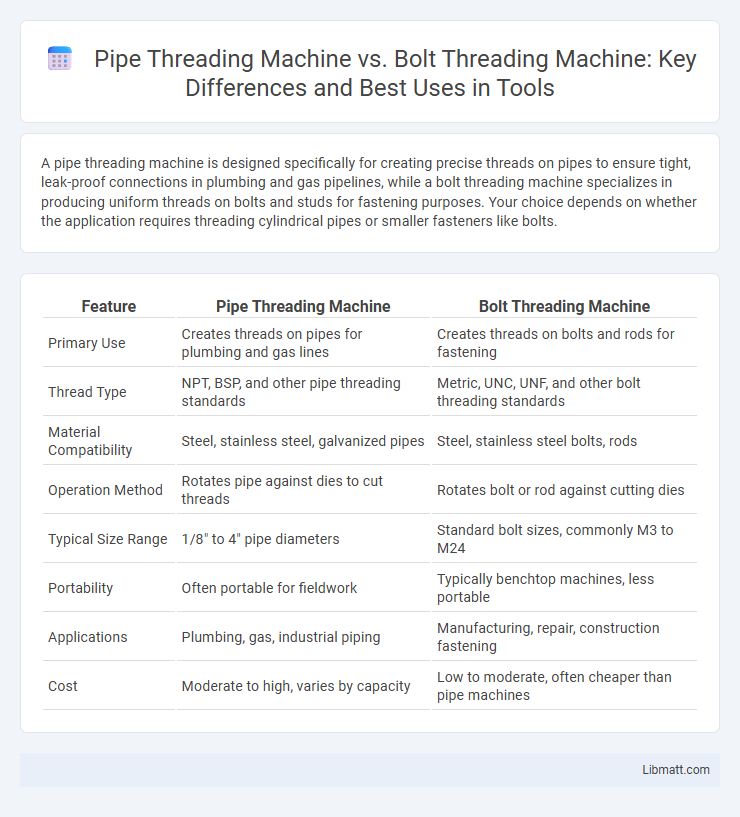

A pipe threading machine is designed specifically for creating precise threads on pipes to ensure tight, leak-proof connections in plumbing and gas pipelines, while a bolt threading machine specializes in producing uniform threads on bolts and studs for fastening purposes. Your choice depends on whether the application requires threading cylindrical pipes or smaller fasteners like bolts.

Table of Comparison

| Feature | Pipe Threading Machine | Bolt Threading Machine |

|---|---|---|

| Primary Use | Creates threads on pipes for plumbing and gas lines | Creates threads on bolts and rods for fastening |

| Thread Type | NPT, BSP, and other pipe threading standards | Metric, UNC, UNF, and other bolt threading standards |

| Material Compatibility | Steel, stainless steel, galvanized pipes | Steel, stainless steel bolts, rods |

| Operation Method | Rotates pipe against dies to cut threads | Rotates bolt or rod against cutting dies |

| Typical Size Range | 1/8" to 4" pipe diameters | Standard bolt sizes, commonly M3 to M24 |

| Portability | Often portable for fieldwork | Typically benchtop machines, less portable |

| Applications | Plumbing, gas, industrial piping | Manufacturing, repair, construction fastening |

| Cost | Moderate to high, varies by capacity | Low to moderate, often cheaper than pipe machines |

Introduction to Threading Machines

Threading machines are specialized tools designed to create precise threads on pipes or bolts, enabling secure fastenings and connections. Pipe threading machines focus on cutting threads on cylindrical pipes for plumbing and construction applications, while bolt threading machines produce threads on bolts for mechanical assembly and repair work. Understanding your specific project requirements will help you choose the right threading machine that ensures efficiency and accuracy.

What is a Pipe Threading Machine?

A pipe threading machine is a specialized tool designed to cut precise threads on the ends of pipes, enabling secure and leak-proof connections in plumbing and industrial applications. It efficiently handles various pipe sizes and materials, ensuring smooth, consistent threads that fit standard pipe fittings. Your projects will benefit from the machine's ability to enhance assembly speed and joint durability compared to manual threading methods.

What is a Bolt Threading Machine?

A bolt threading machine is specialized equipment designed to cut precise threads on bolts, enabling secure fastening in construction and manufacturing applications. Unlike pipe threading machines, which focus on creating threads on pipe ends for fluid or gas connections, bolt threading machines handle solid rods or bars to produce external threads for fasteners. These machines provide high accuracy and consistency in thread pitch and depth, essential for ensuring proper assembly and load-bearing capacity.

Key Differences Between Pipe and Bolt Threading Machines

Pipe threading machines are specifically designed to cut threads on cylindrical pipes, ensuring airtight and watertight seals for plumbing and industrial applications. Bolt threading machines focus on creating precise screw threads on bolts or rods, providing secure fastening solutions in construction and machinery. Your choice depends on the threading requirements: pipe machines handle larger diameters and tapered threads, while bolt machines cater to smaller diameters and standard thread profiles.

Applications: Pipe vs Bolt Threading Machines

Pipe threading machines are designed primarily for creating precise threads on various pipe sizes used in plumbing, gas lines, and construction, ensuring secure connections in fluid and gas systems. Bolt threading machines specialize in producing uniform threads on fasteners like bolts and studs, essential for mechanical assemblies and structural components requiring strong, reliable fastening. Your choice depends on whether you need threaded connections for piping systems or high-strength fastening solutions in manufacturing and construction.

Advantages of Pipe Threading Machines

Pipe threading machines offer superior efficiency in creating precise, durable threads on pipes used in plumbing, gas, and oil industries, enabling seamless pipe connections. These machines handle larger diameters and tougher materials than bolt threading machines, providing versatility for heavy-duty applications. Their automated threading capabilities reduce manual labor and improve consistency, increasing productivity and reducing errors in industrial operations.

Advantages of Bolt Threading Machines

Bolt threading machines offer superior precision when creating uniform threads on bolts, ensuring high-quality fastening performance. They typically provide faster threading speeds, which enhances productivity in manufacturing and repair tasks. Your operations benefit from increased efficiency and consistent thread standards by using bolt threading machines tailored specifically for bolt applications.

Factors to Consider When Choosing a Threading Machine

When choosing between a pipe threading machine and a bolt threading machine, consider the specific application requirements such as thread type, material compatibility, and thread size capacity. Pipe threading machines are ideal for generating precise, tapered threads on various pipe materials including steel and PVC, whereas bolt threading machines excel in producing accurate, full-length threads on rods and bolts of different diameters. Evaluate factors like motor power, portability, threading speed, and ease of die change to ensure efficient operation tailored to the project's industrial or maintenance needs.

Maintenance and Safety Tips for Threading Machines

Pipe threading machines require regular lubrication and inspection of dies to prevent wear and ensure precise threading, while bolt threading machines demand consistent cleaning of cutting tools to avoid buildup and maintain thread accuracy. Both machines benefit from routine checks of power cords, safety guards, and emergency stop functions to reduce electrocution and injury risks. Proper use of personal protective equipment (PPE) such as gloves and eye protection is essential to safeguard operators from metal shavings and rotating parts during threading processes.

Final Verdict: Which Threading Machine is Right for You?

Choosing between a pipe threading machine and a bolt threading machine depends on the specific materials and applications you encounter. Pipe threading machines excel in creating secure, leak-proof threads on pipes used in plumbing and industrial piping systems, while bolt threading machines are designed for precision threading on bolts and rods across construction and manufacturing projects. Your decision should consider the type of threading required, the materials involved, and the operational efficiency each machine offers for your threading needs.

Pipe threading machine vs bolt threading machine Infographic

libmatt.com

libmatt.com