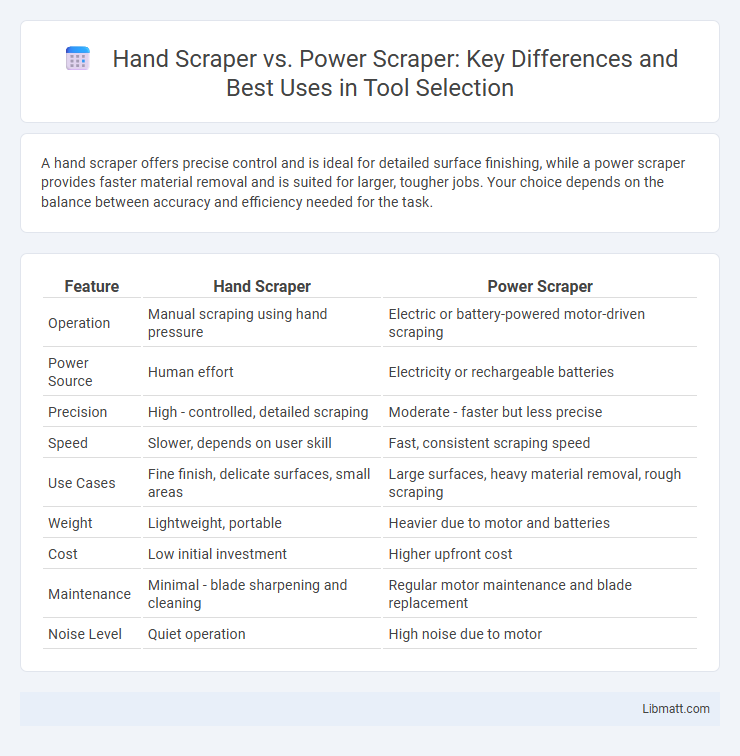

A hand scraper offers precise control and is ideal for detailed surface finishing, while a power scraper provides faster material removal and is suited for larger, tougher jobs. Your choice depends on the balance between accuracy and efficiency needed for the task.

Table of Comparison

| Feature | Hand Scraper | Power Scraper |

|---|---|---|

| Operation | Manual scraping using hand pressure | Electric or battery-powered motor-driven scraping |

| Power Source | Human effort | Electricity or rechargeable batteries |

| Precision | High - controlled, detailed scraping | Moderate - faster but less precise |

| Speed | Slower, depends on user skill | Fast, consistent scraping speed |

| Use Cases | Fine finish, delicate surfaces, small areas | Large surfaces, heavy material removal, rough scraping |

| Weight | Lightweight, portable | Heavier due to motor and batteries |

| Cost | Low initial investment | Higher upfront cost |

| Maintenance | Minimal - blade sharpening and cleaning | Regular motor maintenance and blade replacement |

| Noise Level | Quiet operation | High noise due to motor |

Introduction to Hand Scrapers and Power Scrapers

Hand scrapers are precision tools designed for fine surface finishing and material removal by hand, offering exceptional control for tasks requiring accuracy and smoothness. Power scrapers utilize motorized mechanisms to increase efficiency and speed for larger or tougher surface preparation jobs, reducing manual effort while maintaining consistent results. Choosing between hand scrapers and power scrapers depends on your project's scale, required finish quality, and the balance between precision and productivity.

Key Differences Between Hand Scrapers and Power Scrapers

Hand scrapers offer precise manual control for fine surface finishing and are ideal for small-scale or detailed work, while power scrapers provide faster material removal and efficiency on larger surfaces. Hand scrapers require significant physical effort and skill, whereas power scrapers reduce operator fatigue with motorized operation and adjustable speed settings. Key differences include control precision, operational speed, and suitability for different project scales and surface conditions.

Advantages of Using Hand Scrapers

Hand scrapers offer superior precision and control when removing high spots and imperfections on metal surfaces, making them ideal for fine-tuning and achieving a mirror finish. They require no electricity, reducing operational costs and enabling use in locations without power access. The tactile feedback provided by hand scraping enhances surface flatness and accuracy, which is critical in machine tool alignment and maintenance.

Advantages of Using Power Scrapers

Power scrapers offer increased efficiency by rapidly and evenly removing material from surfaces, significantly reducing manual labor compared to hand scrapers. These tools provide precise control and consistent pressure, which improves surface finish quality and minimizes operator fatigue. Using a power scraper enhances productivity and accuracy, making it an ideal choice for tasks requiring extensive surface preparation or maintenance.

Ideal Use Cases for Hand Scrapers

Hand scrapers excel in precision tasks like fine surface finishing, removing rust, and deburring small or delicate areas where control is essential. You will find them ideal for repairing engine blocks, fitting machine parts, and smoothing castings with minimal material removal. Their manual operation ensures greater accuracy in detailed work compared to power scrapers, which are better for broader, less precise surface preparation.

Ideal Use Cases for Power Scrapers

Power scrapers are ideal for heavy-duty surface preparation tasks such as removing thick layers of paint, rust, or adhesive from large metal or concrete surfaces. They excel in industrial and automotive maintenance environments where efficiency and speed are critical. High torque and variable speed settings allow power scrapers to adapt to diverse materials and ensure consistent, thorough cleaning on extensive projects.

Cost Comparison: Hand Scraper vs Power Scraper

Hand scrapers typically cost between $20 and $100, making them an affordable option for precision work and small-scale projects. Power scrapers range from $150 to $500 or more, reflecting their efficiency and suitability for larger surfaces and heavy-duty tasks. Your choice will depend on budget constraints and the scale of the scraping job, with hand scrapers offering low-cost versatility and power scrapers delivering faster, high-volume results.

Safety Considerations for Both Tools

Hand scrapers offer greater control and lower risk of injury due to their manual operation, reducing chances of accidental slips or overcuts. Power scrapers, while more efficient, require strict adherence to safety protocols such as wearing protective gear and maintaining proper tool handling to prevent high-speed accidents and debris ejection. Proper maintenance and inspection of both tools are essential to ensure secure grips and prevent malfunction-related hazards during use.

Maintenance and Durability Analysis

Hand scrapers require minimal maintenance, primarily regular sharpening and occasional blade replacement, making them highly durable for fine, precise material removal. Power scrapers demand frequent maintenance including motor checks, blade changes, and lubrication to sustain performance, which can impact long-term durability due to mechanical wear. Your choice depends on whether you prioritize low maintenance and longevity (hand scraper) or speed and efficiency with higher upkeep (power scraper).

Choosing the Right Scraper for Your Project

Hand scrapers offer precision and control for detailed surface finishing, ideal for small-scale or delicate projects requiring fine adjustments. Power scrapers excel in efficiency and speed, suited for larger surfaces or heavy material removal where time savings are critical. Selecting the right scraper depends on project scale, surface type, and desired finish quality, balancing accuracy with productivity.

Hand scraper vs power scraper Infographic

libmatt.com

libmatt.com