

Material Compatibility and Construction

Tri-clamp fittings feature a smooth, crevice-free design made typically from stainless steel, ensuring high material compatibility with sanitary and corrosive environments, ideal for food, beverage, and pharmaceutical industries. Threaded fittings, often composed of materials like brass, stainless steel, or carbon steel, offer durable construction but may harbor crevices that can trap contaminants, affecting compatibility with hygienic or sensitive applications. Your choice between the two should consider the material's resistance to chemicals, ease of cleaning, and industry standards to ensure optimal performance and safety.

Installation and Maintenance Comparison

Tri-clamp fittings offer quick installation with a simple clamp mechanism reducing labor time, making them ideal for frequent disassembly and cleaning in sanitary applications. Threaded fittings require careful alignment and sealing with thread tape or sealant to prevent leaks, leading to longer installation times and potential maintenance challenges due to thread wear or corrosion. The ease of cleaning and reduced downtime with Tri-clamp fittings often results in lower long-term maintenance costs compared to the more rigid and potentially leak-prone threaded fittings.

Cleanliness and Sanitary Requirements

Tri-clamp fittings offer superior cleanliness and meet stringent sanitary requirements due to their smooth, crevice-free design that prevents bacterial buildup and is easy to sanitize, making them ideal for food, beverage, and pharmaceutical applications. Threaded fittings have threads that can trap contaminants and are harder to clean thoroughly, increasing the risk of contamination in sanitary environments. Your choice should prioritize tri-clamp fittings when strict hygiene and cleanability are critical to maintaining product safety and quality.

Pressure and Temperature Rating Differences

Tri-clamp fittings typically offer superior pressure and temperature ratings compared to threaded fittings, making them ideal for high-pressure sanitary and industrial applications. Tri-clamp connections can handle pressures up to 300 psi and temperatures exceeding 500degF, due to their robust design and use of gaskets that maintain tight seals under extreme conditions. Threaded fittings usually have lower pressure limits, often around 150 psi, and are less suitable for high-temperature environments because their mechanical threads can degrade or loosen under stress.

Application Suitability: Industries and Use Cases

Tri-clamp fittings are ideal for sanitary applications in industries like food and beverage, pharmaceuticals, and biotechnology due to their easy cleaning and secure, leak-free seals. Threaded fittings are better suited for low-pressure systems in industrial piping, oil and gas, and water treatment where quick installation and durability are priorities. Your choice depends on the specific industry standards and the need for hygienic conditions versus robust mechanical connections.

Cost Considerations and Budget Impact

Tri-clamp fittings typically have a higher upfront cost compared to threaded fittings due to their stainless steel construction and ease of assembly, which reduces labor time during installation. Threaded fittings are generally more budget-friendly initially but may incur higher maintenance costs over time because of potential leakage and corrosion issues. Evaluating total cost of ownership, including installation, maintenance, and longevity, is critical for making an informed decision between tri-clamp and threaded fitting systems.

Choosing the Right Fitting for Your System

Selecting between tri-clamp and threaded fittings depends on factors like system pressure, hygiene requirements, and ease of maintenance. Tri-clamp fittings offer quick assembly and superior sanitary conditions, making them ideal for food, beverage, and pharmaceutical applications. Threaded fittings provide robust sealing for high-pressure systems but require more effort for disassembly, suitable for industrial environments with less frequent cleaning needs.

Tri-clamp vs threaded fitting Infographic

libmatt.com

libmatt.com