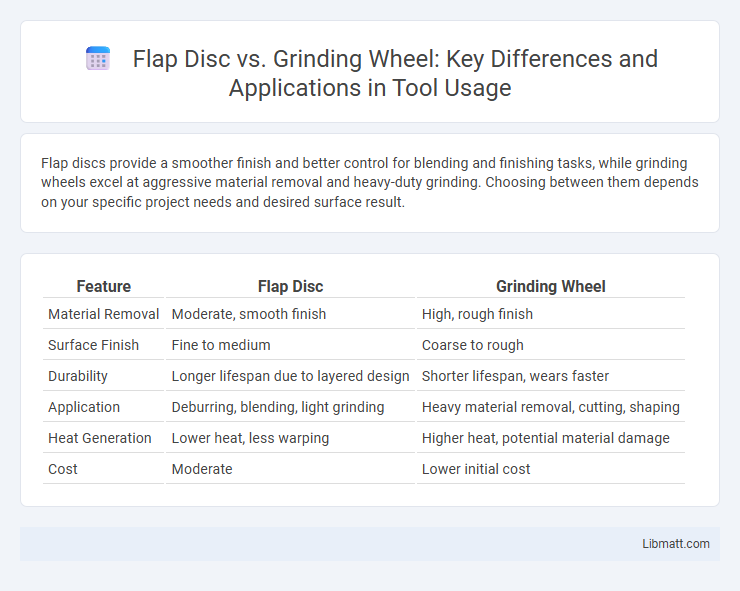

Flap discs provide a smoother finish and better control for blending and finishing tasks, while grinding wheels excel at aggressive material removal and heavy-duty grinding. Choosing between them depends on your specific project needs and desired surface result.

Table of Comparison

| Feature | Flap Disc | Grinding Wheel |

|---|---|---|

| Material Removal | Moderate, smooth finish | High, rough finish |

| Surface Finish | Fine to medium | Coarse to rough |

| Durability | Longer lifespan due to layered design | Shorter lifespan, wears faster |

| Application | Deburring, blending, light grinding | Heavy material removal, cutting, shaping |

| Heat Generation | Lower heat, less warping | Higher heat, potential material damage |

| Cost | Moderate | Lower initial cost |

Introduction: Flap Disc vs Grinding Wheel

Flap discs offer superior versatility and smoother finishes compared to grinding wheels, making them ideal for metal surface blending and finishing tasks. Grinding wheels excel in heavy material removal and high-efficiency grinding, providing aggressive cutting suitable for tough applications. Choosing between flap discs and grinding wheels depends on the specific requirements for precision, surface finish, and material removal rate.

Overview of Flap Discs

Flap discs are abrasive tools composed of multiple overlapping layers of coated abrasive flaps bonded to a central hub, designed for efficient metal finishing and blending. They provide a smoother finish and better control compared to grinding wheels, making them ideal for surface preparation, deburring, and edge grinding on metals like steel and aluminum. Flap discs also offer longer lifespan and reduced vibration, enhancing operator comfort and productivity in industrial and fabrication settings.

Overview of Grinding Wheels

Grinding wheels are abrasive tools used for precise material removal, typically made from bonded abrasive grains like aluminum oxide or silicon carbide. They come in various shapes and sizes, designed for specific applications such as surface grinding, cylindrical grinding, or tool sharpening. Known for their durability and ability to handle heavy-duty grinding tasks, grinding wheels provide consistent performance on hard metals and thick materials.

Key Material Differences

Flap discs consist of multiple overlapping abrasive flaps made of aluminum oxide or zirconia alumina, offering flexibility and consistent material removal while minimizing heat buildup. Grinding wheels are typically composed of a single solid abrasive material such as silicon carbide or aluminum oxide, providing a rigid structure designed for aggressive material removal and heavy-duty grinding tasks. The key material difference lies in the layered abrasive construction of flap discs versus the monolithic abrasive block of grinding wheels, affecting durability, heat resistance, and surface finish quality.

Applications and Use Cases

Flap discs excel in metal fabrication and finishing by providing smooth surface blending and deburring on stainless steel, aluminum, and mild steel. Grinding wheels are preferred for heavy material removal and shaping tasks on hard metals, cast iron, and concrete due to their aggressive cutting action. Flap discs offer versatility in weld seam blending and edge rounding, while grinding wheels deliver precision in cutting, beveling, and rough surface preparation.

Performance Comparison

Flap discs offer superior performance for blending and finishing tasks due to their flexible abrasive flaps that provide a smoother surface and more consistent material removal compared to grinding wheels. Grinding wheels excel in heavy stock removal and precision cutting, but they tend to generate more heat and can leave deeper gouges on the workpiece. Choosing between the two depends on your specific project needs--flap discs for finish quality and versatility, grinding wheels for aggressive grinding and rapid material removal.

Surface Finish and Quality

Flap discs provide a smoother surface finish and higher quality results due to their overlapping abrasive flaps that wear evenly, ensuring consistent material removal. Grinding wheels tend to be more aggressive, often leaving rougher surfaces with potential for heat damage or gouging, making them less ideal for applications requiring precision. Choosing a flap disc can improve your project's overall surface quality and reduce the need for additional finishing steps.

Lifespan and Durability

Flap discs typically offer a longer lifespan than grinding wheels due to their layered abrasive cloth design, which wears away gradually and continuously exposes fresh abrasive material. Grinding wheels are more prone to faster wear and can become uneven or brittle, leading to frequent replacements. The durability of flap discs also enhances consistent performance on metal surfaces, reducing downtime and operational costs.

Cost Efficiency

Flap discs offer superior cost efficiency compared to grinding wheels due to their longer lifespan and ability to provide both grinding and finishing in a single step, reducing the need for multiple tools. The abrasive flaps wear down gradually, exposing fresh material and maintaining performance, which decreases replacement frequency and operational downtime. Grinding wheels, while often cheaper initially, tend to wear out faster and require more frequent changes, increasing overall costs in prolonged projects.

Choosing the Right Tool for Your Project

Selecting the right abrasive tool depends on the specific task requirements, with flap discs offering superior versatility for surface blending, edge rounding, and deburring. Grinding wheels excel in heavy material removal and precise grinding on metal workpieces, making them ideal for aggressive stock removal. Evaluate project needs such as surface finish quality, material type, and removal speed to determine whether a flap disc or grinding wheel is the most efficient choice.

Flap disc vs grinding wheel Infographic

libmatt.com

libmatt.com